Polishing machine for metal products and using method of polishing machine

A technology for metal products and polishing machines, applied in the field of mechanical processing, can solve the problems of staying in manual cleaning, and there is no device for stepping shaft burrs, etc., to improve processing efficiency, save tool replacement time, and have good oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

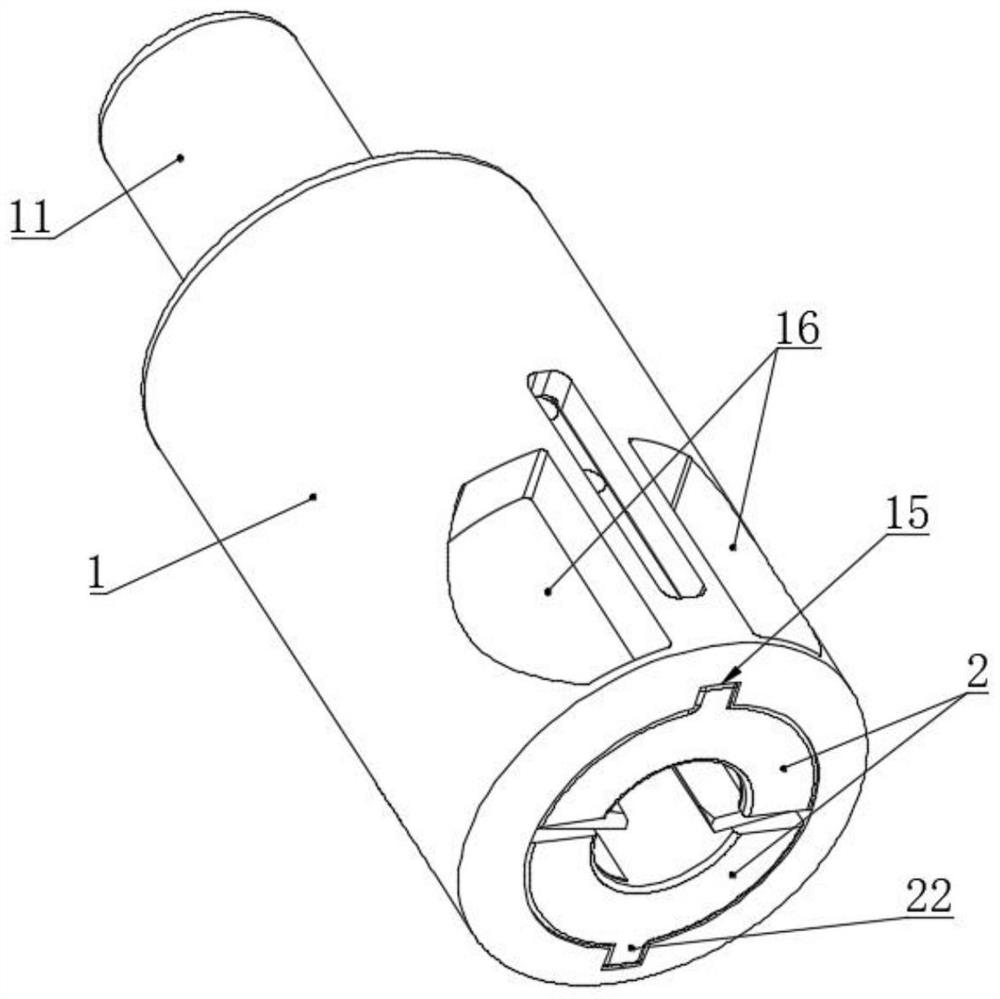

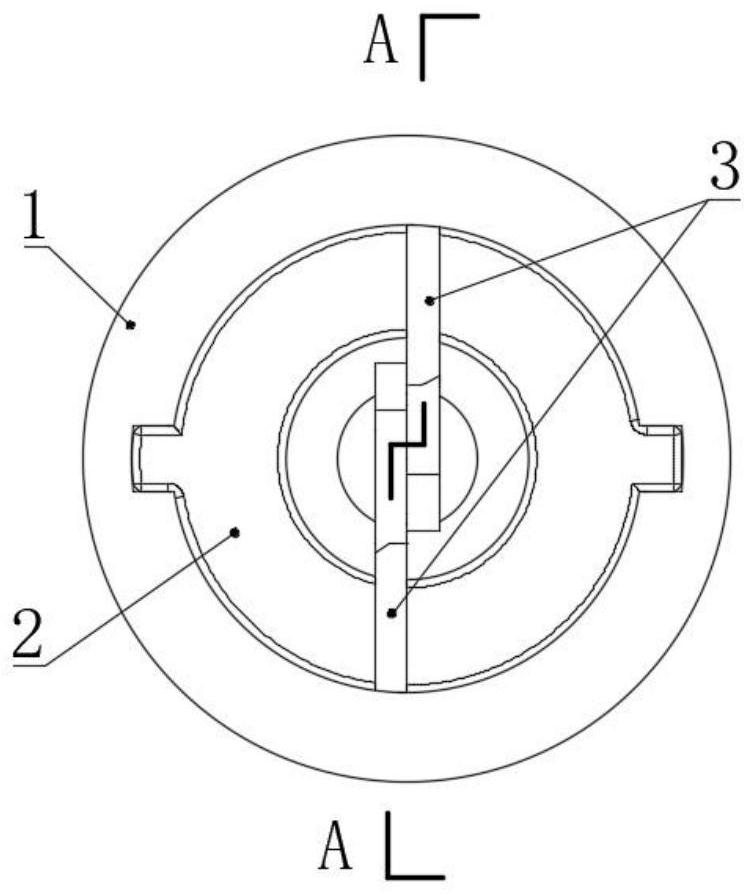

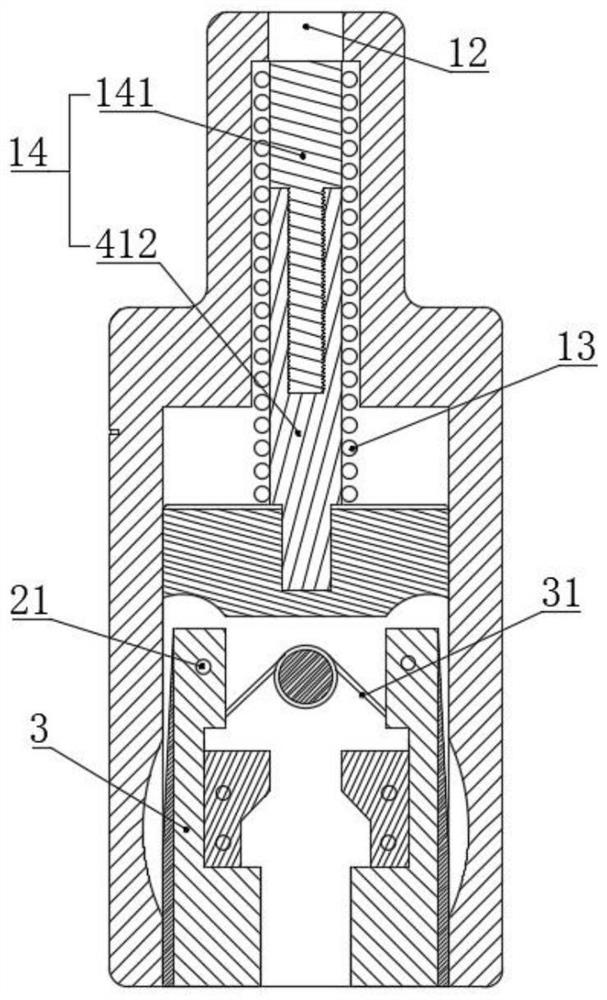

[0049] like Figure 1-7 As shown, a polishing machine for metal products includes a cylindrical knife barrel 1, a cylindrical support frame 2 installed inside the knife barrel 1 and axially slidably connected with it, and an outer shell mounted on the support frame 2. cutter 3;

[0050] The side wall of cutter barrel 1 is provided with through chip guide groove 16, and the upper end of outer cutter 3 is hinged with support frame 2, and the hinged part is hinge seat 21; Acting on the outer cutter 3, the lower end of the outer cutter 3 has a tendency to swing to the outside of the support frame 2.

[0051] The support frame 2 is two semi-cylindrical frame bodies, and the outer cutter 3 and the inner cutter 4 are all arranged between the two frame bodies. This design is convenient for the installation and maintenance of the outer cutter 3 and the inner cutter 4 . Axial slide block 22 is fixed on the outer wall of support frame 2, is provided with the chute 15 that slides with s...

Embodiment 2

[0065] This embodiment is a further improvement of the previous embodiment, such as Figure 1-7 As shown, a polishing machine for metal products includes a cylindrical knife barrel 1, a cylindrical support frame 2 installed inside the knife barrel 1 and axially slidably connected with it, and an outer shell mounted on the support frame 2. cutter 3;

[0066] The side wall of cutter barrel 1 is provided with through chip guide groove 16, and the upper end of outer cutter 3 is hinged with support frame 2, and the hinged part is hinge seat 21; Acting on the outer cutter 3, the lower end of the outer cutter 3 has a tendency to swing to the outside of the support frame 2.

[0067] The support frame 2 is two semi-cylindrical frame bodies, and the outer cutter 3 and the inner cutter 4 are all arranged between the two frame bodies. This design is convenient for the installation and maintenance of the outer cutter 3 and the inner cutter 4 . Axial slide block 22 is fixed on the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com