Pyroelectric ceramic composition, pyroelectric element, and infrared detector

A technology of infrared detector and ceramic composition, which is applied to electric radiation detectors, electrical components, pyroelectric devices, etc., can solve the problems of reduced pyroelectric characteristics, inability to realize infrared detectors, etc., and achieves appropriate reduction in insulation resistance and stable sensor characteristics. , the effect of small fluctuations relative to temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] Next, examples of the present invention will be described in detail.

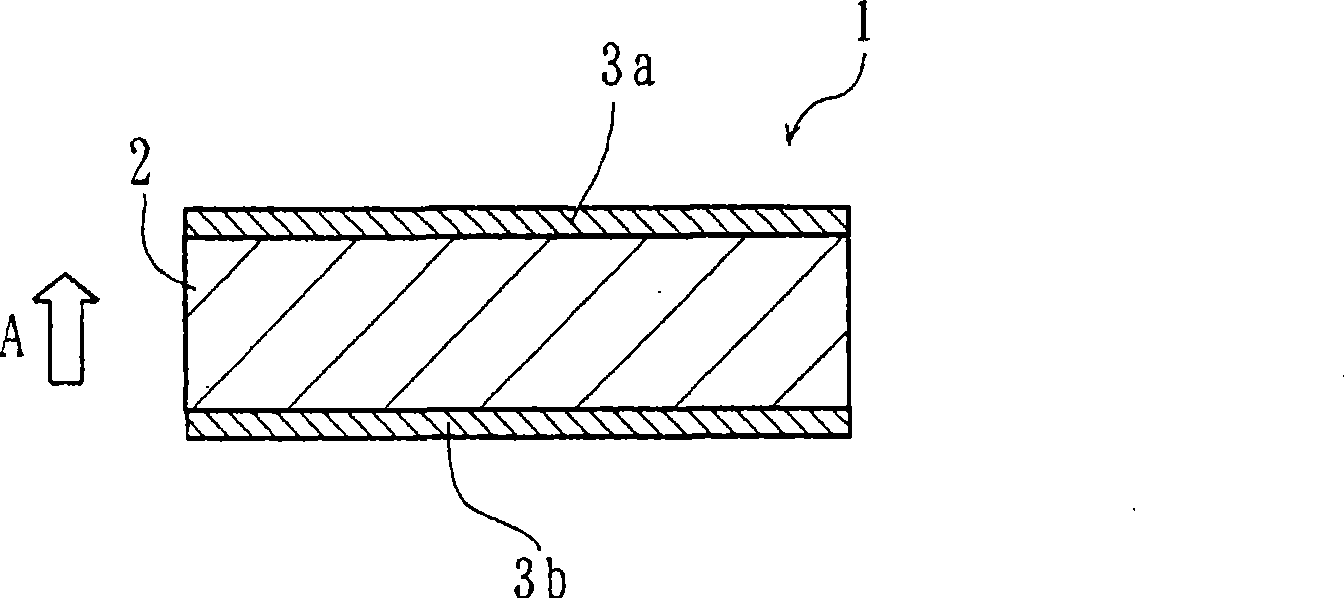

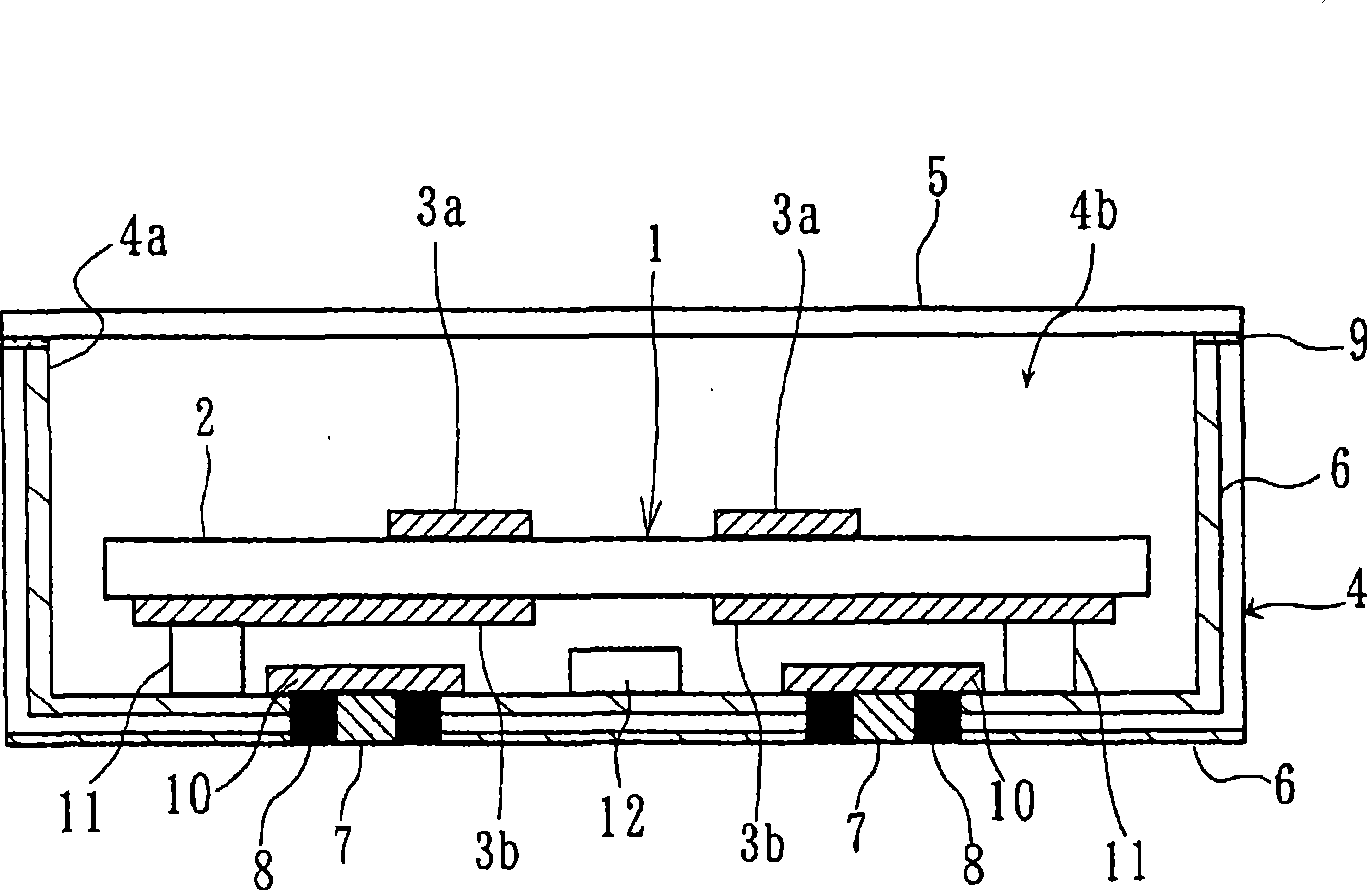

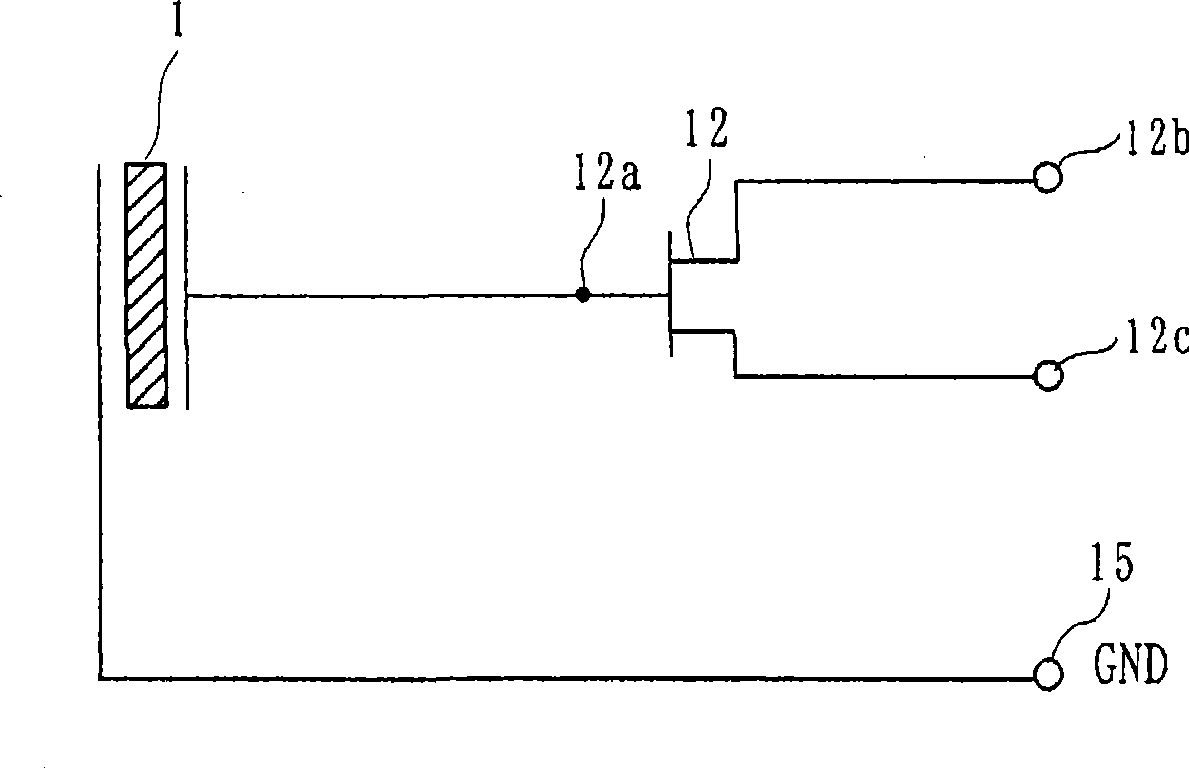

[0094] First, prepare Pb as a ceramic raw material 3 o 4 , CaCO 3 , NiO, Nb 2 o 5 、TiO 2 and MnCO 3 , so that the composition shown in Table 1 was weighed. Next, these ceramic raw materials, PSZ balls and water are put into a ball mill and fully mixed by wet method. The mixed raw material was calcined at a temperature of 900° C. for about 4 hours in an air atmosphere to produce a calcined product. Next, 2.5% by weight of an organic binder was added to the calcined product, wet pulverized by a ball mill for about 16 hours, and dried. Then, use a 40-mesh sieve to granulate the dried roasted product at 8.6×10 7 The obtained powder was press-molded under a pressure of Pa to form a plate-shaped compact having a length of 25 mm, a width of 40 mm, and a thickness of 1.2 mm.

[0095] Next, the above-mentioned plate-shaped molded body was accommodated in a sagger made of alumina, and after performin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com