Ultra-soft PVC (polyvinyl chloride) environment-friendly granulating and mixing device and production and manufacturing process thereof

A mixing device and ultra-soft technology, which is applied in the field of ultra-soft PVC environmental protection granulation mixing device and its manufacturing process, can solve the problems of slow temperature rise, waste, and inability to post-process, etc., to achieve accurate temperature measurement and improve dispersion Improvement effect of plasticization and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

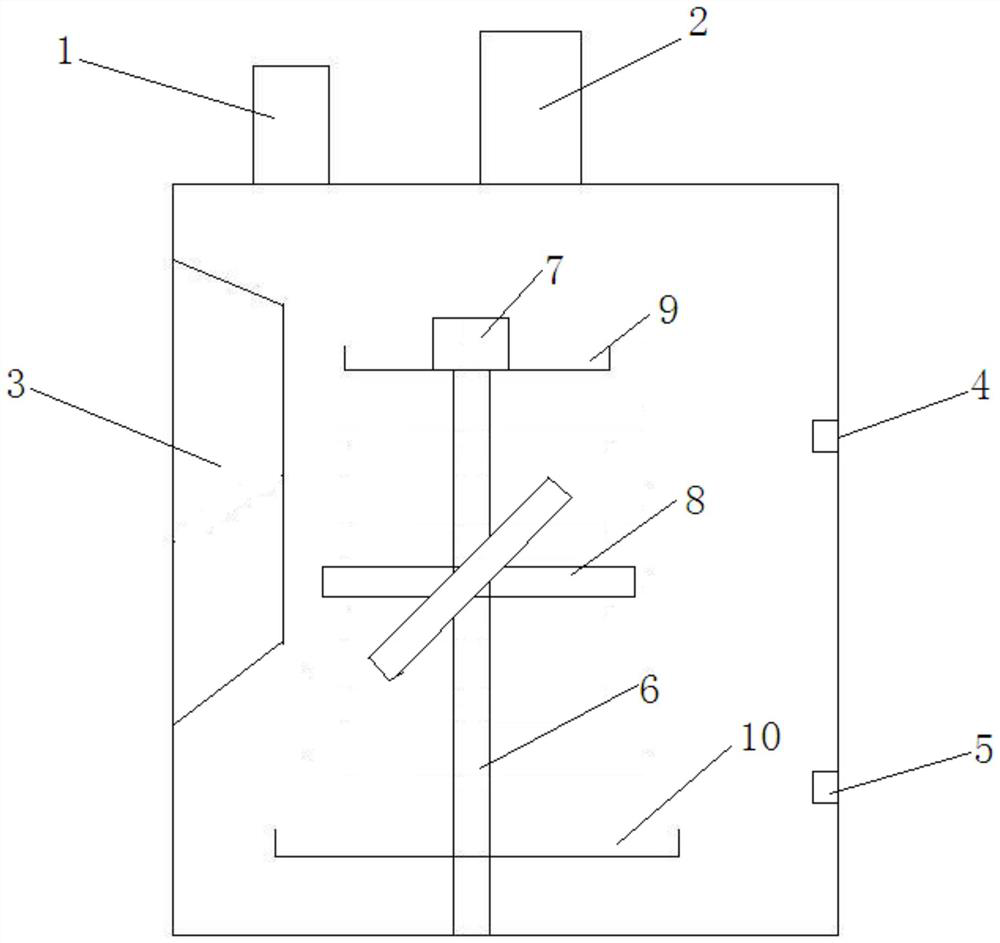

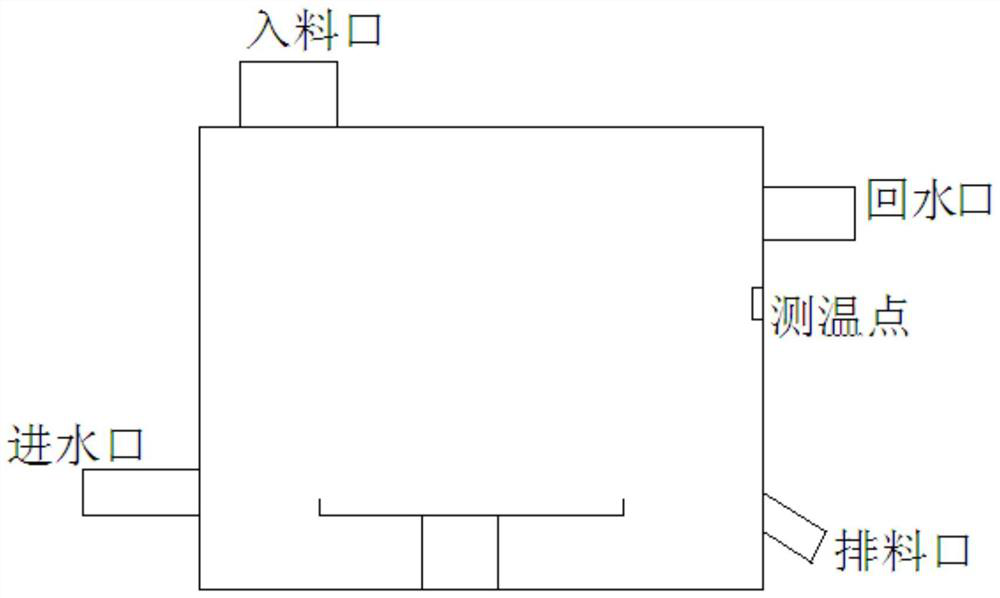

[0035] like figure 2 As shown, a supersoft PVC environment-friendly granulation mixing device includes a mixing device body, and the top of the mixing device body is provided with a PVC powder discharge port 1 and a plasticizer liquid discharge port 2; A splitter plate 3 is installed on the inner side wall of the mixing device, and the length of the splitter plate 3 is lengthened on the original basis to increase shear force and increase plasticization; the splitter plate 3 is located at Below the PVC powder discharge port 1, a first temperature measuring point 4 and a second temperature measuring point 5 are installed on the other side wall inside the mixing device, and the first temperature measuring point 4 is located on the inner wall The upper part, the second temperature measuring point 5 is located at the bottom of the inner wall; one temperature measuring point is added on the original basis, and the temperature measurement is more accurate; the inner center of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com