Steel ladle tipping device and method

A ladle tipping and ladle technology, which is applied to metal processing equipment, manufacturing tools, casting molten material containers, etc., can solve the problems of large activity space, difficult implementation, and inability to clean ladle residues to achieve high safety and reduce Space, the effect of eliminating the possibility of manual contact with equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details.

[0040]Aiming at the above-mentioned problem that the tilting mechanism itself or during the operation of ladle tilting needs to occupy a large space, it is difficult to realize the large-angle tilting of the steel ladle, resulting in the inability to clean the residue in the steel ladle, etc., it is proposed A ladle tipping device and method are disclosed.

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

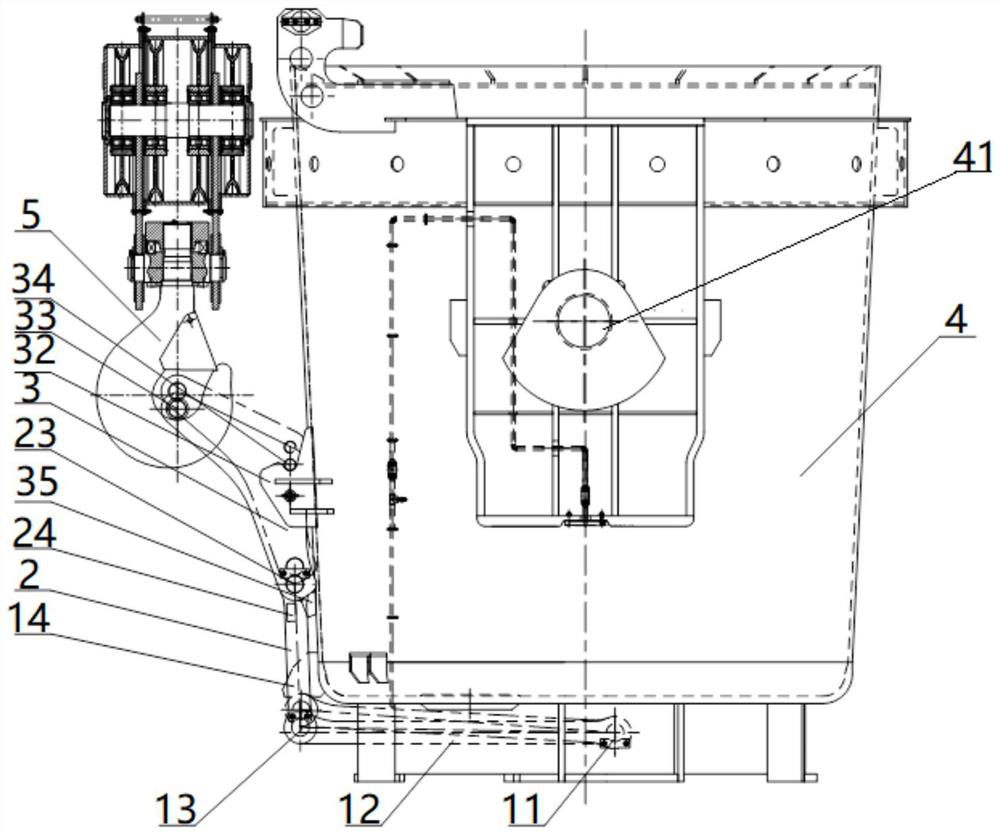

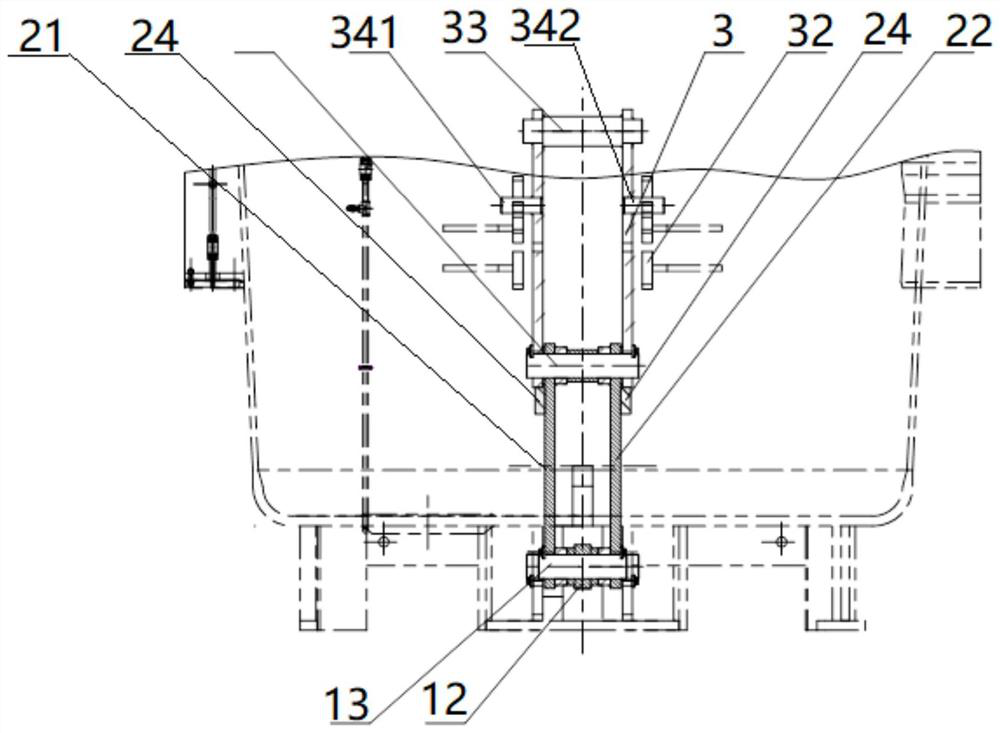

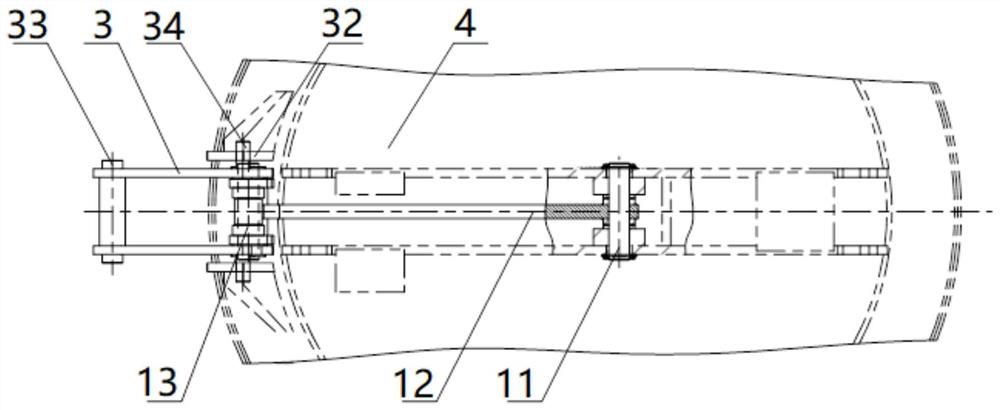

[0042] In order to illustrate the slag storage device provided by the present invention, figure 1 It shows the front view structure of the ladle tipping device according to the embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com