Chip surface defect parallel detection method based on improved convolution variational auto-encoder

An autoencoder and detection method technology, applied in image coding, neural learning methods, instruments, etc., can solve the problem of short detection time, and achieve the effect of reducing manpower and material resources, reducing defect detection time, and reducing labor and time costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

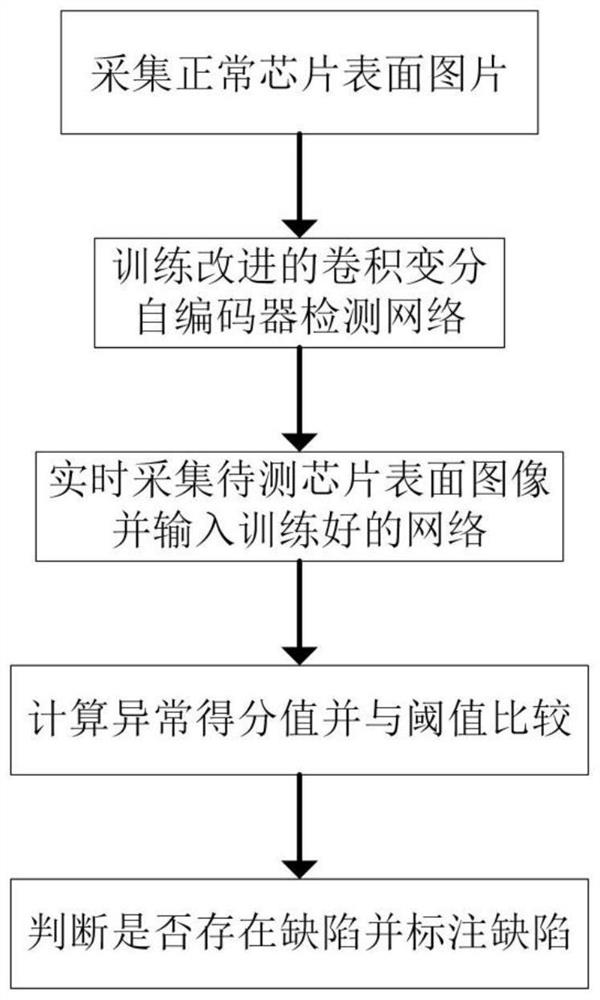

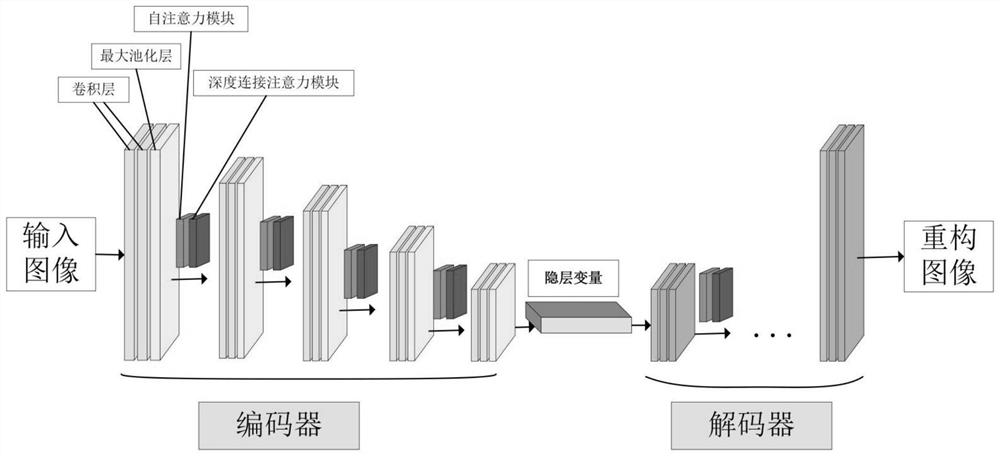

[0015] The method for parallel detection of chip surface defects based on the improved convolutional variational autoencoder of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments: This embodiment includes the following steps:

[0016] S1, chip image acquisition and preprocessing, S2, construction and training of an improved convolutional variational autoencoder, S3, real-time defect detection of the chip to be tested.

[0017] S1 consists of the following steps:

[0018] S1.1. Use the high-definition camera module, the host image processing module and the lighting module to collect and store images for subsequent image processing. In addition, it is equipped with a defect sound and light alarm module to prompt the detection of defective chips. Using a CCD camera, two LED array light sources intersect for fan-shaped dark field illumination.

[0019] S1.2. Collect the surface image of a normal chip, decom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com