Hidden manganese carbonate-rich ore detection method

A technology of manganese carbonate ore and a detection method, which is applied in the field of mineral resource exploration, can solve the problems that the specific location of the hidden manganese carbonate-rich ore body and its extension range cannot be effectively explored, and the exploration efficiency of the hidden ore needs to be improved, so as to improve the exploration efficiency and safety. sex, improve job safety, and reduce working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

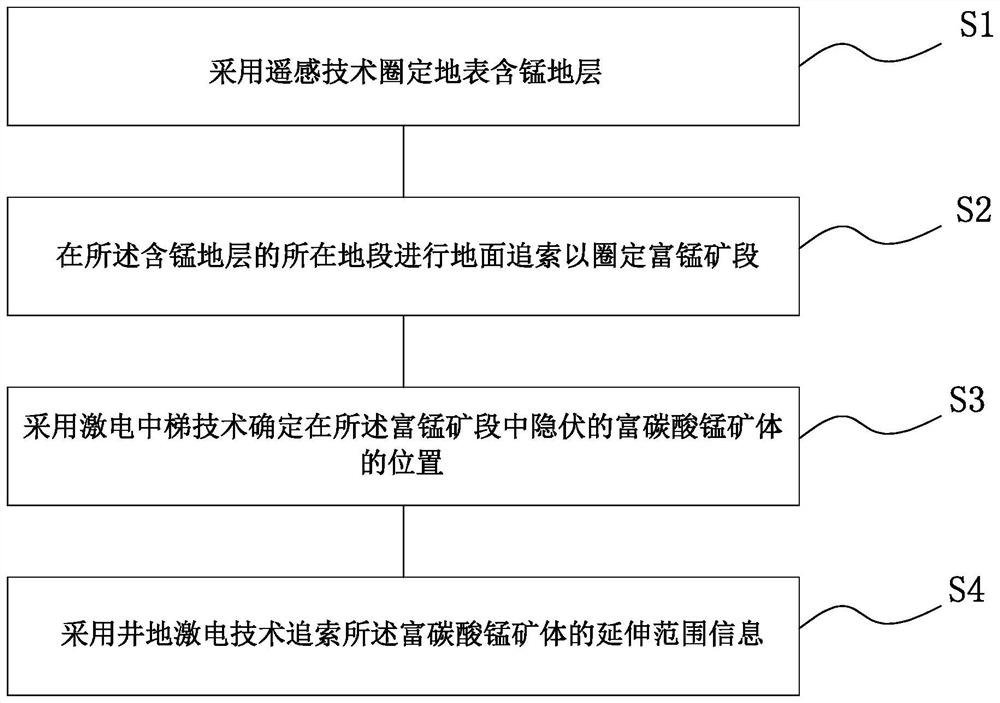

[0055] refer to figure 1 , a detection method for hidden manganese carbonate-rich ore, comprising:

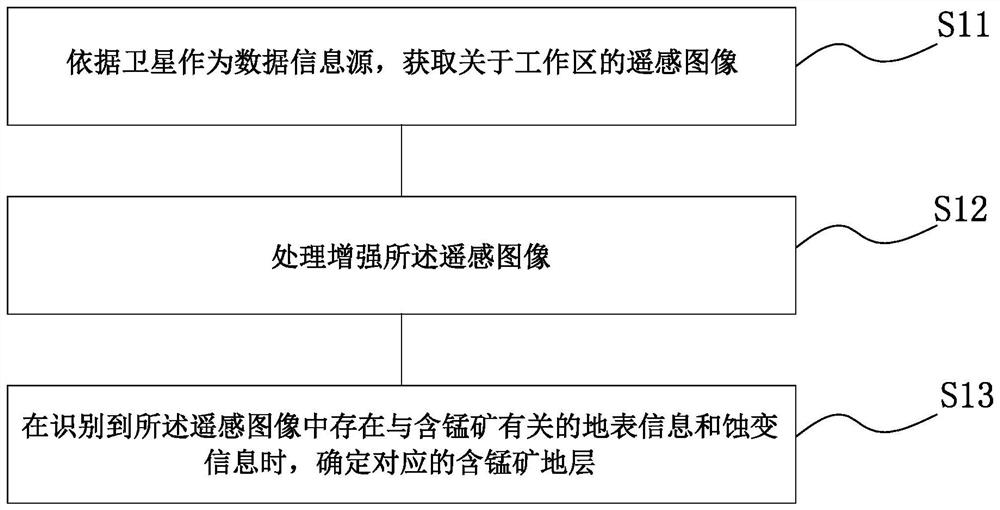

[0056]S1. Use remote sensing technology to delineate the manganese-bearing strata on the surface.

[0057] S2. Carry out ground recourse at the location of the manganese-bearing stratum to determine the manganese-rich ore section.

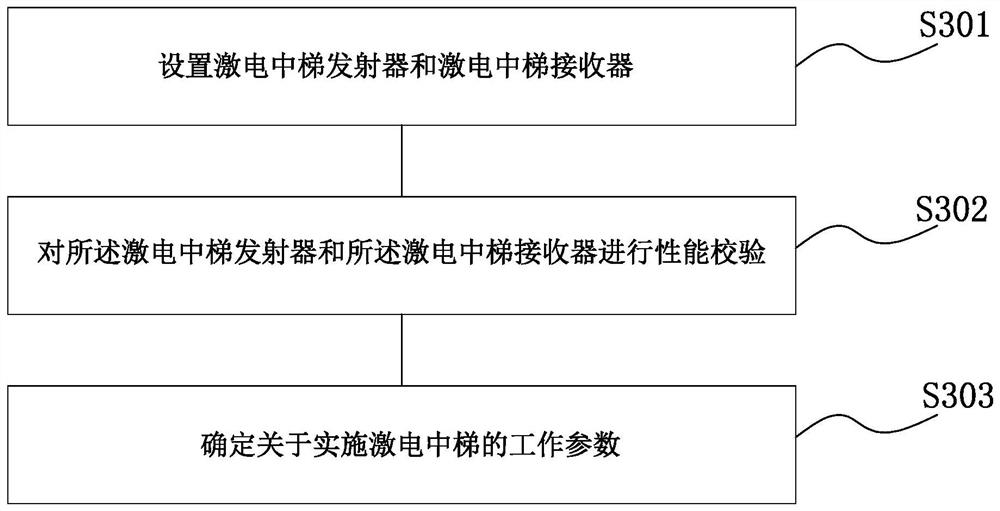

[0058] S3. The position of the concealed manganese carbonate-rich ore body in the manganese-rich ore section is determined by using the induced electric intermediate ladder technology.

[0059] S4. The extension range information of the rich manganese carbonate ore body is traced by using the well-ground IP technology.

[0060] Specifically: the present application uses remote sensing technology to perform non-contact preliminary survey in a preset work area, which is beneficial to reduce the working time of geologists in harsh environments and improve the work safety of geologists. After delineating the manganese-bearing strata on the surface, c...

Embodiment 2

[0097] What is different from embodiment 1 is that in embodiment 2, before the position of the hidden manganese carbonate-rich ore body in the manganese-rich ore section is determined by using the induced electric intermediate ladder technology, the following steps are also included: adopting the wide-area electromagnetic technology. Obtain the stratigraphic depth extension and occurrence of the manganese-rich ore section. i.e. reference Figure 5 , the detection method of the hidden manganese carbonate-rich ore of the present embodiment includes:

[0098] S1. Use remote sensing technology to delineate the manganese-bearing strata on the surface.

[0099] S2. Carry out ground recourse at the location of the manganese-bearing stratum to determine the manganese-rich ore section.

[0100] S3. Use wide-area electromagnetic technology to obtain the stratigraphic depth extension and occurrence of the manganese-rich ore section.

[0101] S4. The position of the concealed manganese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com