Anti-collision safety device for numerical control turning center

A safety device and turning technology, applied in the field of CNC machine tools, can solve the problems of poor use effect of anti-collision components, and achieve the effect of protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

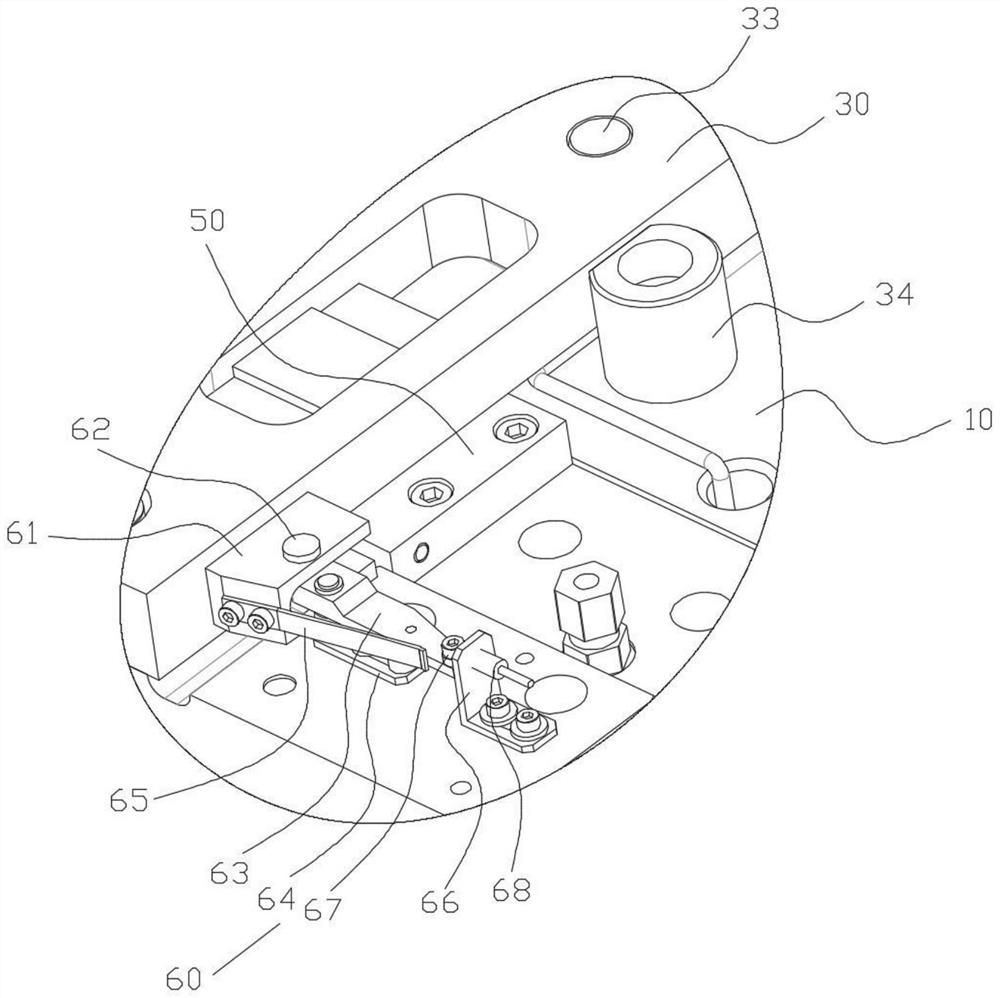

[0060] As an optimized solution of Embodiment 1, the induction component 60 includes

[0061] The coupling block 61 is arranged on the side wall of the transition plate 30;

[0062] The pointer 63 is rotatably connected to the coupling block 61 by pulling out the pin 62;

[0063] The rotating shaft seat 64 is arranged on the slide plate 10, and the pointer 63 is rotationally connected with the rotating shaft seat 64;

[0064] The sensor frame 66 is arranged on the slide plate 10;

[0065] Inductive switch 68 is arranged on the sensor frame 66;

[0066] The detection block 67 is arranged at the end of the pointer 63 , and the detection block 67 is used to detect the position change of the end of the pointer 63 .

[0067] This embodiment is implemented in this way, when there is a collision phenomenon, the position of the transition plate 30 will change; its slight variation is magnified by tens of times through the coupling block 61, the dial pin 62, and the pointer 63, and ...

Embodiment 3

[0069] As an optimized solution of the second embodiment, a spring piece 65 is further provided on the side wall of the coupling block 61 , and the spring piece 65 is in close contact with the pointer 63 .

[0070] This embodiment is implemented in this way, the same spring 65 gives a "pretension" to the pointer 63, so that the pointer 63 cannot swing freely, so as to avoid false alarms

Embodiment 4

[0072] As an optimized solution of the first embodiment, the sliding plate 10 is provided with a stopper 34 facing the side wall of the transition plate 30 .

[0073] This embodiment is implemented in such a way that the transition plate 30 is prevented from infinitely shifting position through the set stopper 34, that is, it plays the role of "dead stop iron". When the transition plate 30 hits it, in principle, it cannot Another position change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com