Stop valve capable of finely adjusting flow

A cut-off valve and flow rate technology, applied in the field of cut-off valves, can solve the problems of cut-off valves that cannot be fine-tuned and throttled stably, and achieve the effects of reducing flow rate, good fine-tuning control, and increasing the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

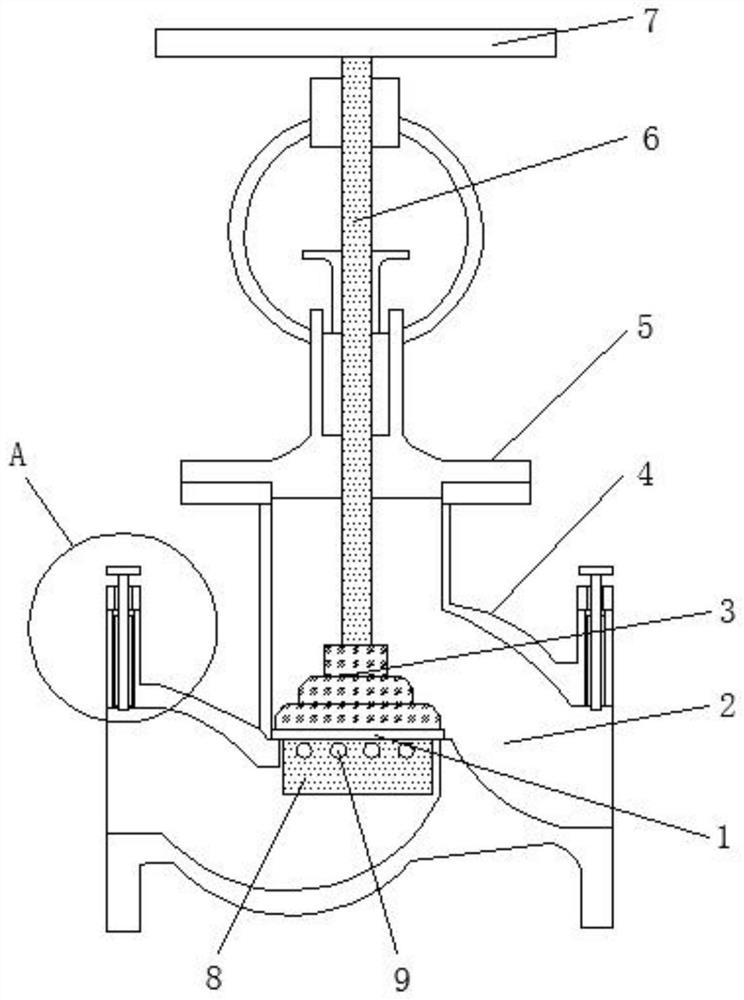

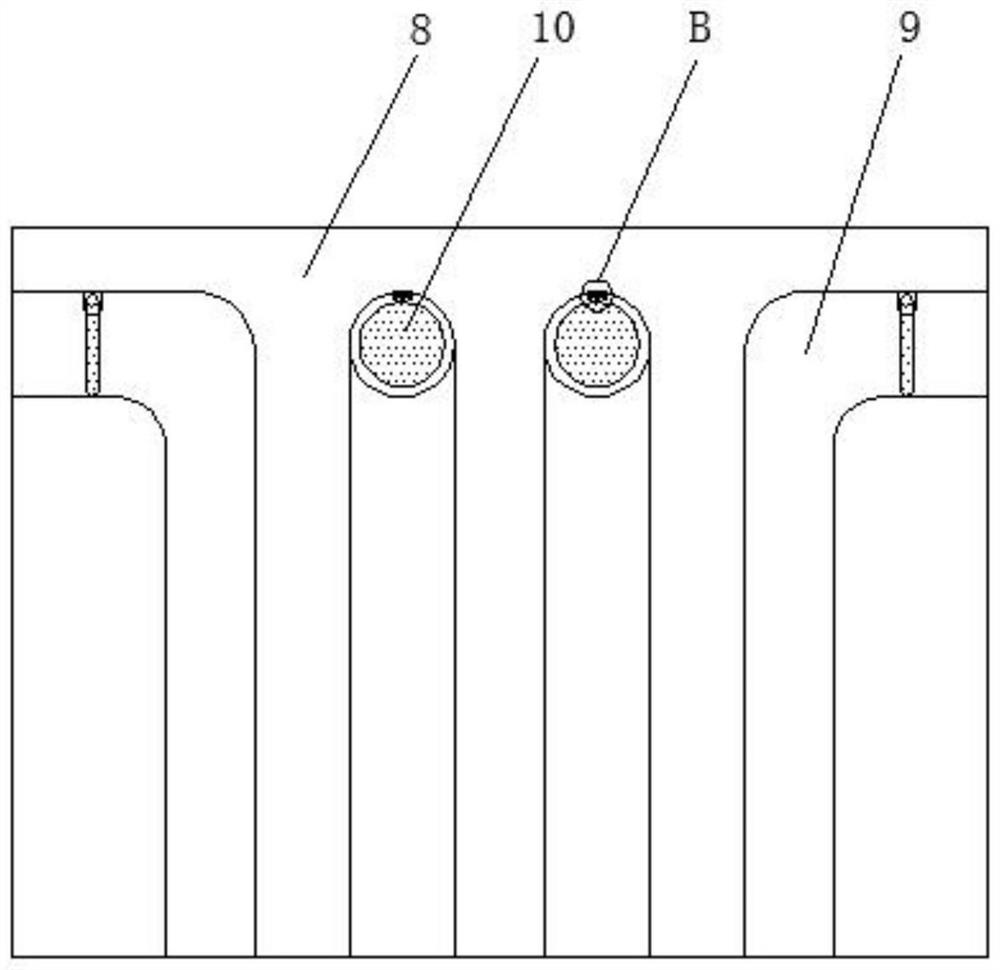

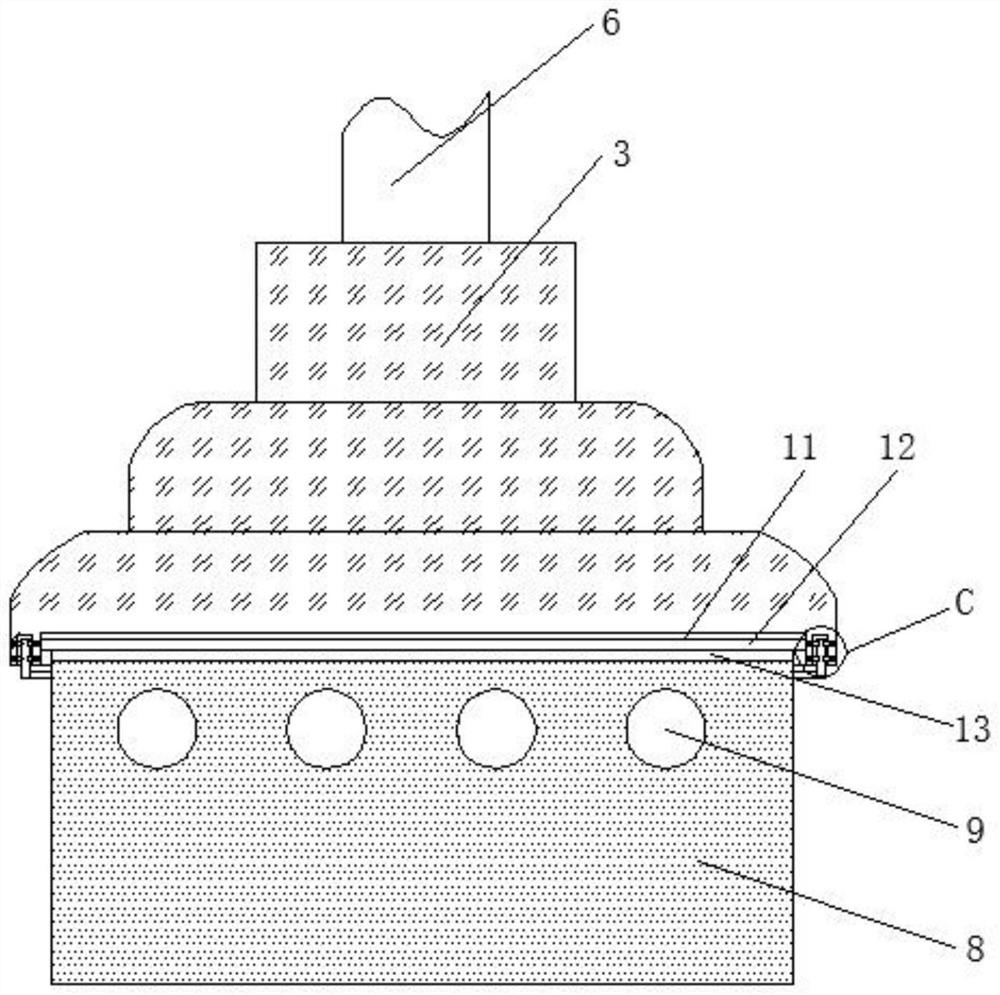

[0026] Embodiment one, with reference to figure 1 , 2 , 3 and 7: A cut-off valve capable of fine-tuning the flow rate, including a valve body 4, a valve hole 2 is opened inside the valve body 4, a valve cover 5 is fixed on the top of the valve body 4, and the inner surface wall of the valve hole 2 slides A valve stem 6 is embedded, and the top end of the valve stem 6 extends to the top of the valve cover 5, the top end of the valve stem 6 is provided with a hand wheel 7, the bottom of the valve stem 6 is provided with a valve disc 3, and the center of the valve hole 2 The top of the seat is fixed with a sealing seat cushion 1, and the top of the sealing seat cushion 1 is closely attached to the bottom edge of the valve disc 3, which is convenient for blocking the valve hole 2. There is a notch at the center of the bottom of the valve disc 3, and the notch The inner surface wall of the cylinder 8 is fixed with a first magnet layer 11, the bottom of the first magnet layer 11 is...

Embodiment 2

[0027] Embodiment two, refer to Figure 8: The bottom of the disc 3 is provided with four circular holes 25 equidistant along the circumferential direction, and the inner surface walls of the four circular holes 25 are all engaged with L-shaped rods 34, and the inner surface walls on both sides of the circular holes 25 are close to the center. Each side is provided with a square mouth 28, and the inner surface walls on both sides of the square mouth 28 are provided with chute 27 along the horizontal direction. There are sliders 32, and the sliders 32 slide left and right on the inner surface wall of the chute 27. There are multiple sliders 32, and they are divided into multiple groups. A fixed plate 31 is welded between each group of two sliders 32. One side outer surface center of fixed plate 31 is welded with compression spring 30, and one end of compression spring 30 is welded with the inner surface wall of square mouth 28, and the outer surface of compression spring 30 is ...

Embodiment 3

[0028] Embodiment three, refer to Figure 4 , 5 And 6: the top of the valve body 4 is welded with a fixed block 35 near the edges of both sides, the fixed block 35 is provided with a threaded hole 36 along the vertical direction, the inner surface wall of the threaded hole 36 is threadedly connected with a screw rod 14, and the screw rod 14 extends to the outside of the fixed block 35, and the screw rod 14 can be moved up and down by rotating the screw rod 14 on the inner surface wall of the threaded hole 36. The inside of the valve body 4 is located at the bottom of the fixed block 35 and opened vertically. There is a receiving hole 37, the top of the receiving hole 37 communicates with the bottom of the threaded hole 36, the outer surfaces of both sides of the screw mandrel 14 are welded with U-shaped long blocks 15, and the inner surface walls of both sides of the U-shaped long block 15 are along the vertical direction. Two rotating rods 17 are welded, the outer surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com