Hobbing mill for cutting and forming woodwork PET (Polyethylene Terephthalate) plate

A technology of wood products and rolling cutting machines, which is applied in metal processing and other directions, can solve problems affecting subsequent processes, technical cost increase, roller slippage, etc., and achieve the effect of recycling residual materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention will be described clearly and completely, it is clear that the embodiments described are only a part of the embodiment of the present invention, not all embodiments.

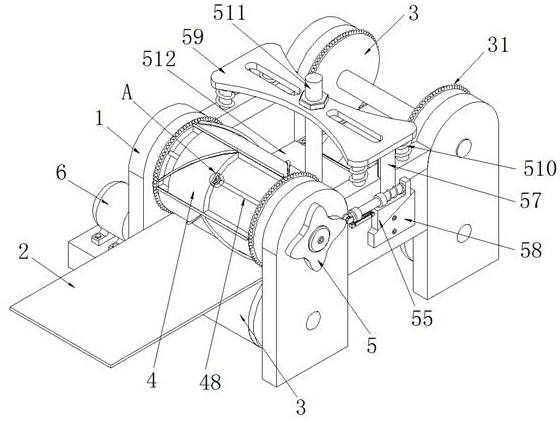

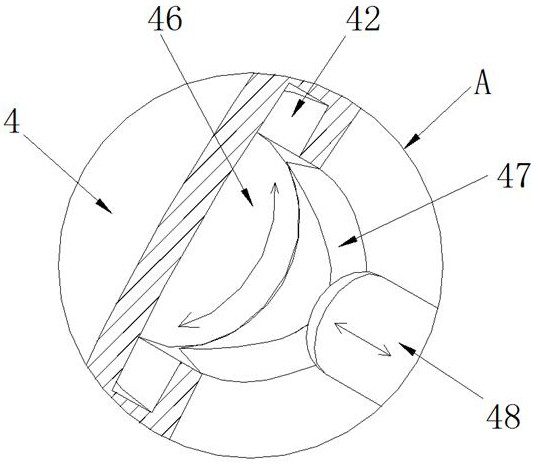

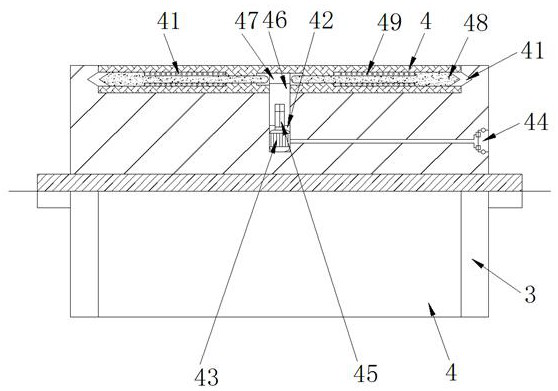

[0048] Reference Figure 1-8, a kind of wood products PET plate cutting molding with a roll cutting machine, including bracket 1 and PET plate 2, the two ends of the bracket 1 are respectively provided for roll cutting feed of the roll cutting mechanism and the export mechanism after roll cutting, the PET plate 2 from the roll cutting mechanism input roll cutting and then from the export mechanism to export the remaining residual material, by setting the export mechanism, can achieve the effect of residual material recovery after the product is stripped from the PET plate 2, and is also synchronized with the roller 3, without additional e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com