Energy-saving concrete pier maintenance device

A concrete and energy-saving technology, applied in bridges, bridge construction, bridge maintenance, etc., can solve problems such as low operating efficiency, affecting project quality, and heavy workload, and achieve the effect of saving manpower and water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

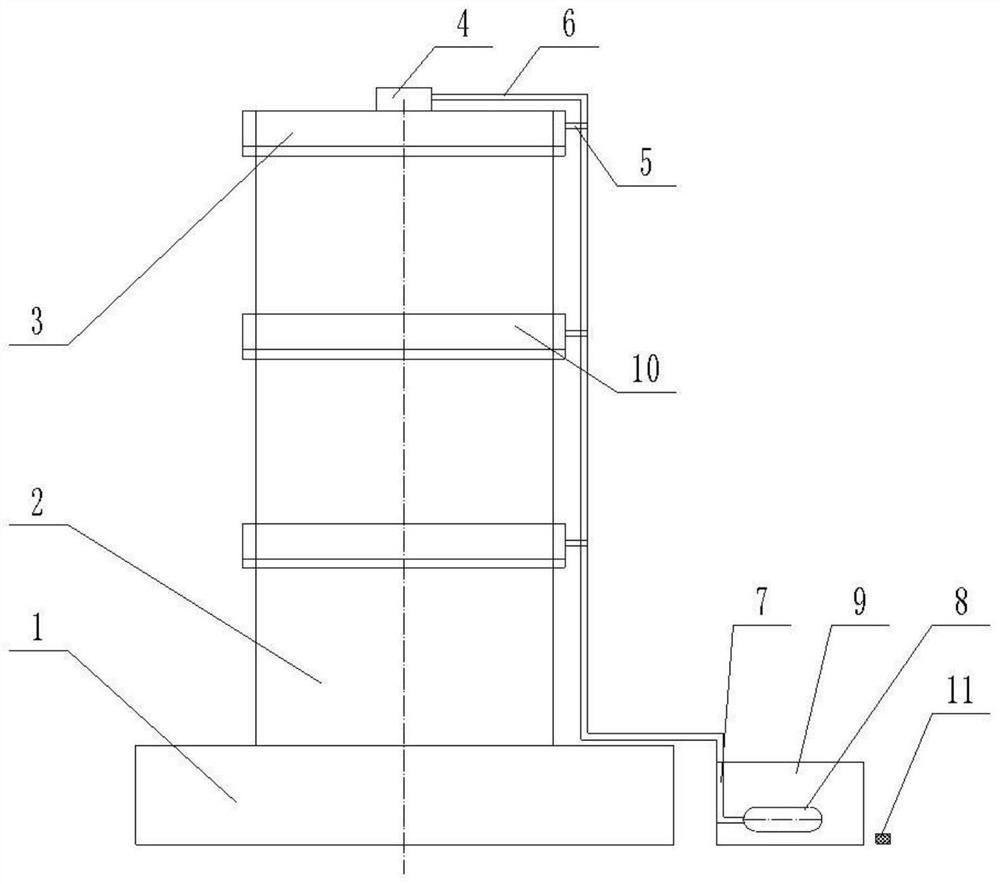

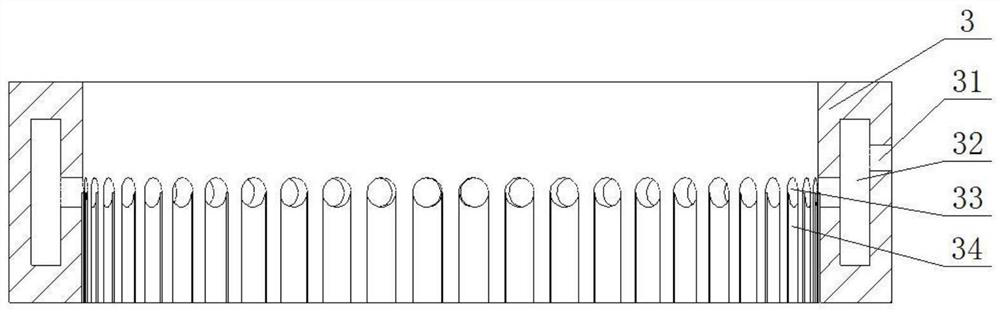

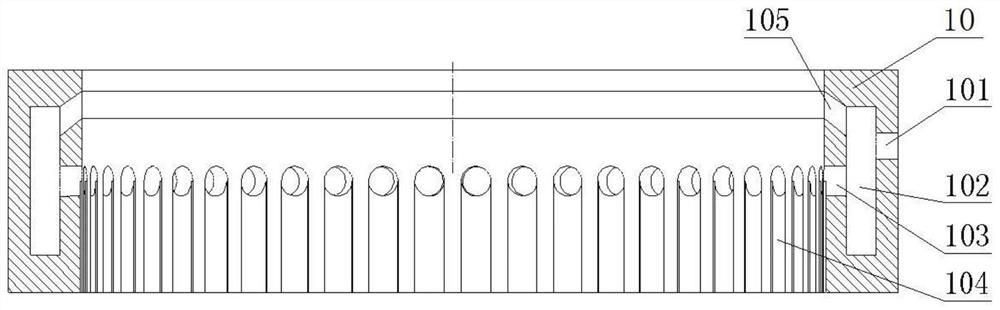

[0018] Such as figure 1 , an energy-saving concrete bridge pier maintenance device, including side sprinkler device 3, top sprinkler device 4, side water delivery pipe 5, top water delivery pipe 6, main water delivery pipe 7, water pump 8, water supply tank 9, side shower Device 10, time relay 11. 1 is a concrete platform, 2 is a concrete pier, and the concrete pier 2 is set on the concrete platform 1. The water supply system is composed of a water supply pool 9, a water pump 8, a side water delivery pipe 5, a top water delivery pipe 6, and a main water delivery pipe 7; 5. The water delivery pipes 6 on the top part are all connected with the main water delivery pipe 7, the water delivery pipes 6 on the top part supply water to the top sprinkler device 4, the water supply pipes 5 on the side supply water to the spray device 3 on the side, the water pump 8, the water delivery pipe 5 on the side, The water delivery pipes 6 at the top are all provided with a time relay 11, throug...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap