Check gate with high-pressure silt flushing function

A technology for controlling gates and scouring. It is applied in mechanically driven excavators/dredgers, marine engineering, construction, etc. It can solve the problems of increasing the difficulty, inconvenience, and corrosion of gates, so as to ensure the efficiency of dredging and improve the efficiency of the gate. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

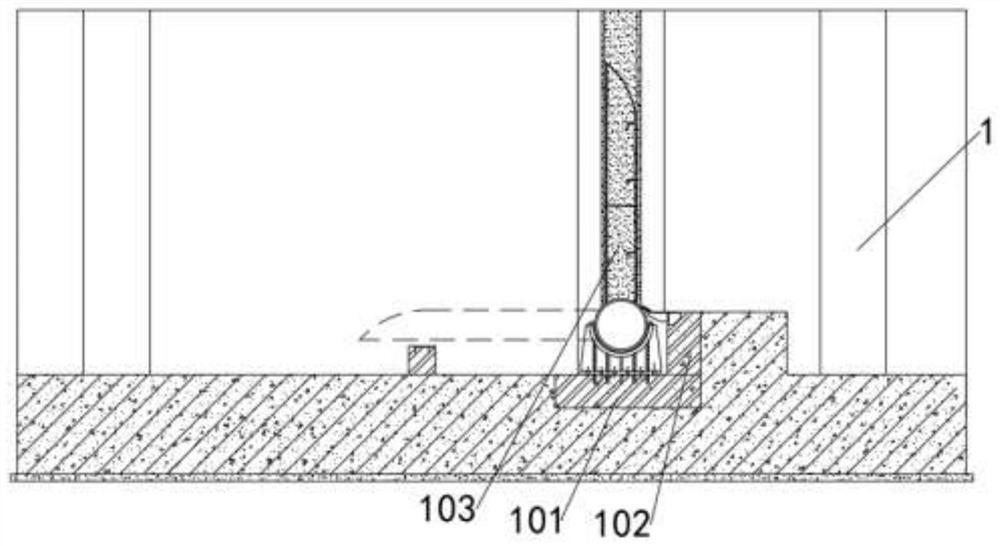

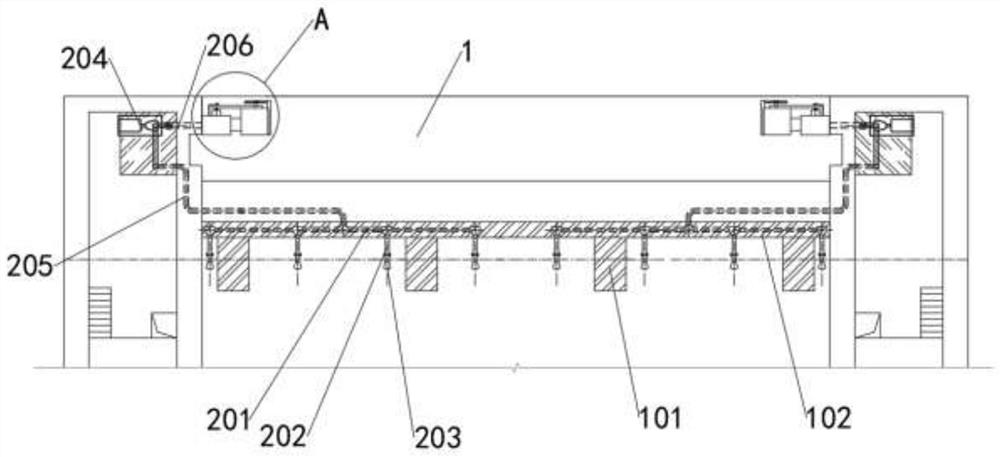

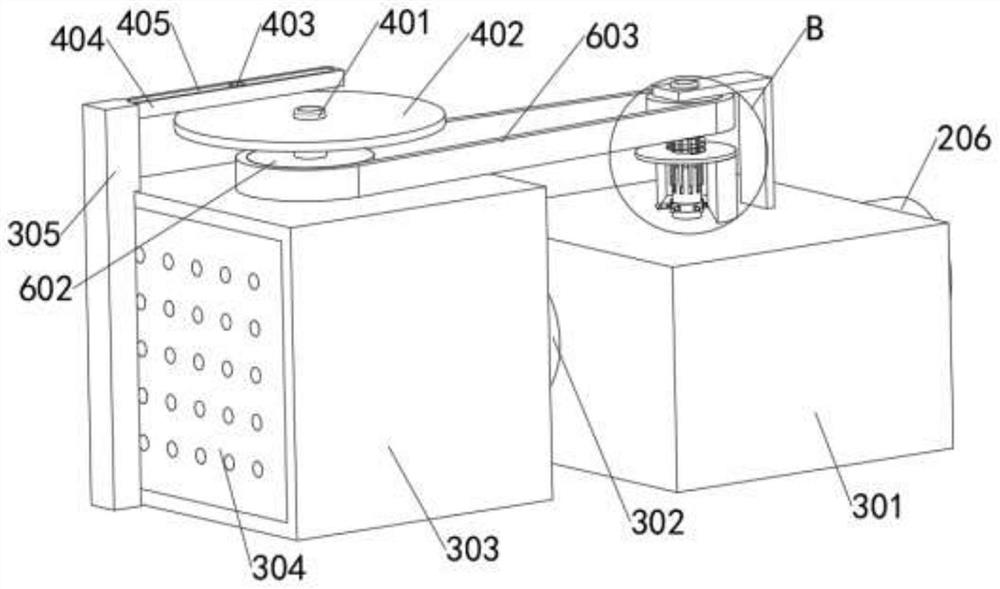

[0028] Such as Figure 1-6 As shown, this embodiment provides a control gate with high-pressure scouring and silting function, including a mounting plate 101 and a baffle plate 102 arranged at the bottom of the gate body 1, and a gate 103 is arranged on the mounting plate 101, and a gate 103 is arranged in the gate body 1. There is a high-pressure scouring mechanism, which can pump water through the pump body 204 to carry out high-pressure scouring of the sludge at the bottom of the gate body 1 to ensure the efficiency and effect of desilting. Automatic cleaning of foreign matter to avoid its blockage and ensure the effect of high-pressure silting;

[0029] The high-pressure silting mechanism includes two symmetrically arranged first steel pipes 201 pre-buried in the baffle 102, and the side walls of each first steel pipe 201 are fixedly connected with a plurality of outlet pipes 202 arranged in arrays, and the other ends of the outlet pipes 202 run through The side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com