Wind power blade and application thereof

A technology of wind power blades and blade bodies, applied in wind power blades and their application fields, can solve the problems of inability to realize maximum utilization of wind energy, inability to realize effective use of wind energy, inability to absorb wind well, etc., to achieve increased strength and reliable structure performance, long service life, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

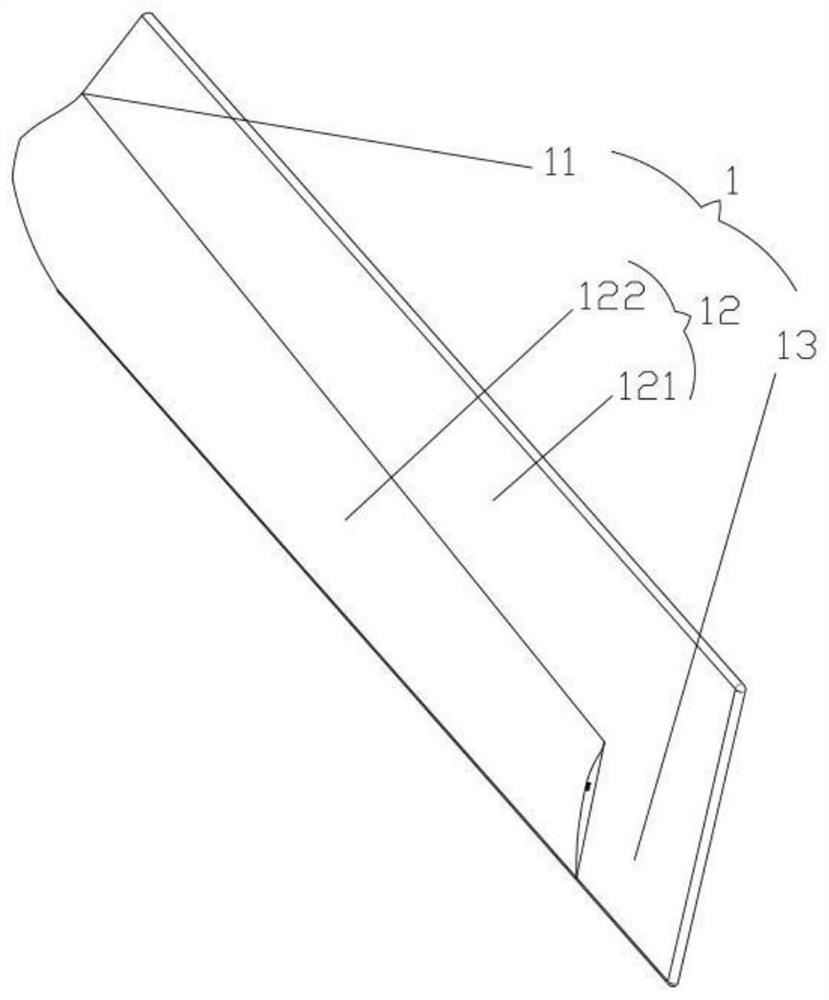

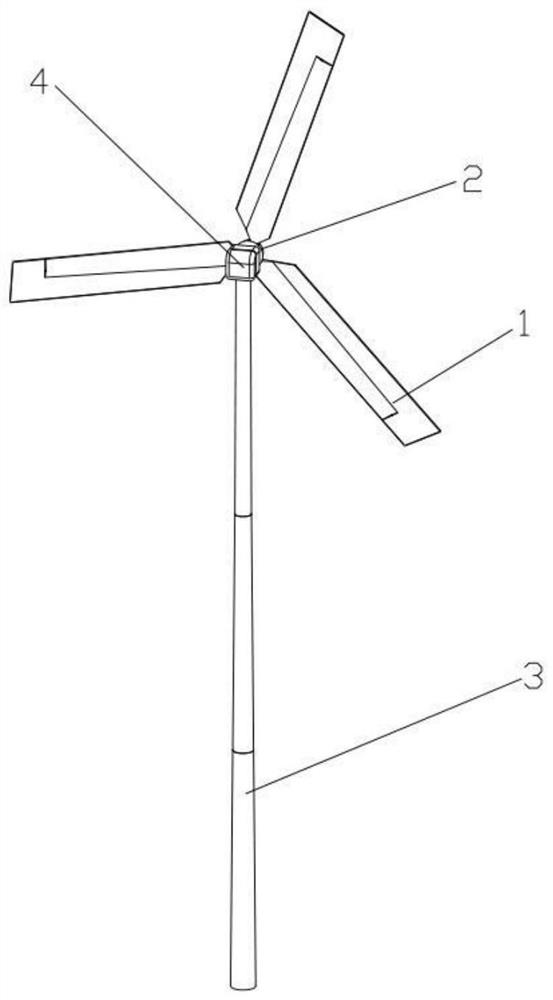

[0023] see figure 1 , 2 , a wind power blade, including a blade body 1, the side of the tail end of the blade body 1 is a planar structure, which increases the wind receiving area of the tail end, increases the resistance of the tail end, and reduces the speed of the wind power blade, but due to the wind suction The capacity is stronger, and the overall power generation efficiency will not be reduced. On the contrary, the noise reduction effect is achieved by reducing the speed of the wind turbine blades.

[0024] The wind power blade of this embodiment is designed as a plane structure on the side of the tail end of the blade body 1 to ensure that the end of the wind power blade has a high structural strength, is not easily damaged by wind force, and has a long service life.

[0025] In this embodiment, after the blade body 1 is installed, the projected side edges along the direction of the rotation axis are all linear structures. The blade body 1 includes a connecting por...

Embodiment 2

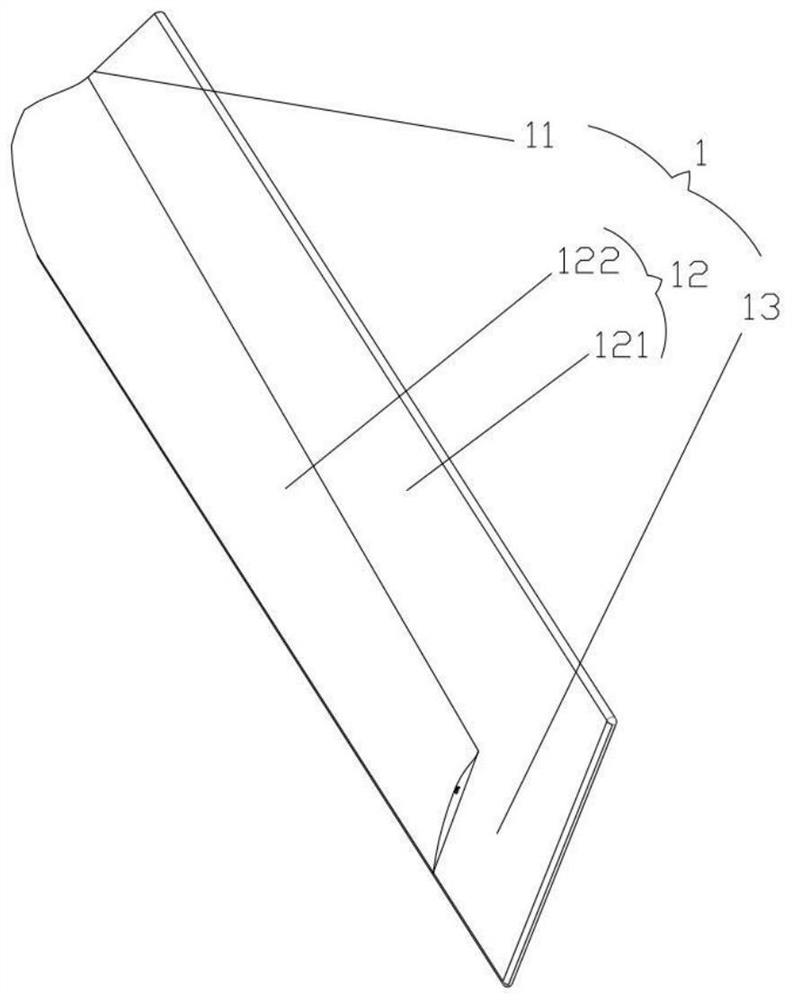

[0031] see image 3 The difference between this embodiment and Embodiment 1 is that the tail end side of the blade body 1 is a curved surface structure, and the blade body 1 is made of aluminum alloy, which is lighter in weight, higher in strength, and higher in wind energy conversion efficiency. , the rest of the structure is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com