Box section type fuselage assembly process based on force-position coupling

An assembly process and box-section technology, which is applied in the field of box-section fuselage assembly technology, can solve problems such as failure to meet installation requirements, large assembly stress, and bulky tooling, meet assembly coordination requirements, and reduce ear springback , Improve the effect of service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

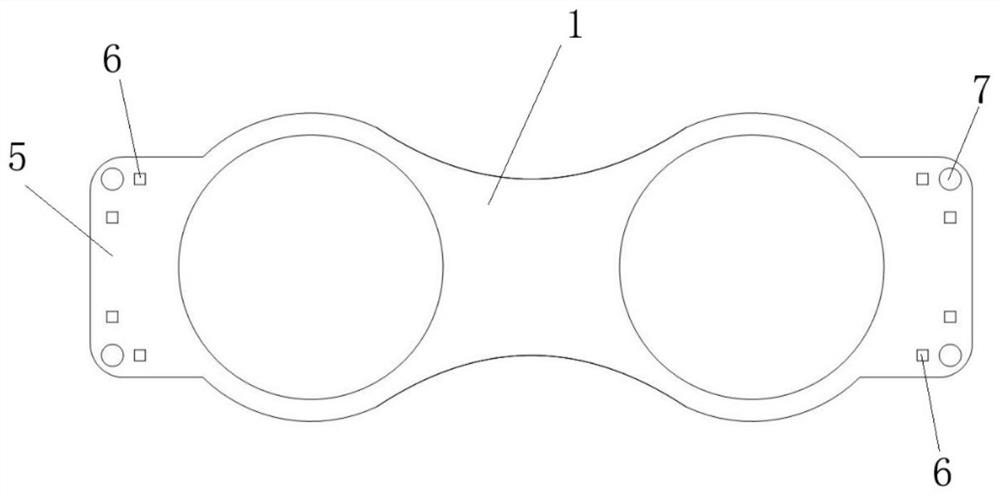

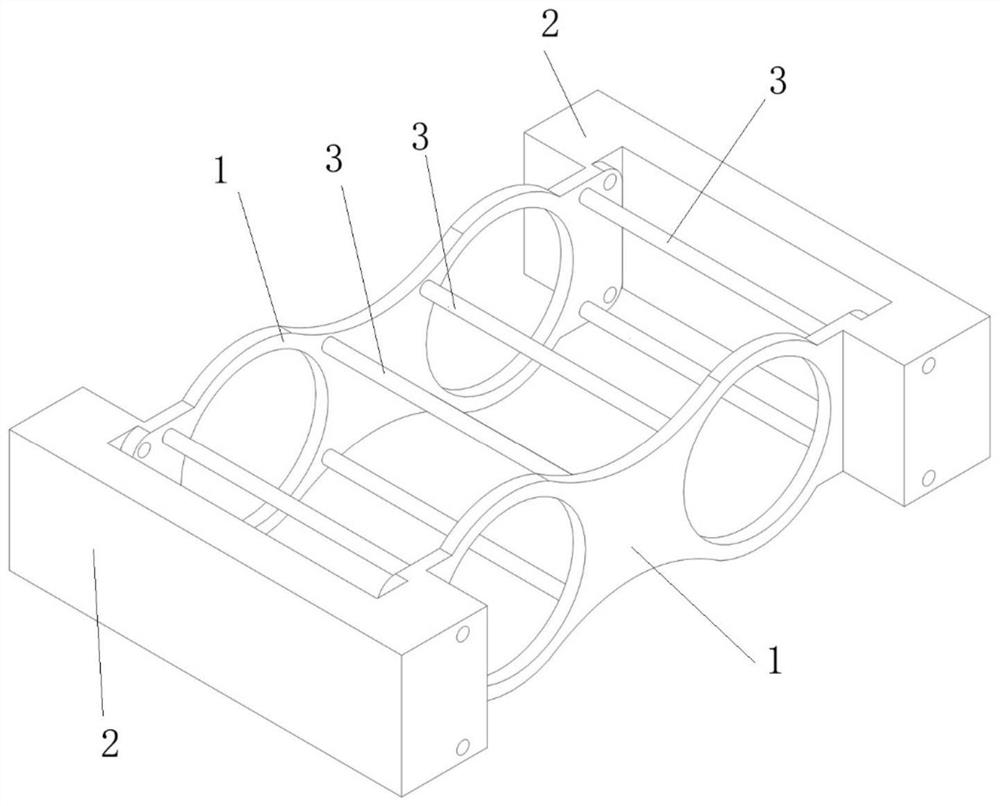

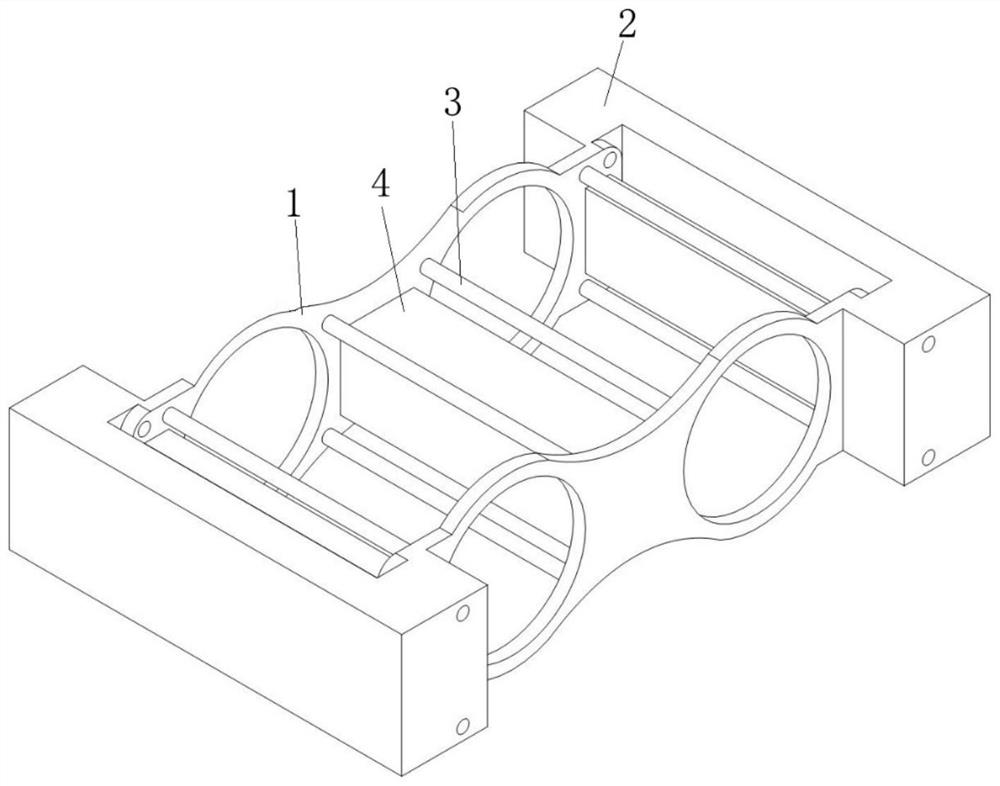

[0023] This embodiment relates to a box-section fuselage assembly process based on force-position coupling, such as Figure 1-Figure 5 shown, including the following steps:

[0024] Step 1, such as figure 1 As shown, a pressure sensor 6 is provided on the lug 5 of the wall panel 1, and two wall panels 6 are connected together by a plurality of telescopic struts 3 to form a temporary rigid structure. Multiple length-adjustable struts realize the connection between the two wall panels to be assembled, and at the same time adjust the position and posture of the two wall panels and the distance between the mating surface of the corresponding tooling locator through the spread distance of different strut positions.

[0025] Preferably, the strut 3 can be arranged around the area where the assembly stress is relatively concentrated according to the actual space position, such as around the matching area between the ear piece 5 of the wall panel and the tool positioner 2, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com