Drainage waste heat utilization system of power station boiler

A power plant boiler and water-repellent technology, which is applied in the direction of boiler cleaning equipment, etc., can solve the problems of energy waste and ineffective utilization of calorific value, and achieve the effect of improving the effect of waste heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-5 The application is described in further detail.

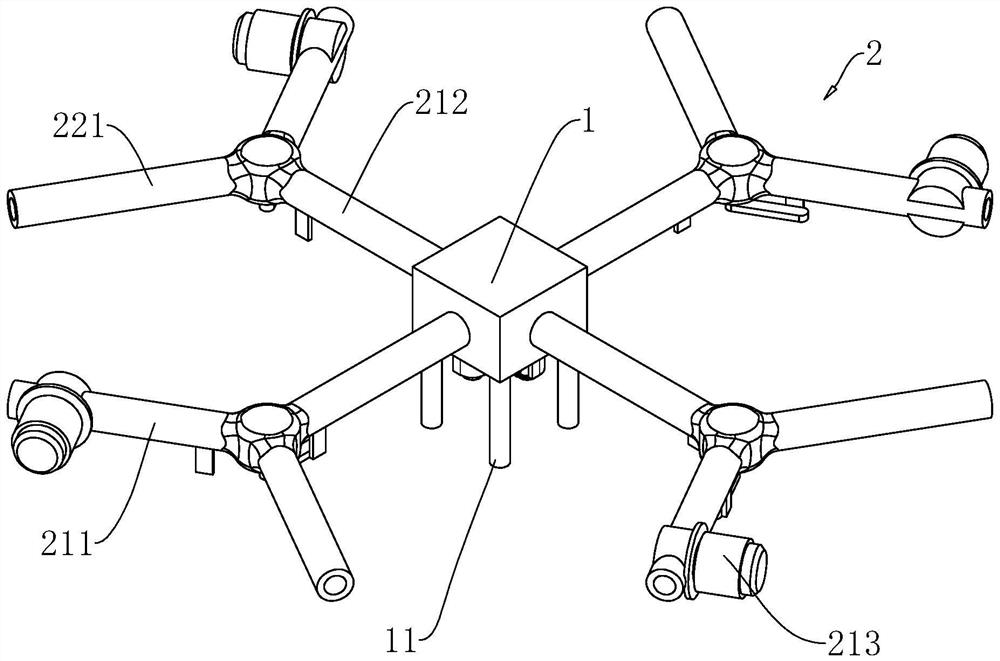

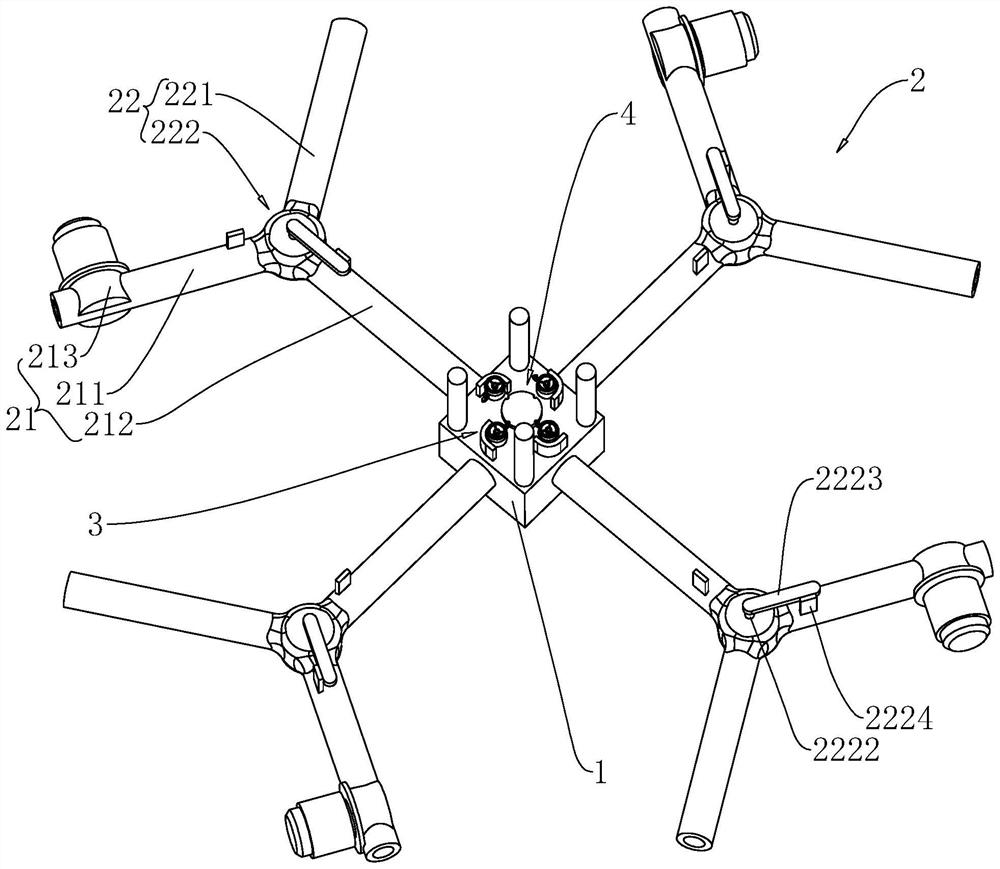

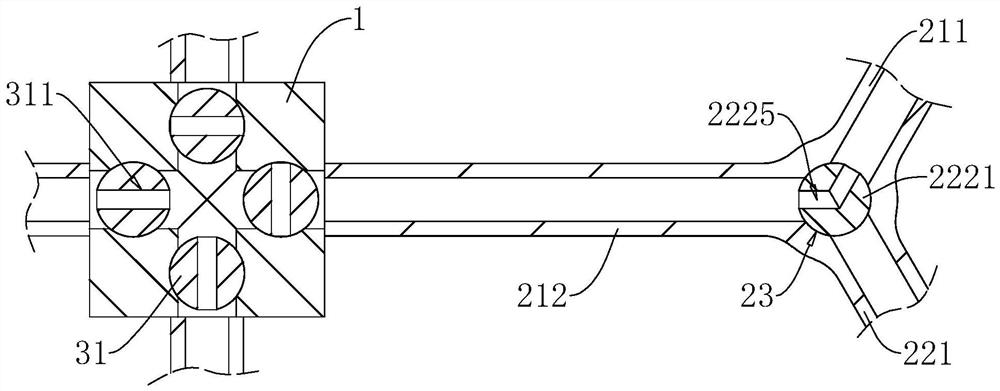

[0042] The embodiment of the present application discloses a drainage waste heat utilization system of a utility boiler. refer to figure 1 , figure 2 , The drainage waste heat utilization system of the power plant boiler includes a water collection tank 1, four sets of water outlet and return devices 2, four sets of opening and closing mechanisms 3 and a locking mechanism 4, and four support columns 11 are fixed on the bottom wall of the water collection tank 1.

[0043] refer to figure 2 , image 3 The water outlet and return device 2 includes a water outlet mechanism 21 and a water return mechanism 22 , the water outlet mechanism 21 includes a water outlet pipe 211 , a water collection pipe 212 and a drain pump 213 , and the water return mechanism 22 includes a water inlet pipe 221 and a water blocking assembly 222 . One end of the water outlet pipe 211 is used to be fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com