Patents

Literature

43results about How to "Improve waste heat utilization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

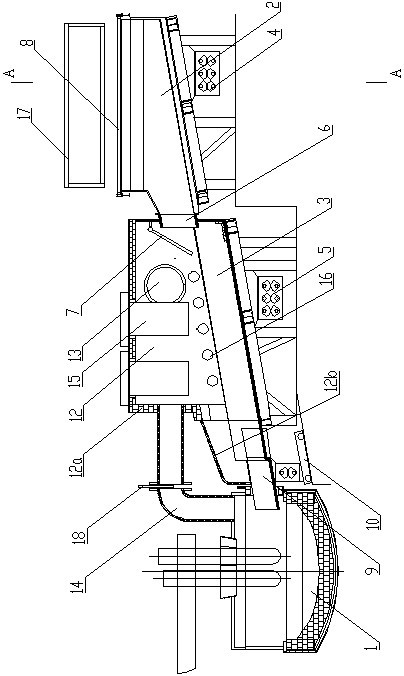

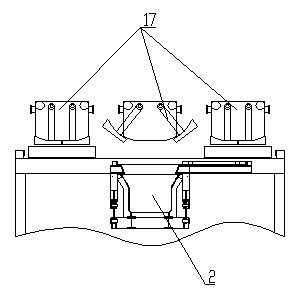

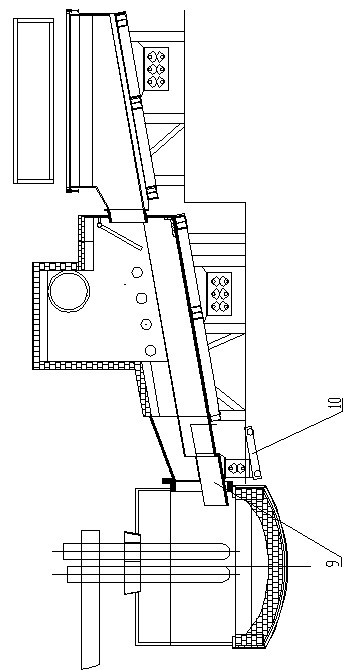

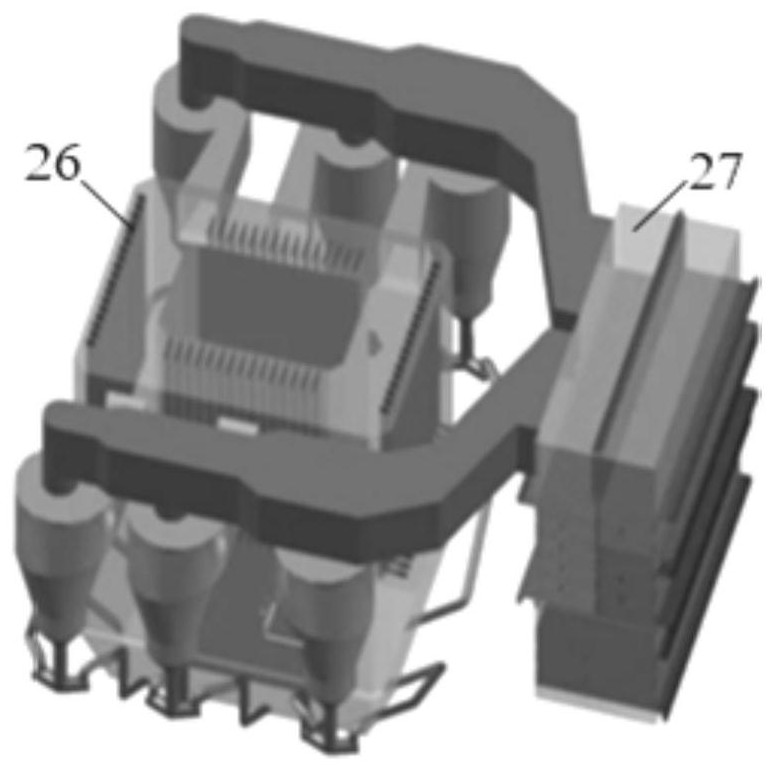

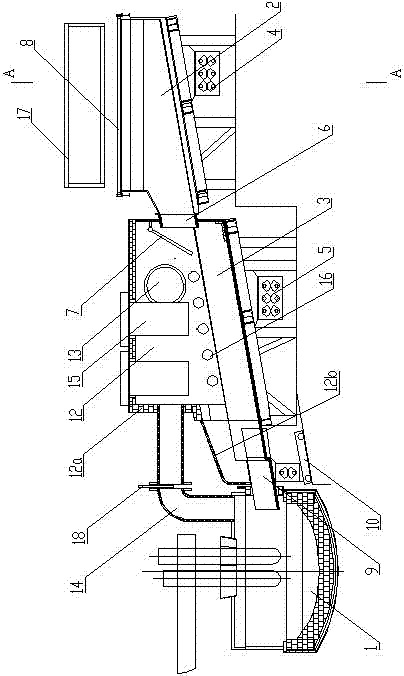

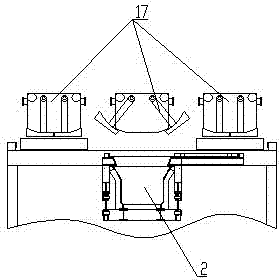

Differential motion airtight feeding electric furnace smelting device and feeding method thereof

ActiveCN102181601AShorten the lengthIncrease the feeding speedCharge manipulationElectric furnaceEngineeringHeat losses

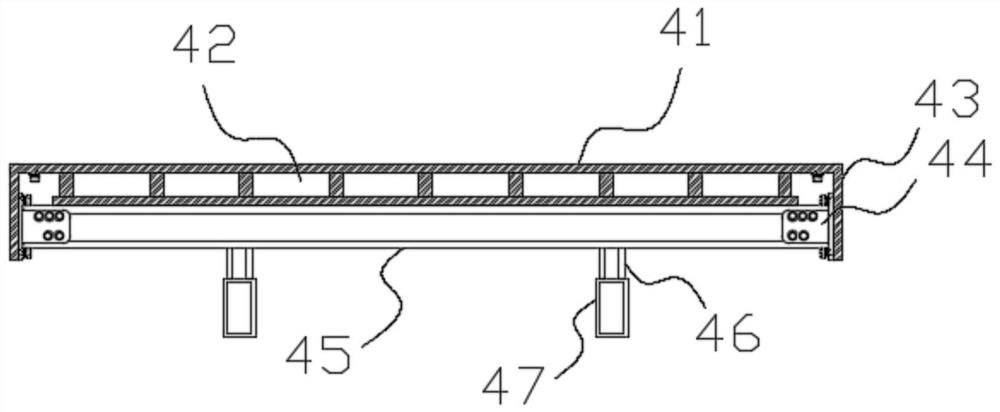

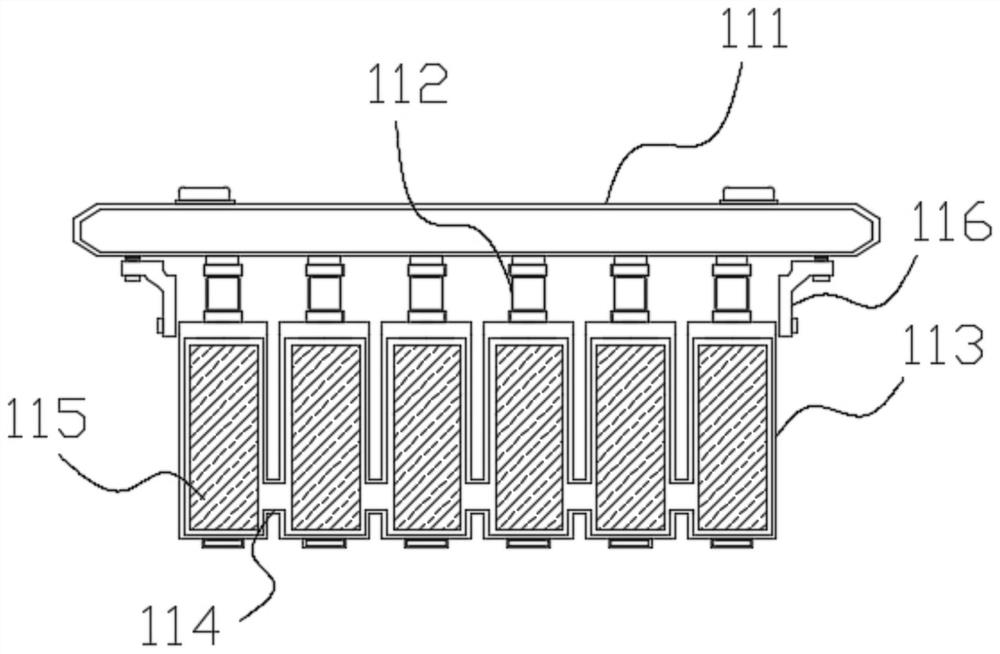

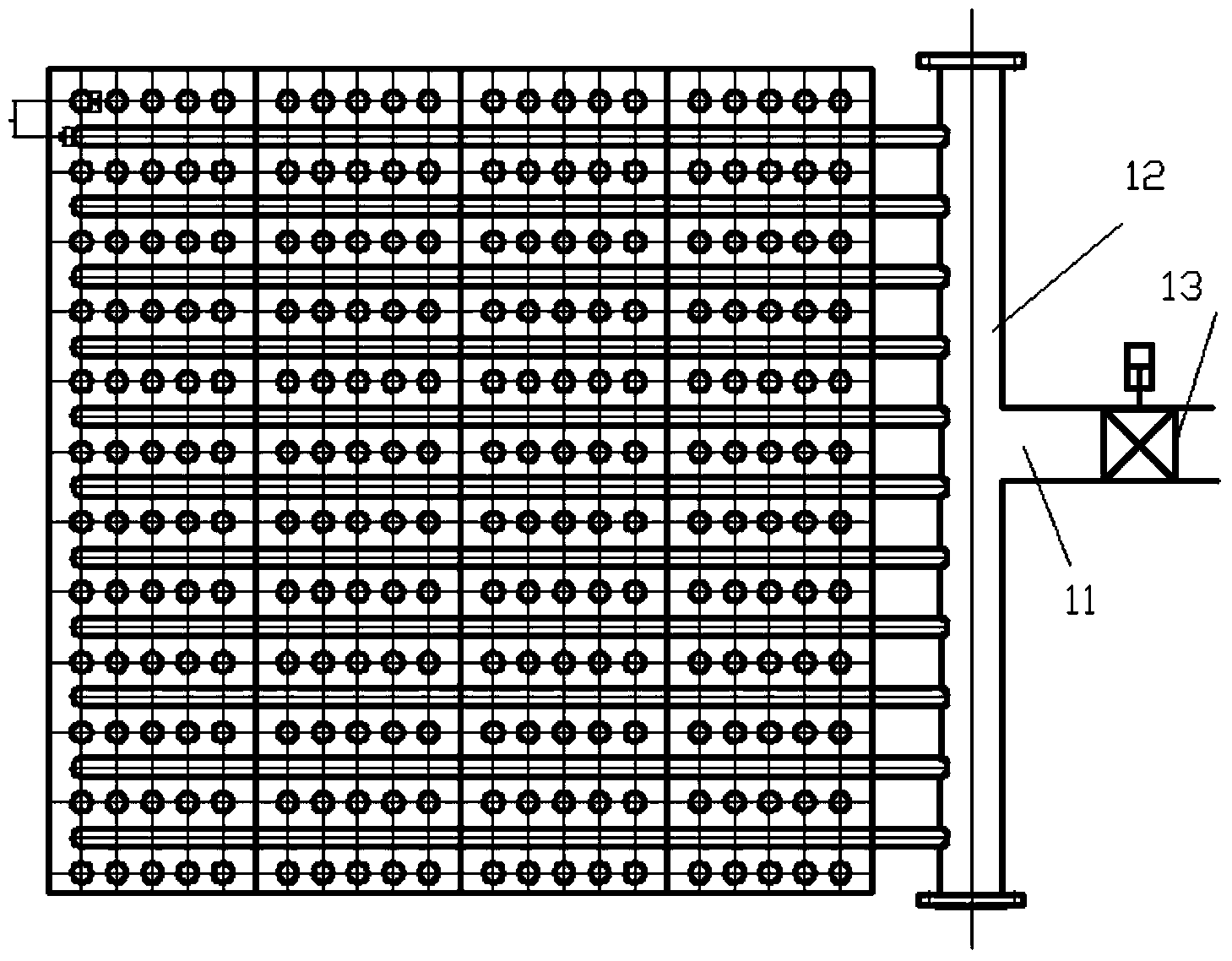

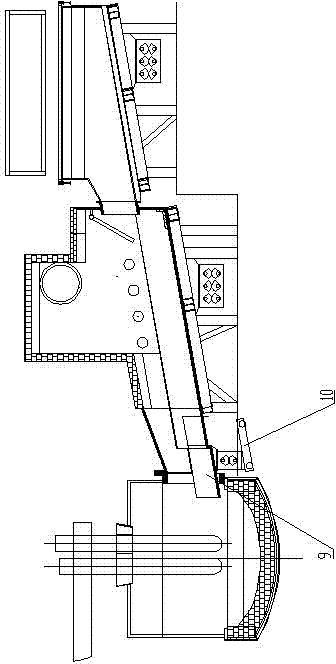

The invention discloses a differential motion airtight feeding electric furnace smelting device and a feeding method thereof. The device comprises an electric furnace and a charging device, wherein the charging device comprises a cold receiving conveying trough and a heat conveying trough; the lower sides of the cold receiving conveying trough and the heat conveying trough are provided with an independently-controlled excitation device respectively; the outlet of the cold receiving conveying trough is provided with a conveying throat opening which is extended into the heat conveying trough; and the distance between the conveying throat opening and the bottom of the heat conveying trough is greater than or equal to the depth of the heat conveying trough. By the feeding method, shock excitation at different frequencies is applied to the two conveying troughs to realize the differential motion conveying of raw materials, so that a thicker material layer can be laid on the cold receiving conveying trough, and the material loading speed is increased; simultaneously, a shorter cold receiving conveying trough and a shorter material-conveying bottom elongated slot can be designed, so that the device and the method make project implementation convenient. In addition, due to the adoption of the throat opening and a sealed door structure, the possibility of material blocking and the air leakage rate are greatly reduced, and the device has low heat loss and a good dedusting effect, and is high-efficient, energy-saving and environment-friendly during smelting.

Owner:CISDI ENG CO LTD

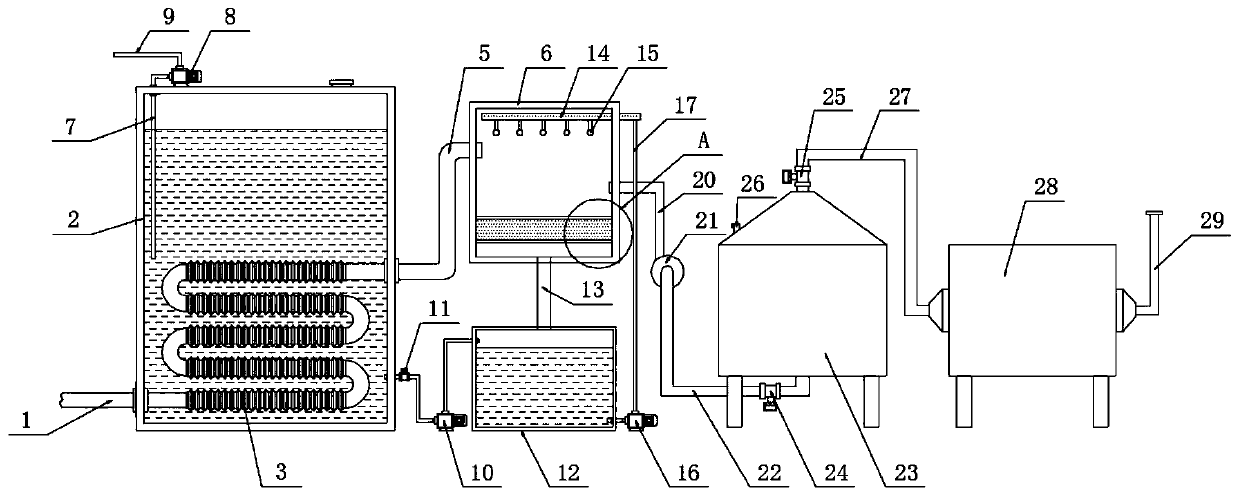

Exhaust gas absorption device for aluminum alloy die casting product production

InactiveCN110327742AEfficient use ofImprove waste heat utilization effectGas treatmentLighting and heating apparatusWater storage tankAdhesion strength

The invention discloses an exhaust gas absorption device for aluminum alloy die casting product production, and concretely relates to the field of exhaust gas treatment. The device comprises a gas inlet tube, one end of the gas inlet tube is connected to the bottom of a water storage tank, a heat exchange tube is arranged at the end part, corresponding to the gas inlet tube, in the water storage tank, one end of the heat exchange tube is connected to the outer sidewall of the middle part of the water storage tank and is connected with a first gas delivery tube, one end of the first gas delivery tube is connected to the top of a spray tank, the front surface of the water storage tank is provided with a control switch, a water drawing tube is inserted into the water storage tank, one end ofthe water drawing tube is connected to the water inlet end of a first water pump, the water outlet end of the first water pump is connected with a first water outlet tube, and a second water pump is arranged at one side of the bottom of the water storage tank. The device improves the waste heat utilization effect of exhaust gas during use, and a part of the heated water is used for circulating spray treatment to improve the adhesion strength of harmful substances and particulate matters in the exhaust gas, so the purification effect on the exhaust gas is improved.

Owner:巢湖云海镁业有限公司

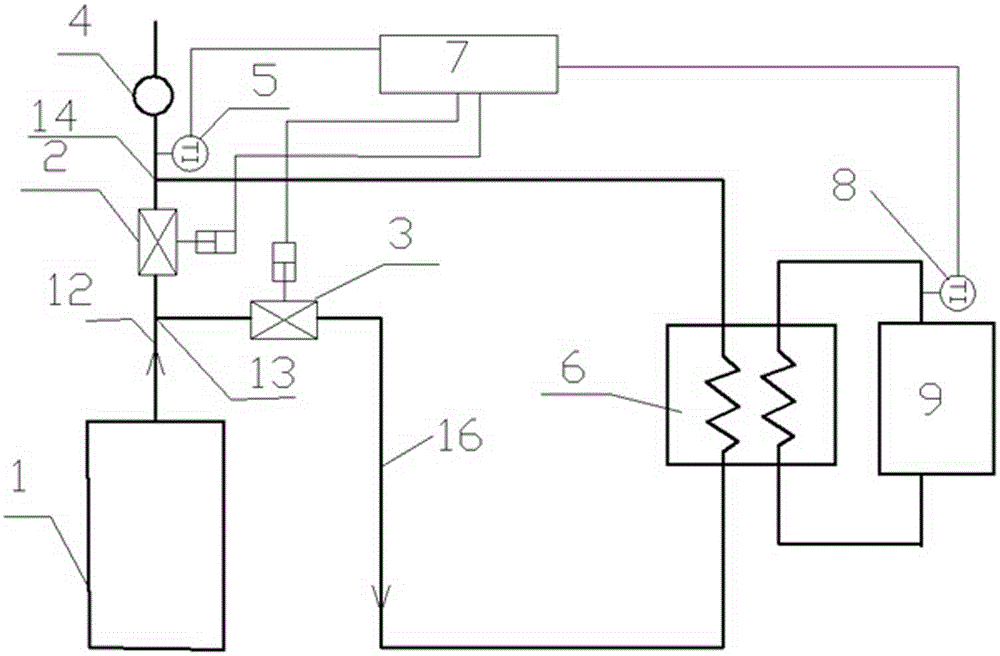

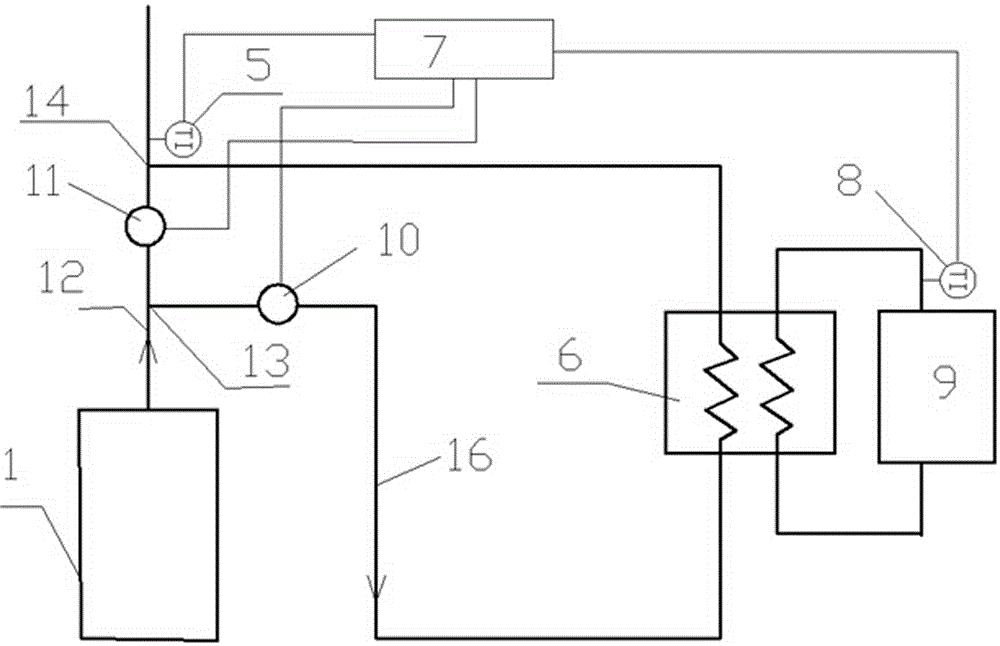

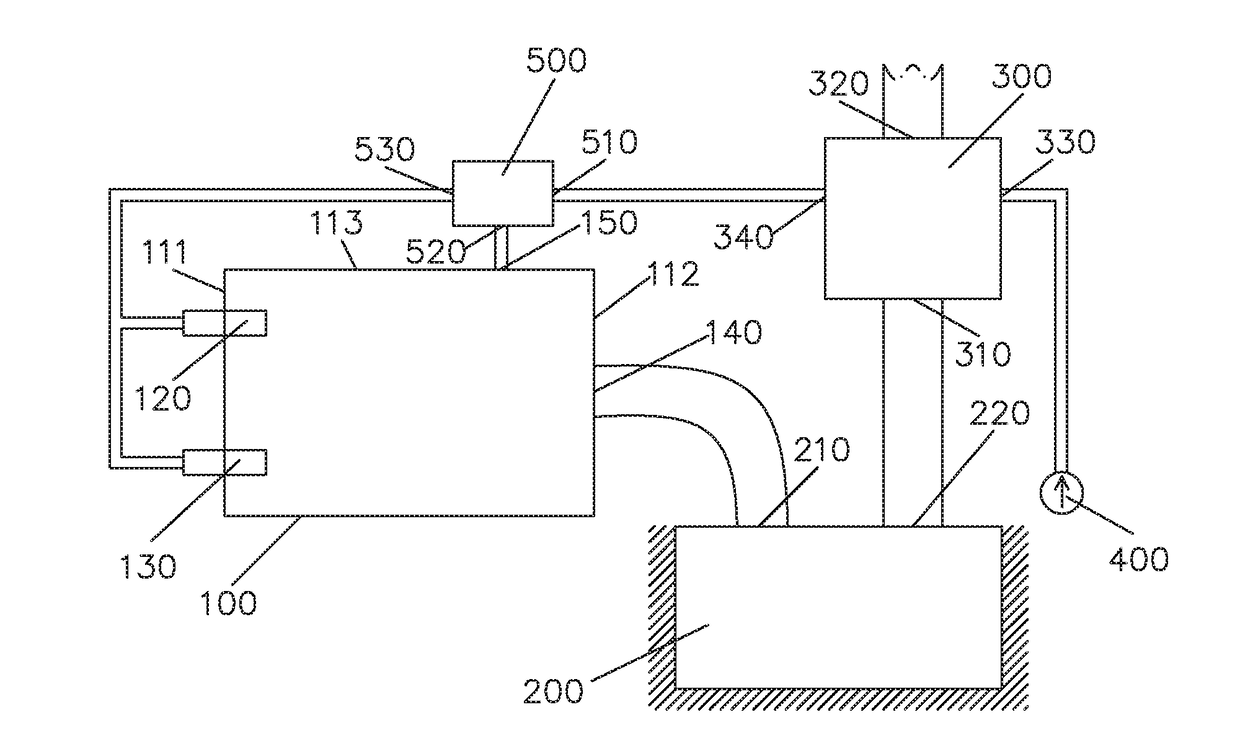

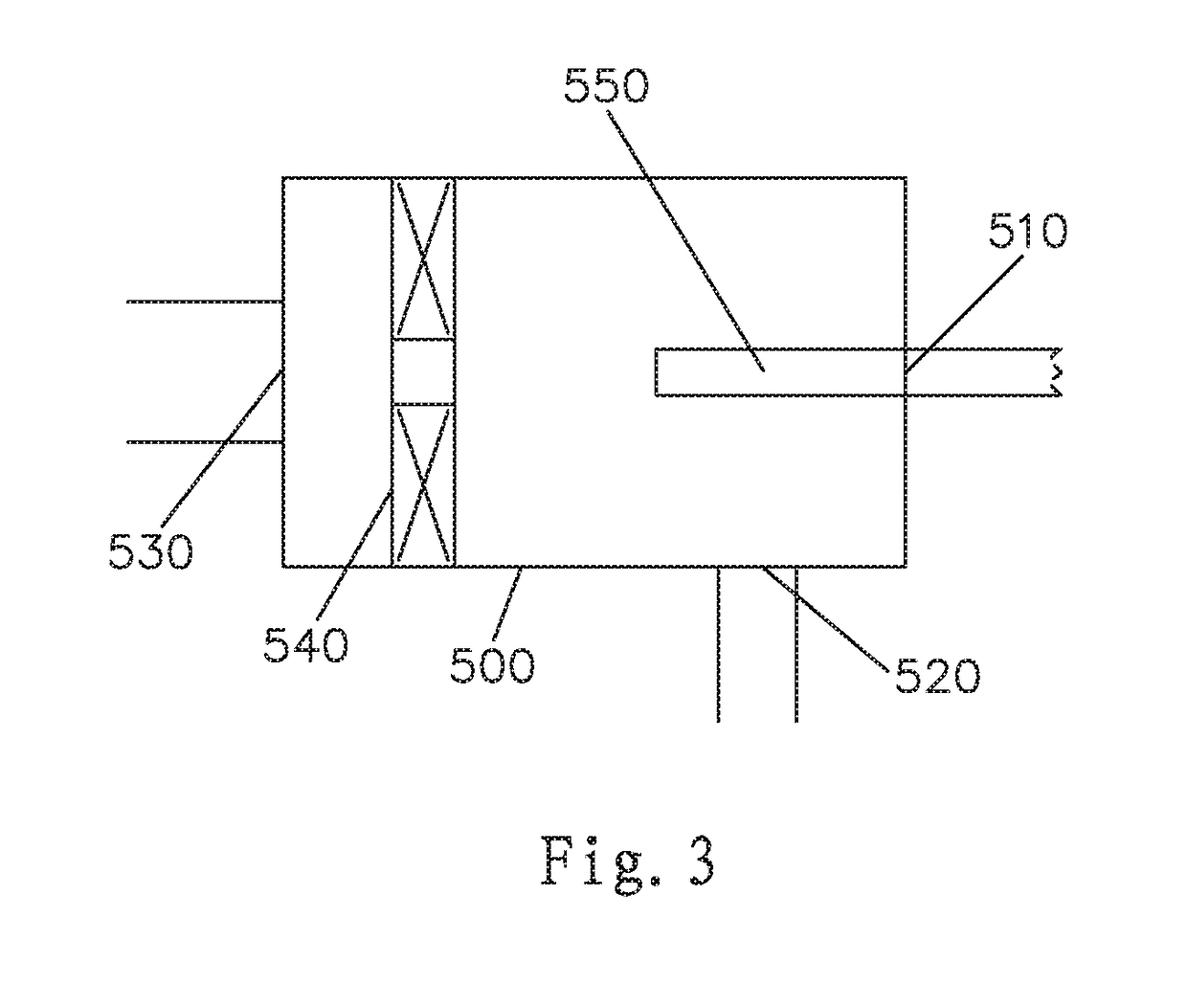

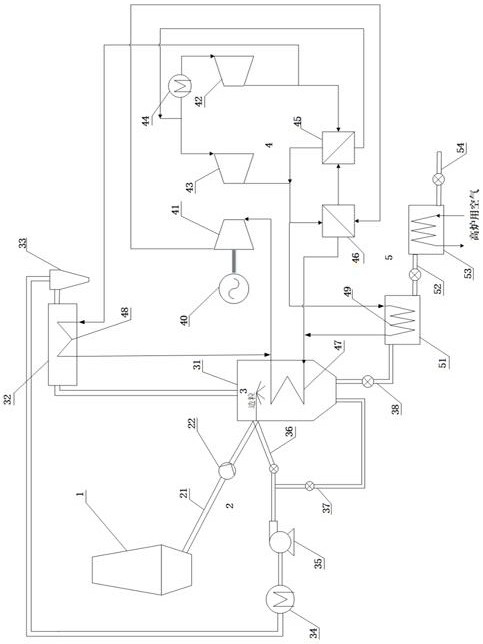

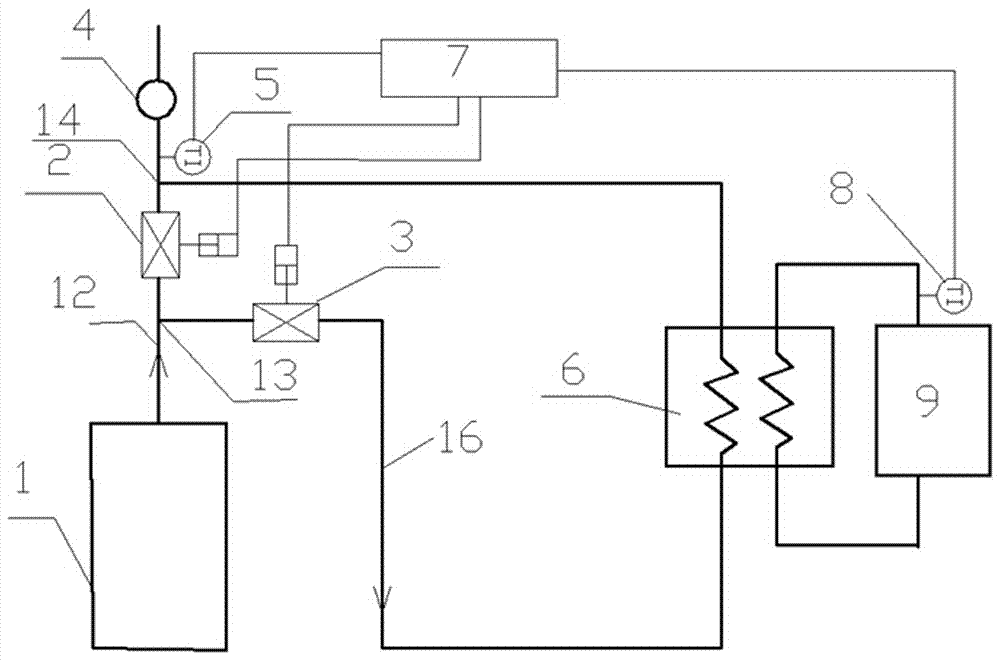

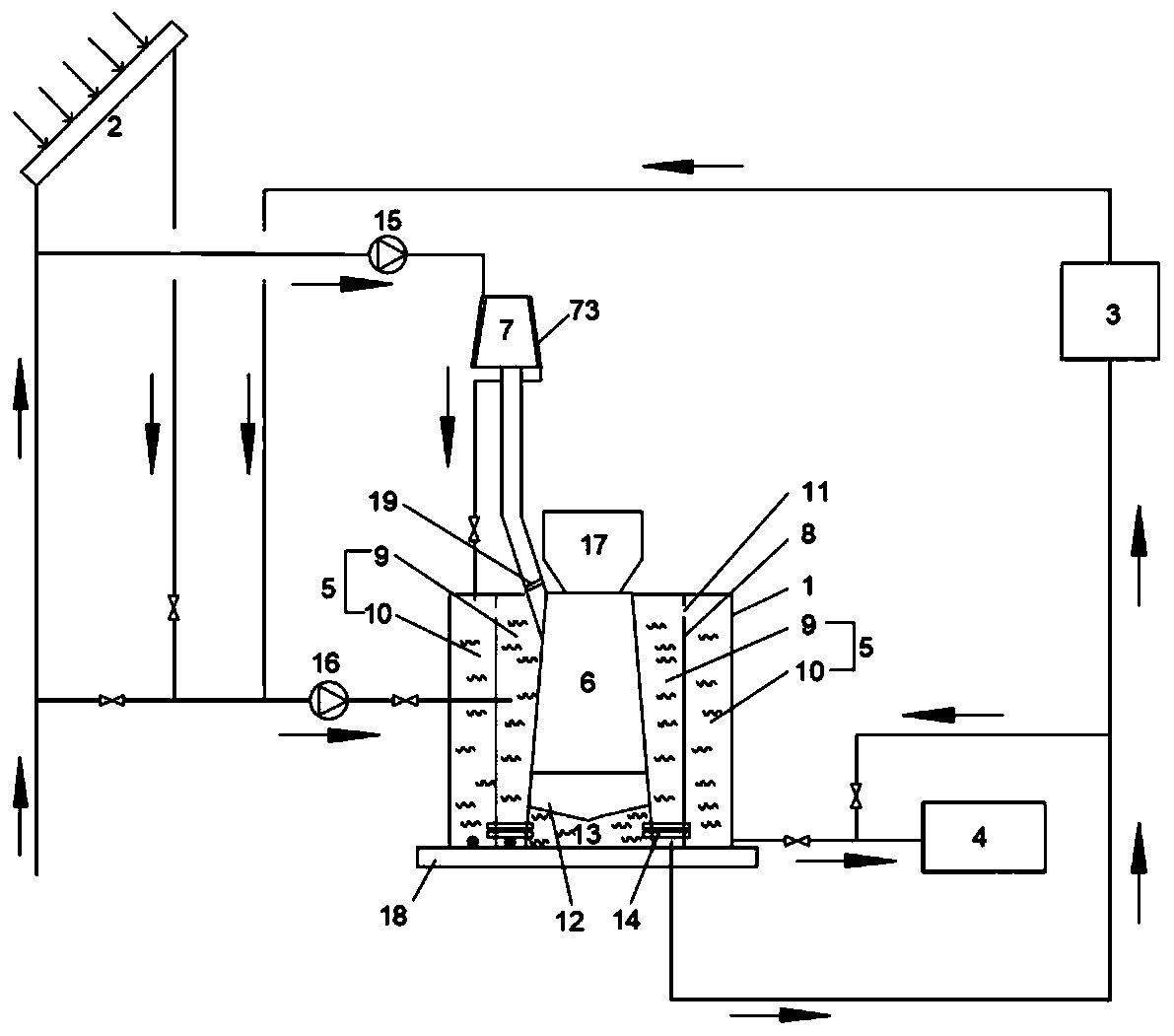

Power station boiler residual heat utilization system capable of achieving intelligent control for fan frequency

InactiveCN105202517AAvoid Low Temperature CorrosionAutomatic adjustment of heating powerCentral heating with accumulated heatBoiler controlData connectionAutomatic control

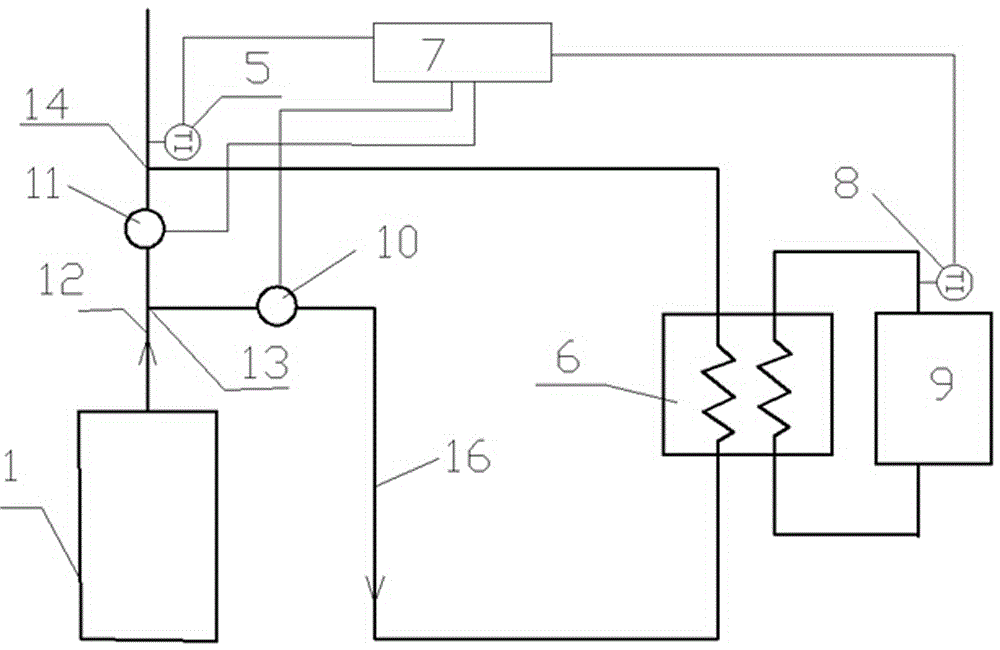

The invention provides a power station boiler residual heat utilization system capable of achieving intelligent control for fan frequency. The system comprises a boiler, a main flue, a bypass flue, a heat exchanger, a flue temperature sensor and a central controller, wherein smoke generated by the boiler enters into the heat exchanger through an inlet of the bypass flue; smoke subjected to heat exchange flows into the main flue via the outlet of the bypass flue and then is discharged; a main flue fan is arranged on the main flue; a bypass flue fan is arranged on the bypass flue; the flue temperature sensor measures the temperature of discharged smoke; the central controller is in data connection with the temperature sensor, the main flue fan and the bypass flue fan; the central controller automatically adjusts the frequency of the main flue fan and the bypass flue fan according to the exhaust gas temperature measured by the temperature sensor. According to the power station boiler residual heat utilization system, the exhaust gas temperature of smoke is automatically controlled through intelligently controlling fan frequency to adjust flow of smoke participating in residual heat utilization and heat exchange, so that low-temperature corrosion is avoided, and intelligentized adjustment of the system is realized.

Owner:ZHONGBEI UNIV

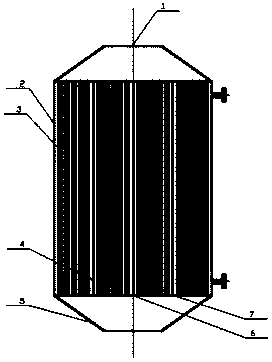

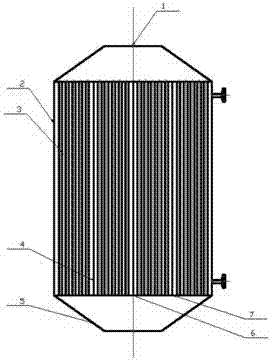

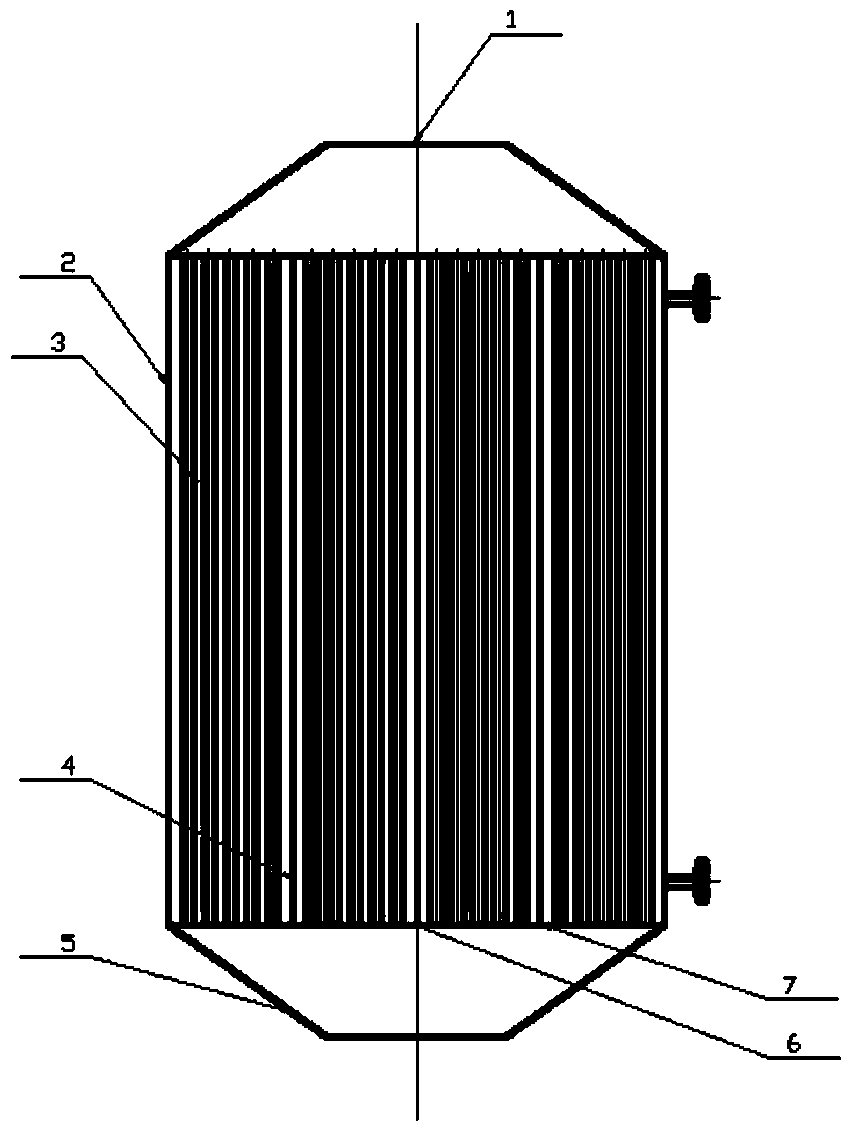

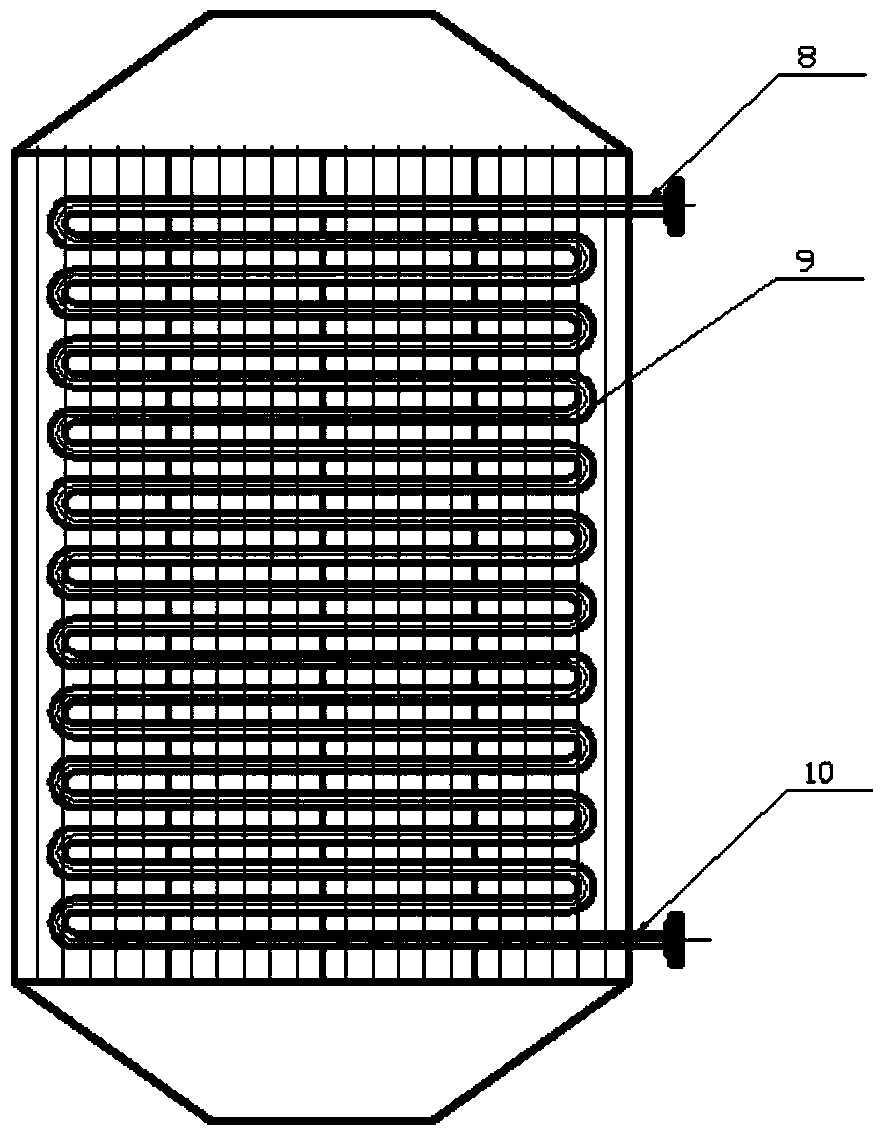

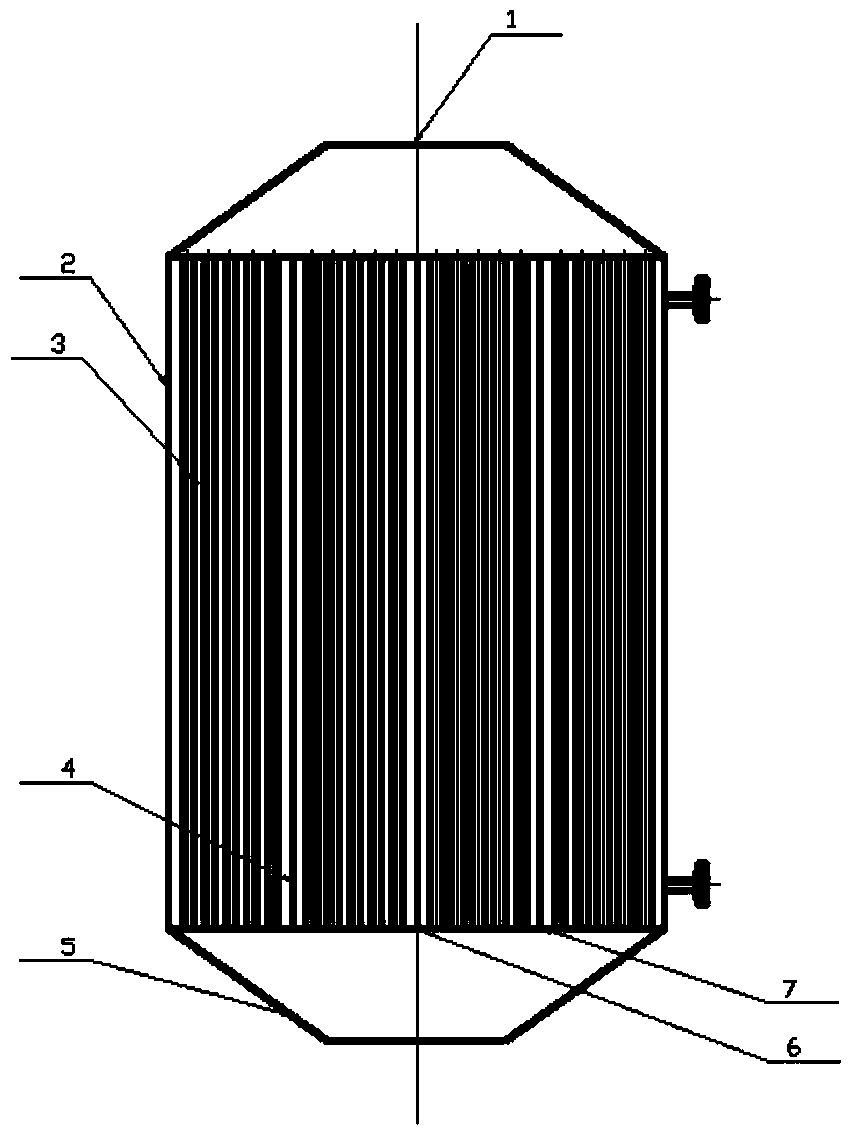

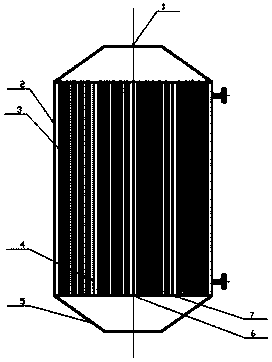

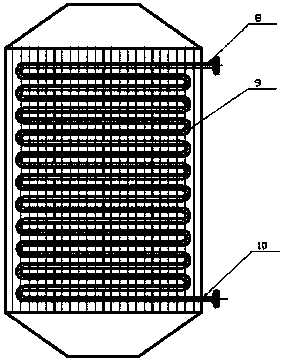

Single-tube-bundle split solid heat accumulation heat exchanger

ActiveCN103925824AAvoid corrosionEasy maintenanceHeat storage plantsHeat exchange apparatusEngineeringMechanical engineering

The invention provides a single-tube-bundle split solid heat accumulation heat exchanger for making use of waste heat produced in the cement producing process. The heat exchanger comprises a low-temperature working medium tube bundle, a high-temperature smoke inlet, a high-temperature smoke outlet, a low-temperature working medium inlet, a low-temperature working medium outlet and a shell, wherein the inside of the heat exchanger shell is provided with a plurality of heat accumulation materials which are solid, the heat accumulation materials are stacked together, each heat accumulation material is provided with a first hole and a second hole, the first hole and the second hole of each heat accumulation materials are crossed but not communicated, the low-temperature working medium tube bundle penetrates through the second hole of each heat accumulation material, the outer diameter of the low-temperature working medium tube bundle is equal to the diameter of the second hole of each heat accumulation material, and the first holes of the heat accumulation materials form a through channel. According to the heat exchanger, waste heat produced in the content production process is made full use of, maximization of heat exchange efficiency is achieved, and the aims of protecting environment and saving energy are achieved.

Owner:山东中和热工科技有限公司

A power plant boiler waste heat utilization system with intelligent control of fan frequency

InactiveCN105202517BAvoid Low Temperature CorrosionWaste heat utilization meetsCentral heating with accumulated heatBoiler controlData connectionAutomatic control

The invention provides a power station boiler residual heat utilization system capable of achieving intelligent control for fan frequency. The system comprises a boiler, a main flue, a bypass flue, a heat exchanger, a flue temperature sensor and a central controller, wherein smoke generated by the boiler enters into the heat exchanger through an inlet of the bypass flue; smoke subjected to heat exchange flows into the main flue via the outlet of the bypass flue and then is discharged; a main flue fan is arranged on the main flue; a bypass flue fan is arranged on the bypass flue; the flue temperature sensor measures the temperature of discharged smoke; the central controller is in data connection with the temperature sensor, the main flue fan and the bypass flue fan; the central controller automatically adjusts the frequency of the main flue fan and the bypass flue fan according to the exhaust gas temperature measured by the temperature sensor. According to the power station boiler residual heat utilization system, the exhaust gas temperature of smoke is automatically controlled through intelligently controlling fan frequency to adjust flow of smoke participating in residual heat utilization and heat exchange, so that low-temperature corrosion is avoided, and intelligentized adjustment of the system is realized.

Owner:ZHONGBEI UNIV

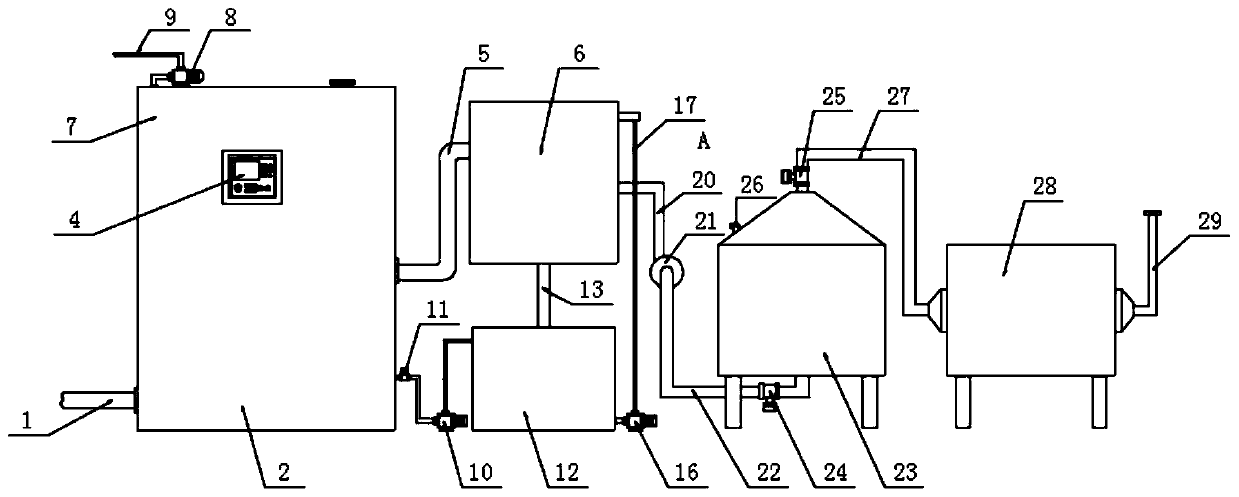

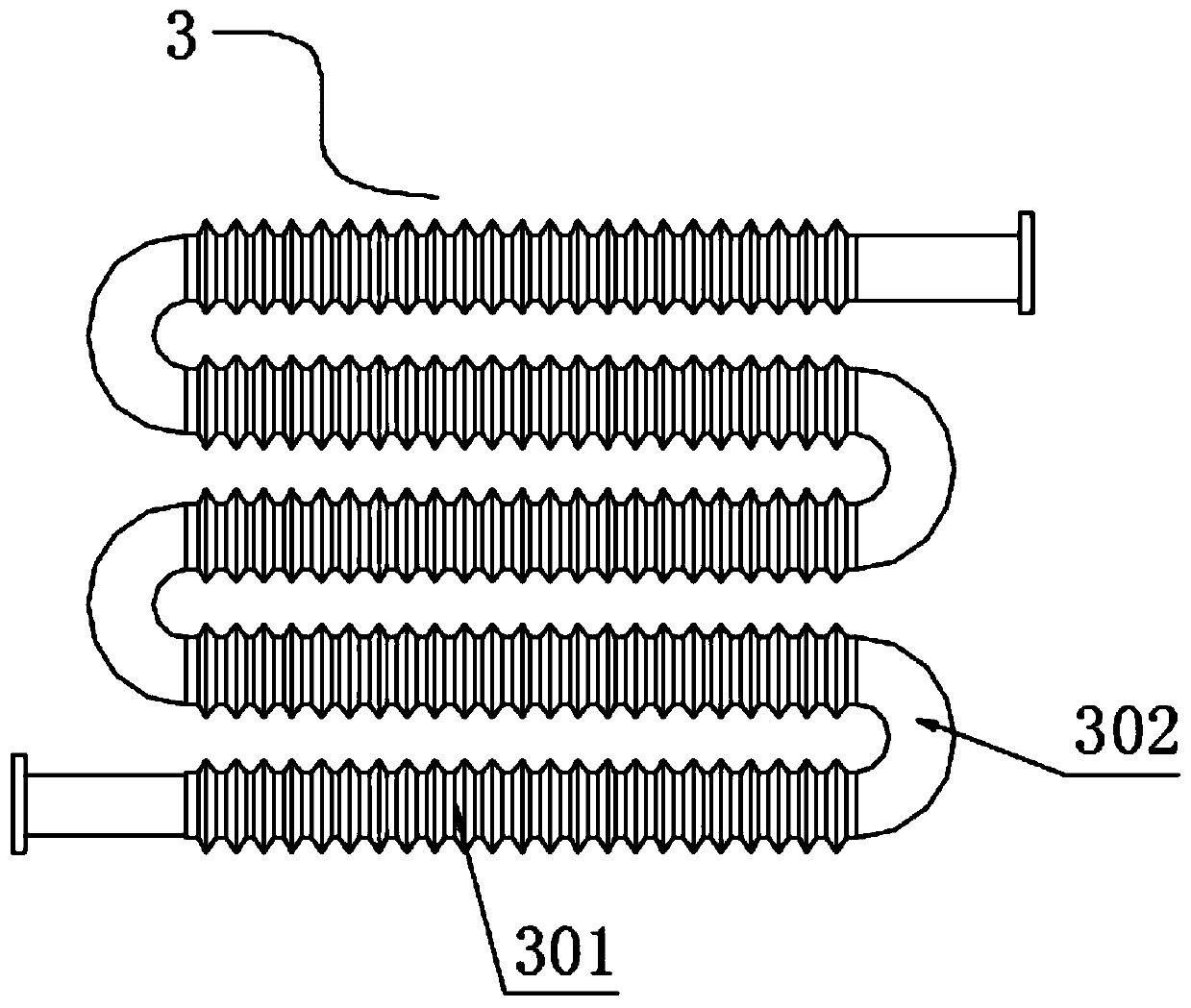

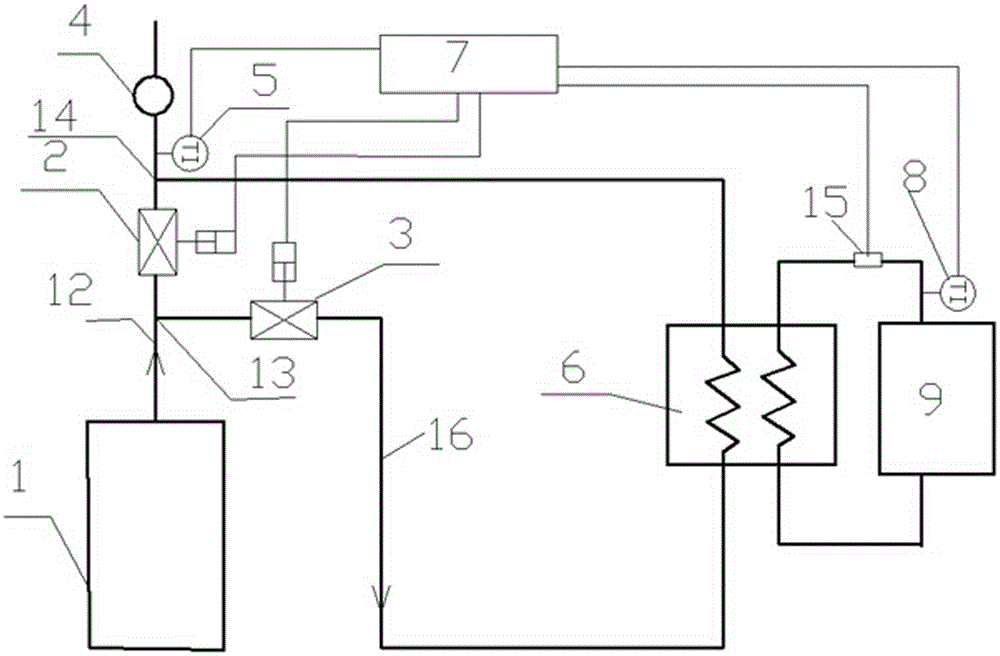

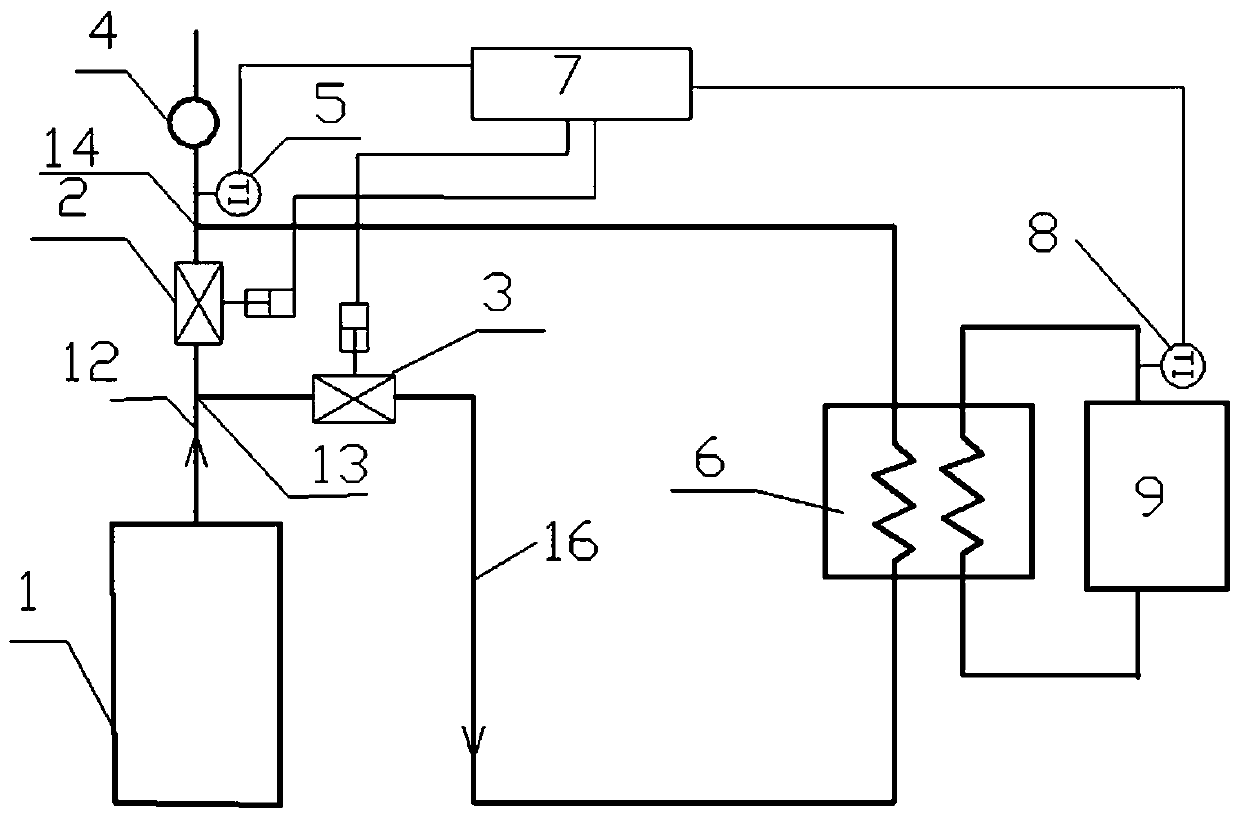

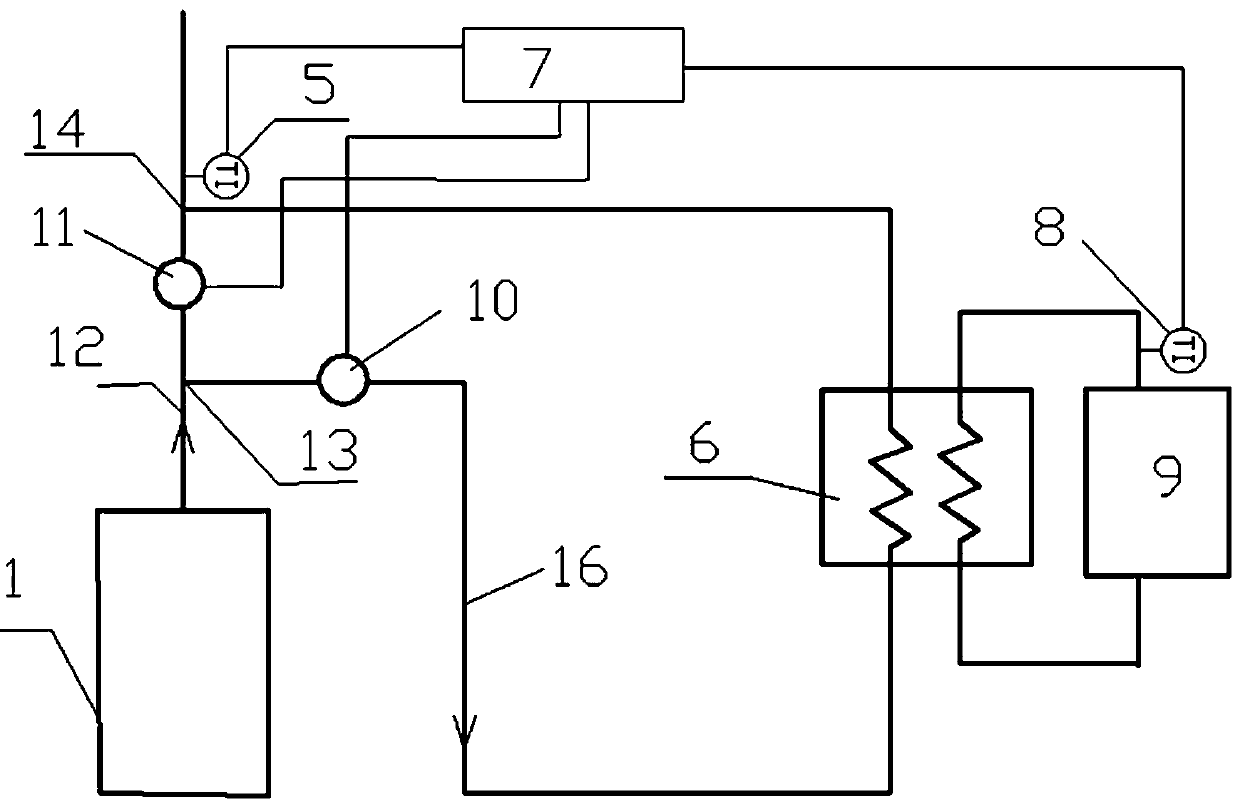

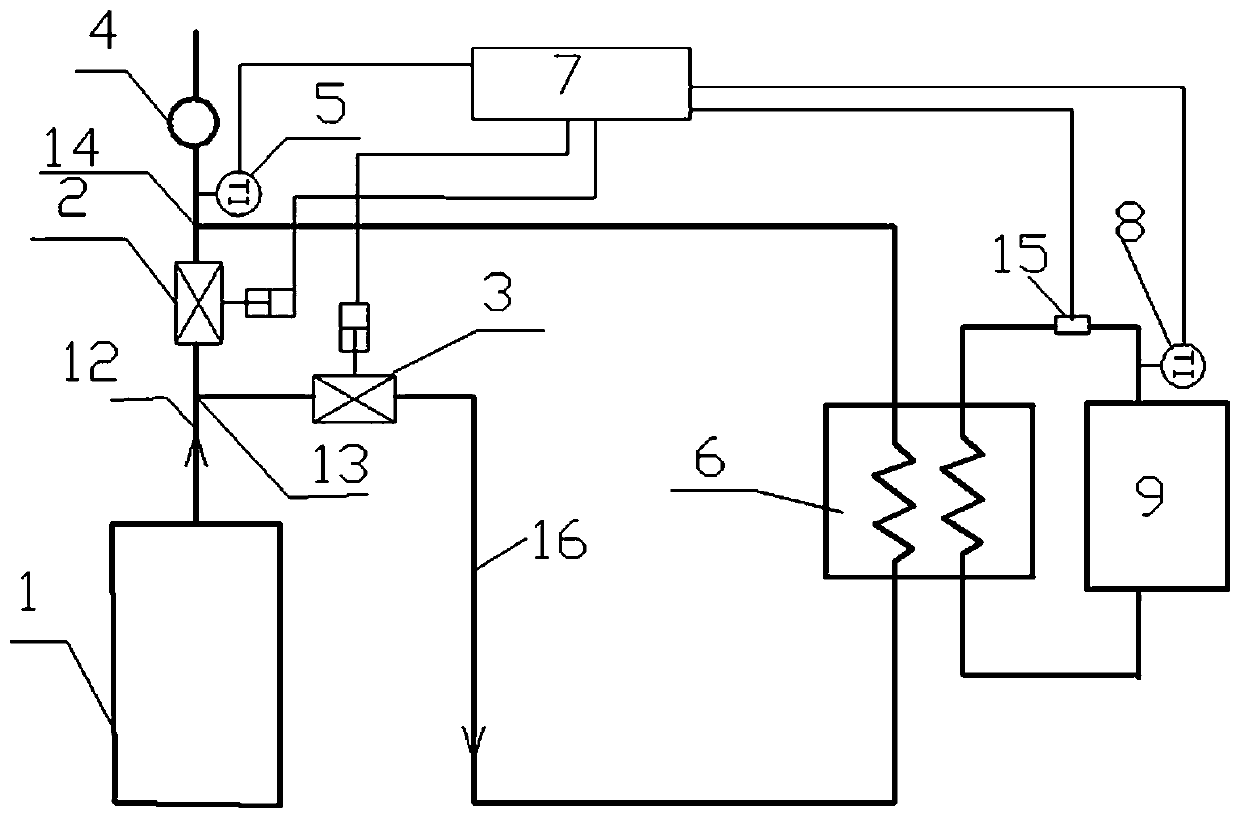

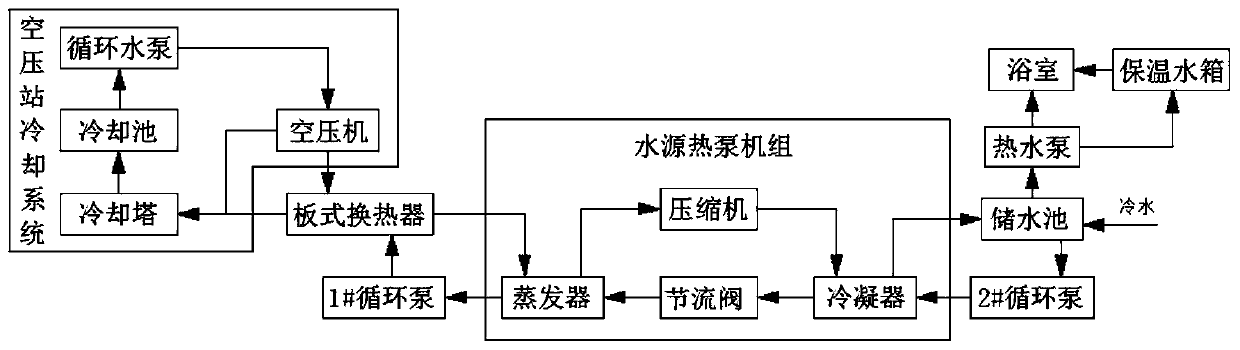

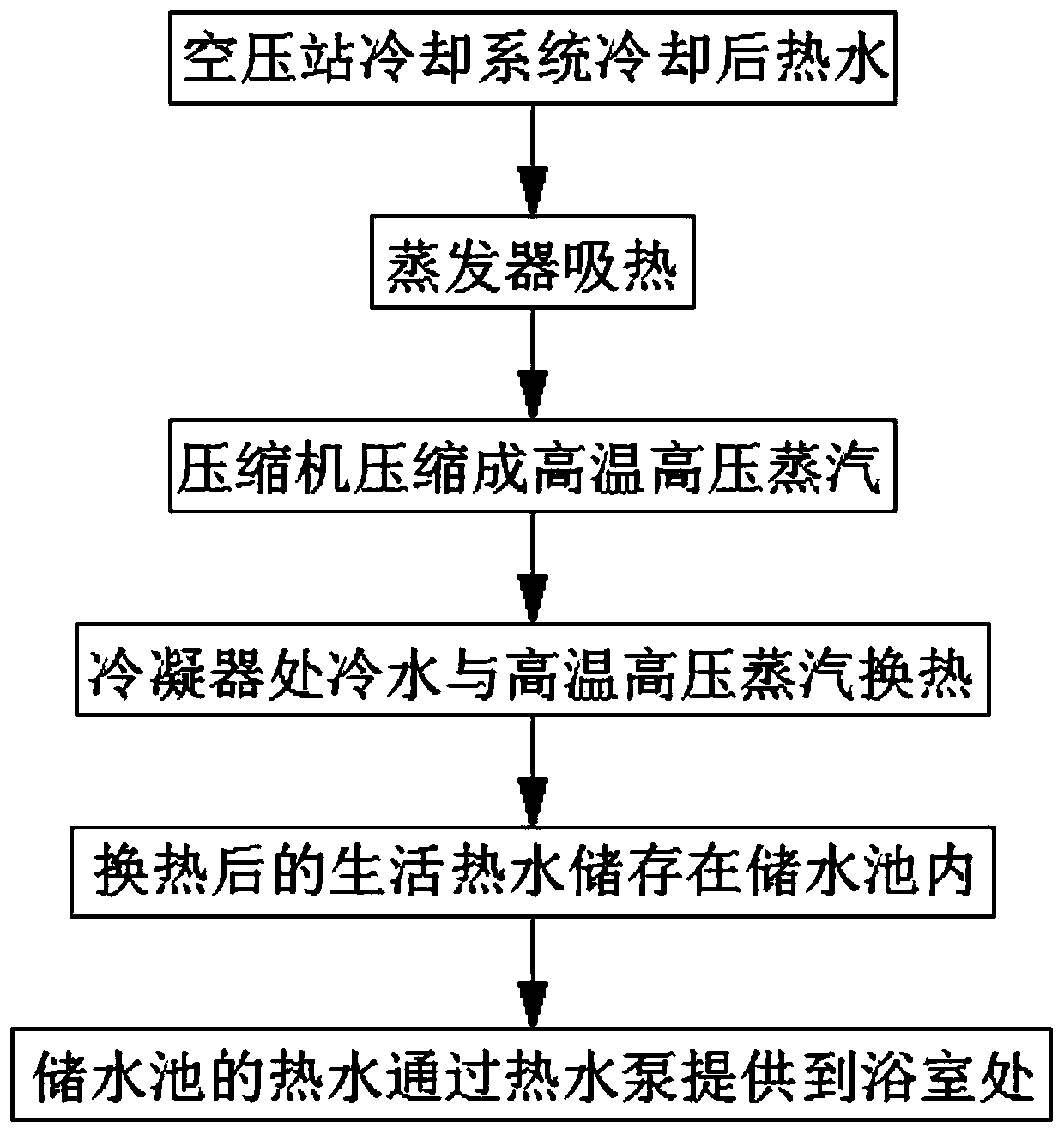

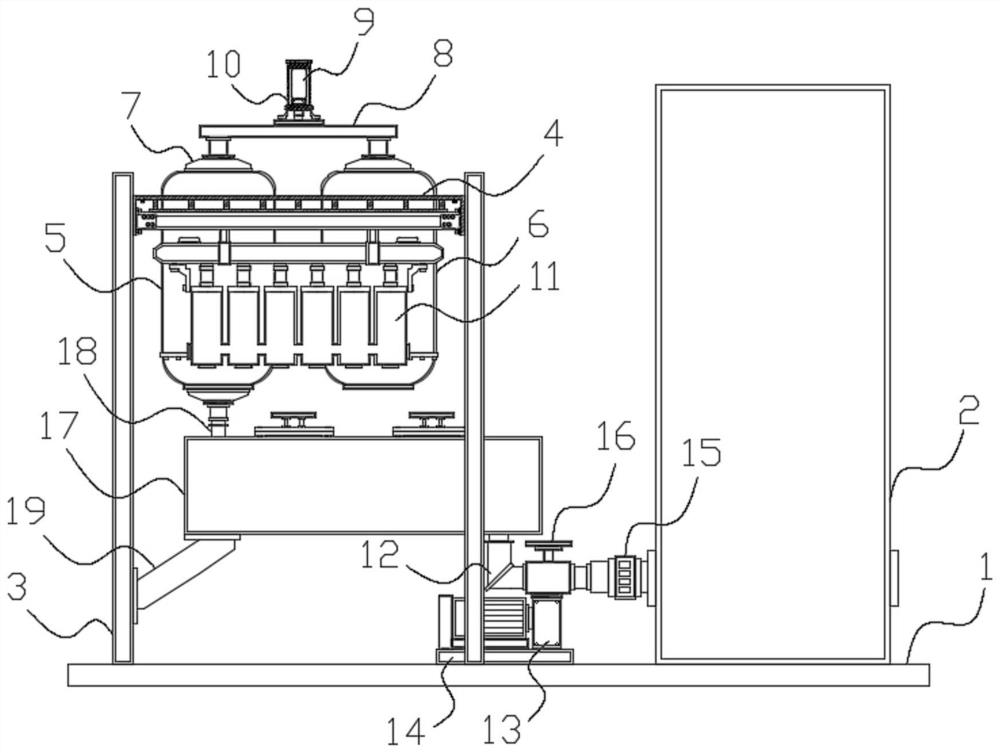

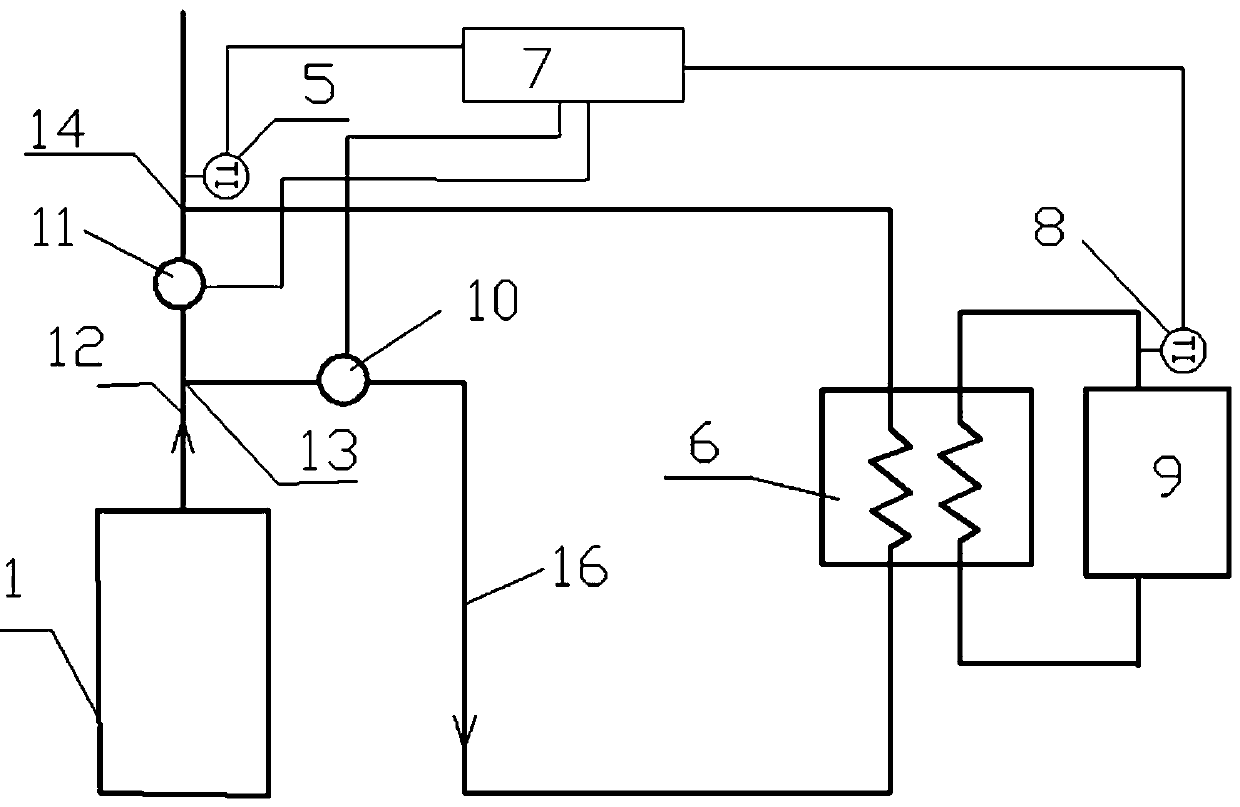

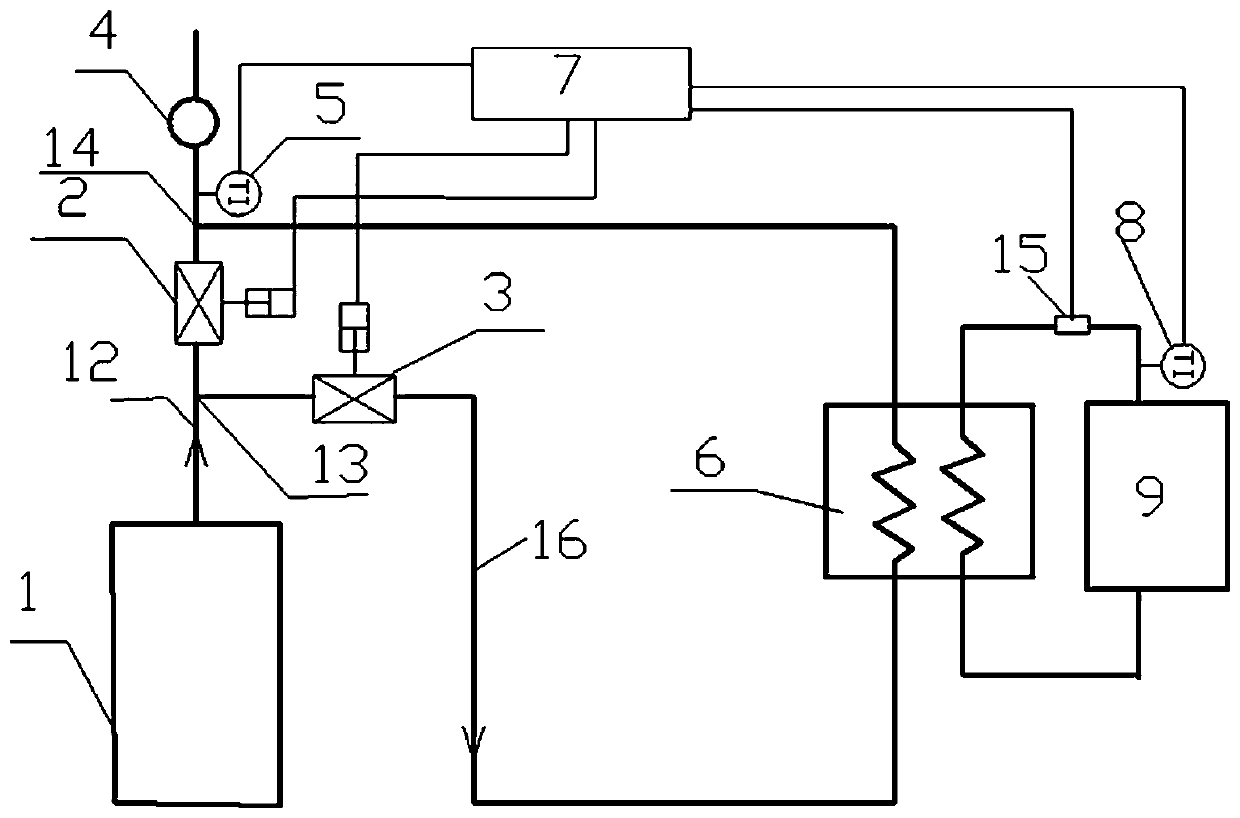

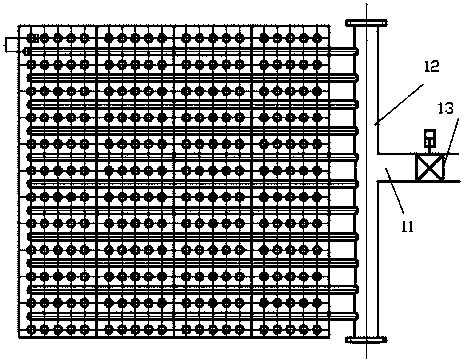

Air compression station waste heat recovery system based on water source heat pump unit

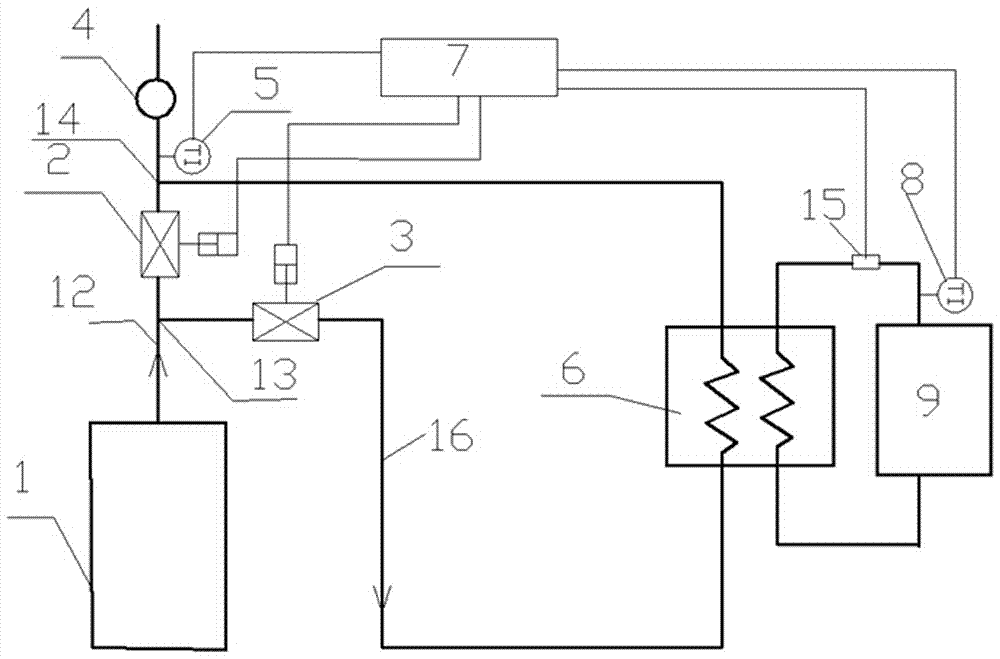

PendingCN110762898AImprove effective utilizationImprove waste heat utilization effectHeat pumpsPositive displacement pump componentsCooling towerWater storage tank

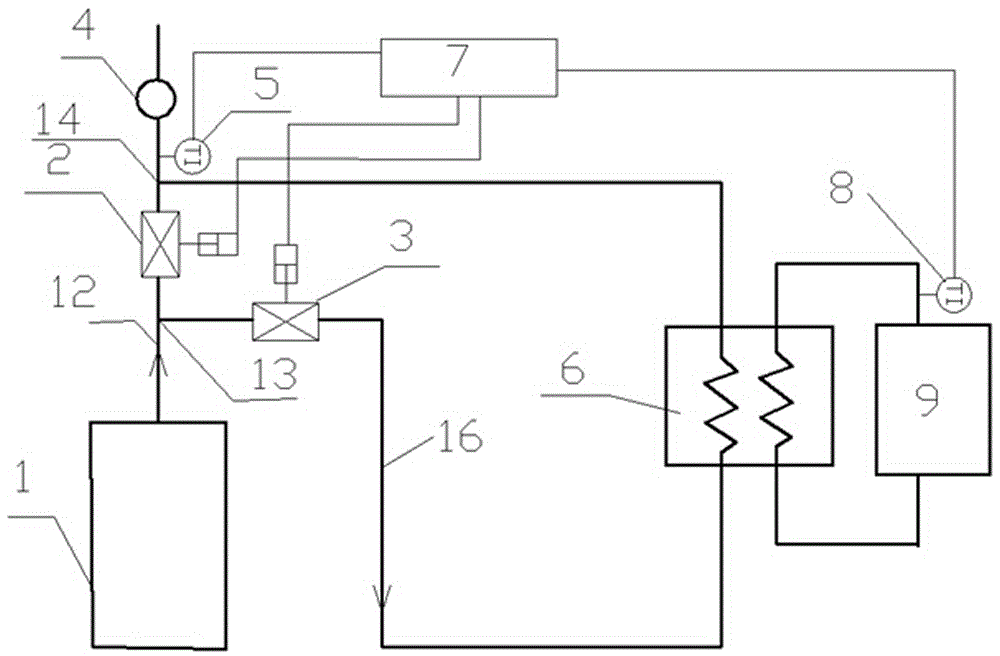

The invention relates to the technical field of air compression station waste heat recovery, and discloses an air compression station waste heat recovery system based on a water source heat pump unit.The air compression station waste heat recovery system based on the water source heat pump unit comprises the water source heat pump unit, an air compression station cooling system and a water storage tank, wherein the water source heat pump unit is mainly composed of a compressor, an evaporator and a condenser, the air compression station cooling system is mainly composed of an air compressor, acirculating water pump, a cooling tank and a cooling tower, a water conveying pipeline with a circulation loop is connected between the air compressor, the cooling tower, the cooling tank and the circulating water pump, and a water conveying pipeline with a circulation loop is connected between the compressor, the condenser and the evaporator. According to an air compression station waste heat recovery system based on the water source heat pump unit, heat energy is extracted from an air compression station cold zone system through the water source heat pump unit, after pressurizing is carriedout through the compressor, high-temperature high-pressure steam is formed, the high-temperature high-pressure steam is exchanged with cold water on the condenser side, domestic hot water is prepared, low-grade energy can be converted into high-grade energy by relying on a small amount of electric energy input to drive the air compressor, and the efficiency of efficient utilization of waste heatof the air compression station cooling system is improved.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Flue gas treatment device and rotary hearth furnace high-temperature and high-dust glue gas treatment system

InactiveCN106195968AReduce heating surfaceReduce congestionIncreasing energy efficiencySteam generation plantsSuperheaterHearth

The invention discloses a flue gas treatment device and a rotary hearth furnace high-temperature and high-dust glue gas treatment system with the flue gas treatment device. The treatment device comprises a sedimentation furnace, a high-temperature waste heat boiler, a low-temperature waste heat boiler and a steam drum. At least part of heated walls of the sedimentation furnace are water-cooling walls. The steam drum is provided with a water inlet, a water outlet, a gas inlet and a gas outlet. The water outlet communicates with heat exchange medium inlets of all the water-cooling walls. The gas inlet communicates with heat exchange medium outlets of all the water-cooling walls. The water inlet communicates with a heat exchange medium outlet of the low-temperature waste heat boiler, and the gas outlet communicates with a heat exchange medium inlet of the high-temperature waste heat boiler. According to the flue gas treatment device, due to the fact that the heated faces in the sedimentation furnace are reduced, the waste heat utilization rate and effect of flue gas can be effectively improved, meanwhile, the phenomenon of blockage of a superheater, a body flue of a coal economizer and subsequent flues is reduced, and the corrosion situation caused by the flue gas to equipment is effectively improved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY +1

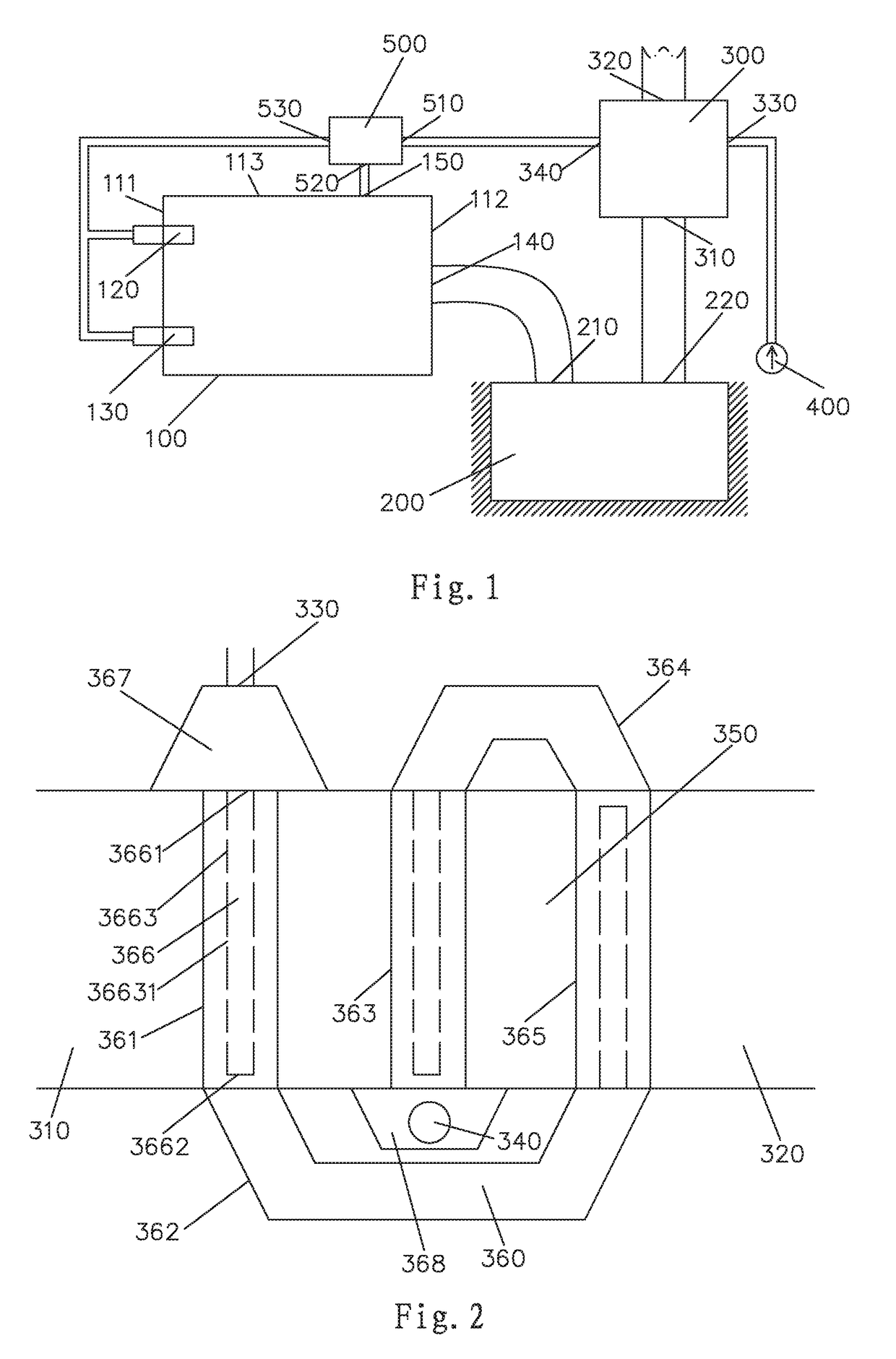

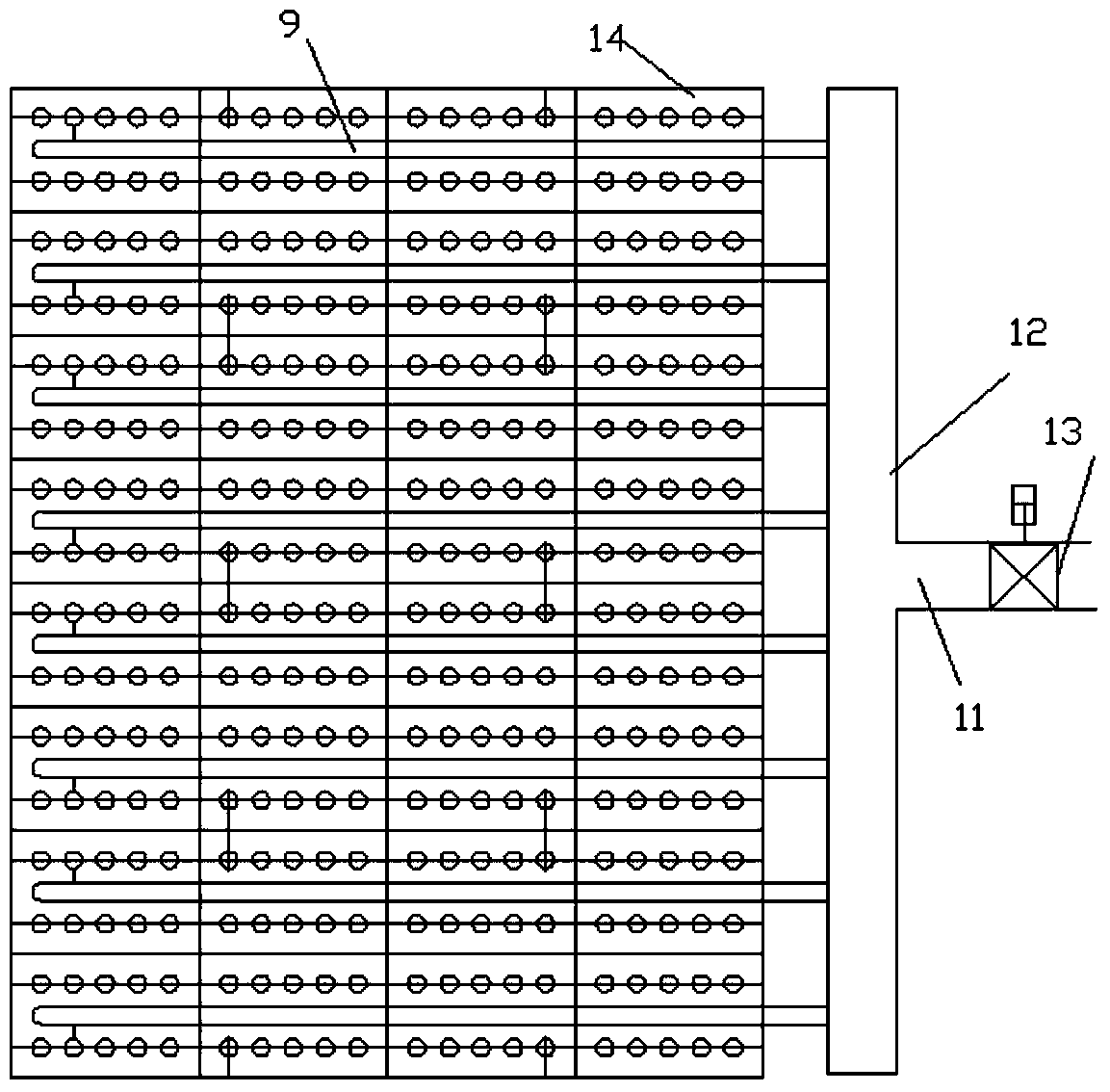

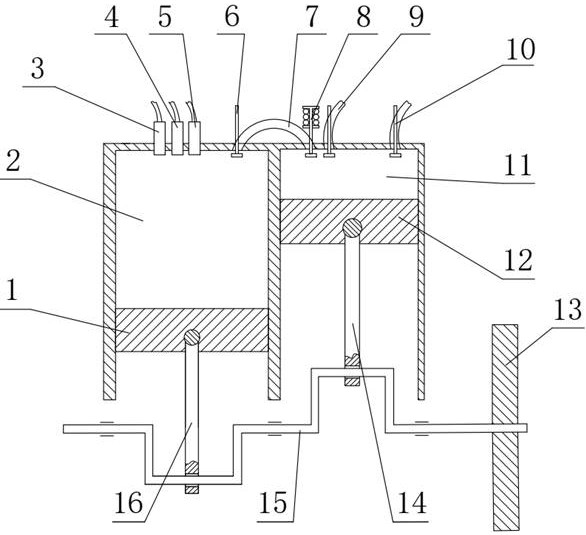

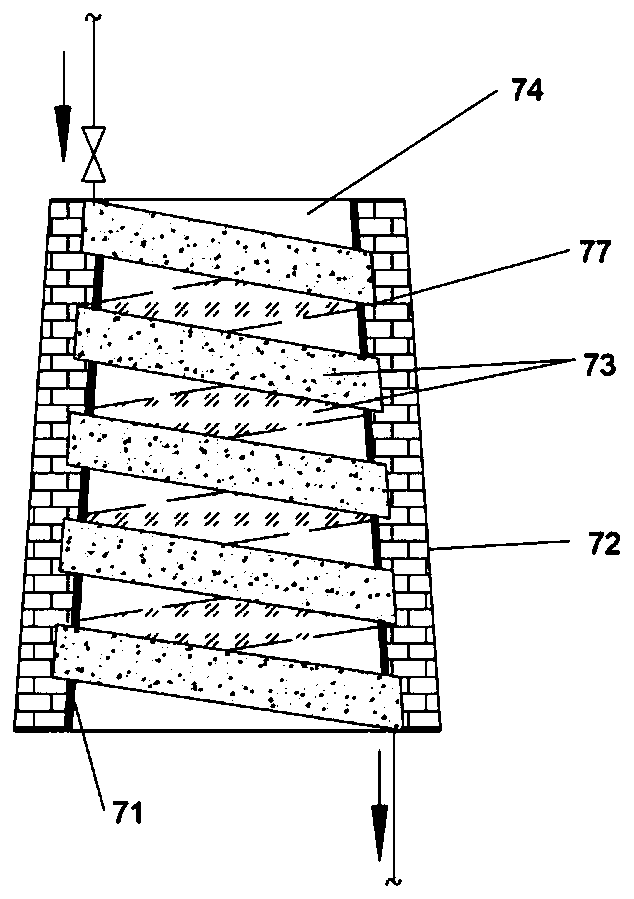

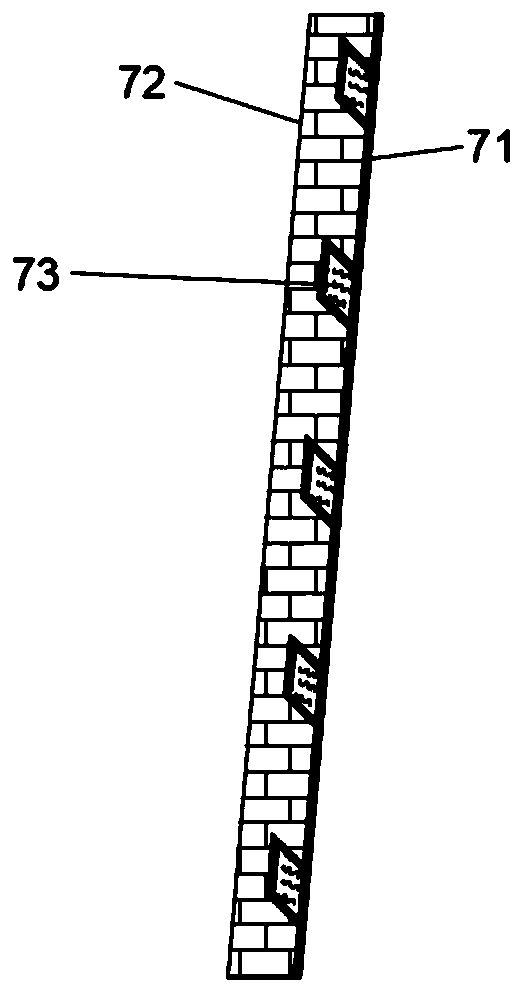

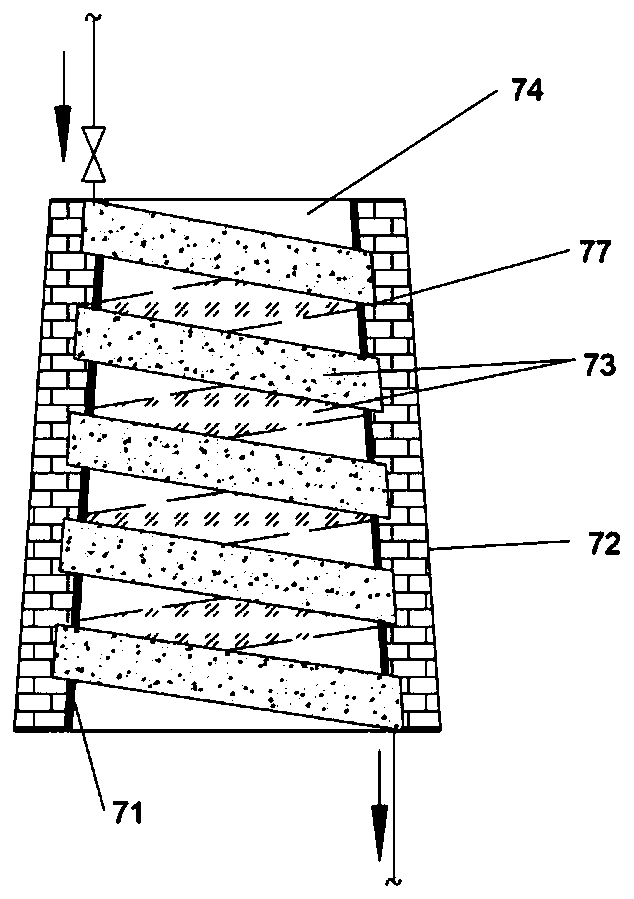

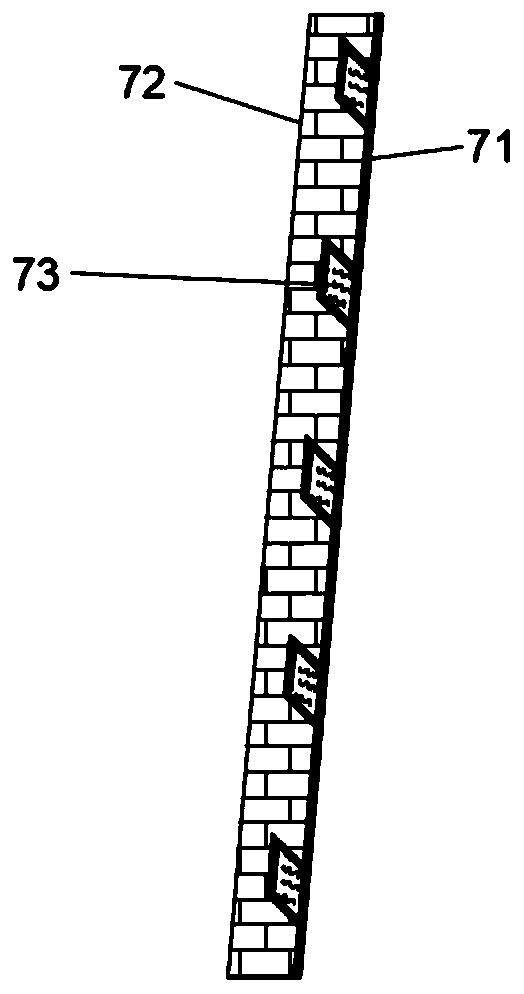

Regenerative heat exchanger and exhaust gas inlet device of regenerative heat exchanger

ActiveCN103940276AEasy maintenanceLow costHeat storage plantsChimneysEngineeringMechanical engineering

The invention provides a smoke inlet device, including an adjustable smoke baffle, a smoke dusting baffle, a shell, a dusting pipeline, and a smoke inlet pipeline, wherein the smoke inlet pipeline is arranged at a lower end, a smoke outlet end is arranged at an upper end, the dusting pipeline is arranged in the shell for housing and collecting the dust in the smoke, a regular dusting mechanism is connected to the inferior of the dusting pipeline; the shell is composed of a first vertical segment at the lower end, an outward incline segment connected to the first vertical segment, a second vertical segment connected to the incline segment and a horizontal segment arranged at top and connected to the second vertical segment, the adjustable smoke baffle is connected to the other end portion of the horizontal segment and adjusts the angle around the other end portion of the horizontal segment; the first vertical segment forms a smoke inlet, the dusting pipeline goes deep into the shell from the smoke inlet, the smoke dusting baffle is connected to the upper end portion of the dusting pipeline arranged in the shell; in the vertical direction, and the upper end and the lower end of the smoke dusting baffle are arranged between the upper end and the lower end of the second vertical segment. The repeatedly efficient dust removal of smoke can be realized, the dust stratification problem of devices in the flue is reduced to a large extent, and the heat exchange efficiency after the smoke enters a heat exchanger is improved.

Owner:山东中和热工科技有限公司

Continuous low oxygen and high temperature combustion aluminum melting furnace with porous injection pipe heat exchanger

ActiveUS20180224208A1Extended service lifeLow costCrucible furnacesWaste heat treatmentCold airCombustion

A continuous aluminum melting furnace with a porous spray pipe heat exchanger, comprising a furnace body, combustion nozzles, a smoke pipeline and a heat exchanger. The heat exchanger comprises a smoke channel and heat exchange cylinders, wherein each of the heat exchange cylinders comprises a head end, a tail end, and a porous spray pipe in at least one of the cylinders. The porous spray pipe comprises a closed end and a pipe body, with several air spray holes provided on a peripheral wall of the pipe body so that cold air entering the at least one heat exchange cylinder is sprayed to an inner wall of the cylinder so as to exchange heat with high-temperature smoke which flows through an outer wall of the cylinder, thus keeping the temperature of the cylinder lower than the rated tolerant temperature of the material from which the cylinder is made.

Owner:GUANGDONG UNIV OF TECH

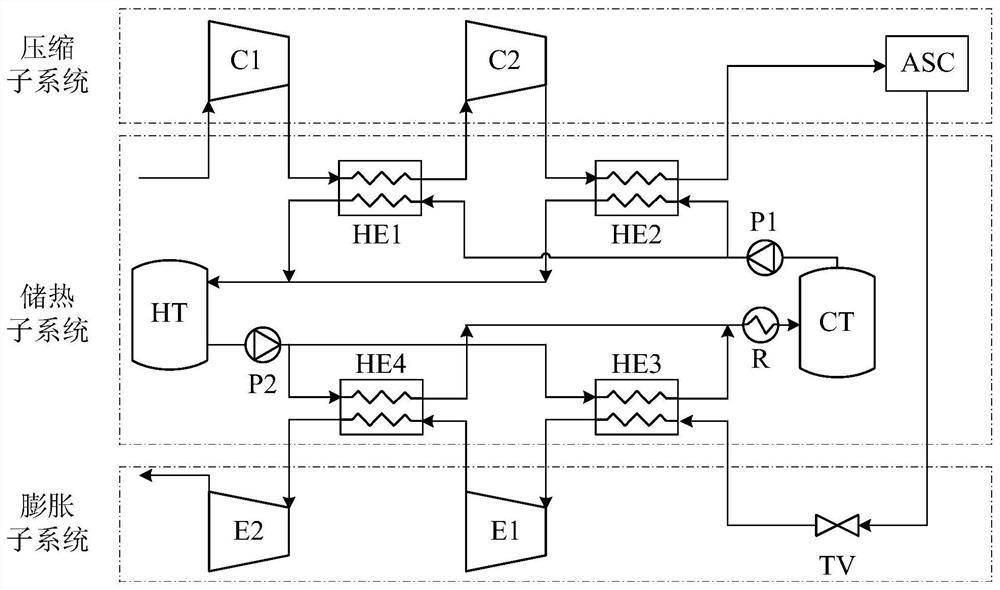

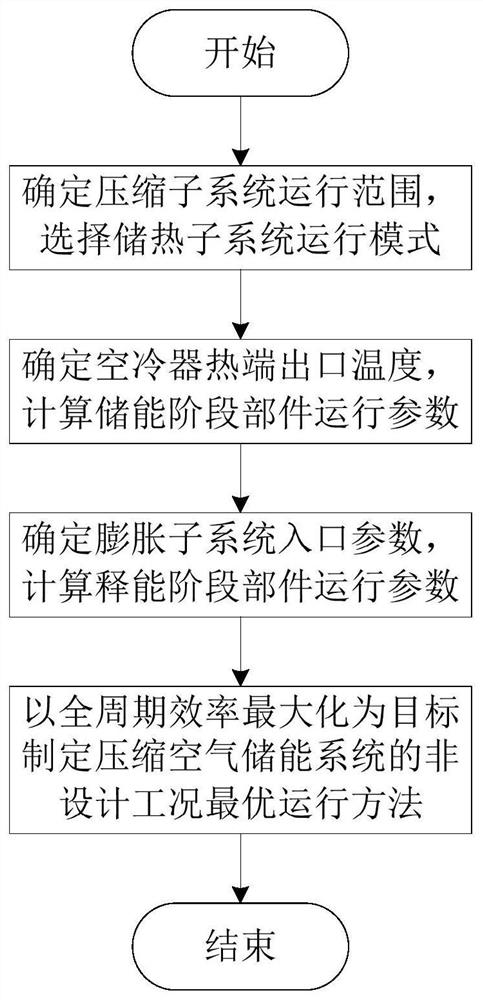

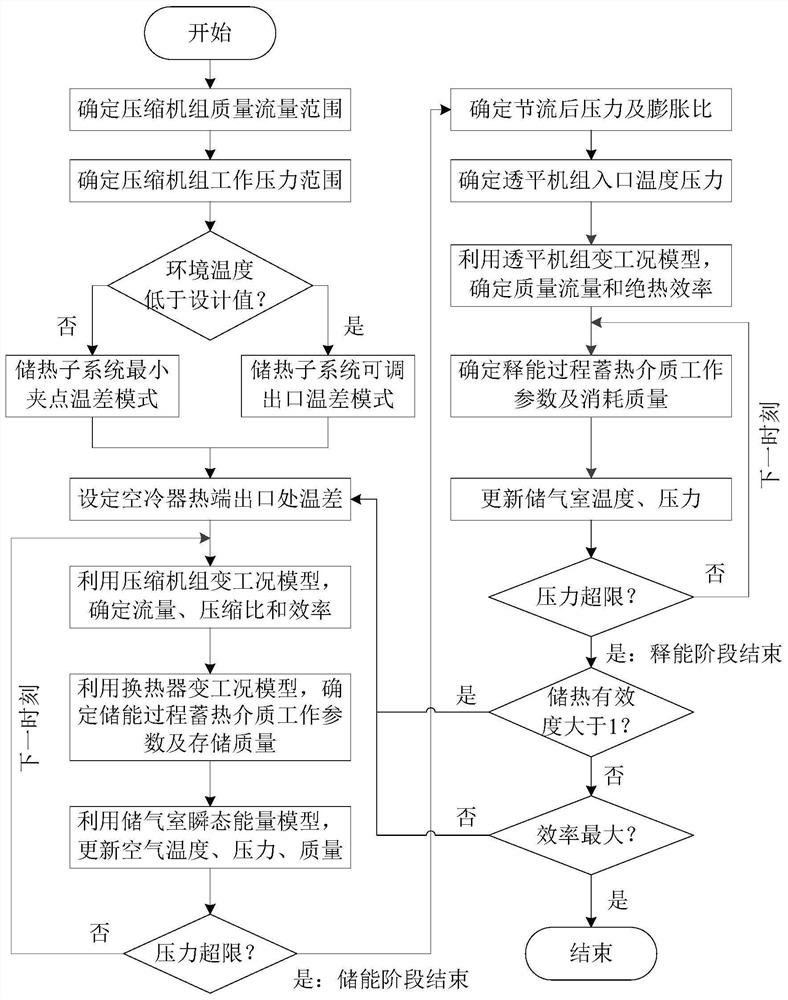

Non-design working condition operation method of compressed air energy storage system

ActiveCN114033730AImprove running stabilityImprove energy efficiencyHeat storage plantsCombination enginesProcess engineeringControl theory

The invention discloses a non-design working condition operation method of a compressed air energy storage system. The method comprises the following steps of: determining an operation range of a compression subsystem according to a system operation environment temperature, and selecting an operation mode of a heat storage subsystem; setting an air cooler hot end outlet temperature difference, and establishing an energy storage stage component parameter regulation and control model; determining operation parameters of an expansion subsystem, and establishing an energy release stage component parameter regulation and control model; and establishing a full-cycle efficiency optimal operation model of the system. The influence of environment state change on main working parts of the compressed air energy storage system is comprehensively considered, the parameter operation range of the system under the variable working conditions is determined, and the operation stability is improved. The operation mode of the heat storage subsystem is selected according to the environment temperature, operation parameters are optimized, the energy conversion and waste heat utilization effects are effectively improved, energy efficiency maximization of the system within the whole environment temperature range is achieved, the whole-period efficiency higher than the design working condition is obtained, and the operation stability and the variable working condition performance of the compressed air energy storage system under the variable working condition are improved.

Owner:XI AN JIAOTONG UNIV

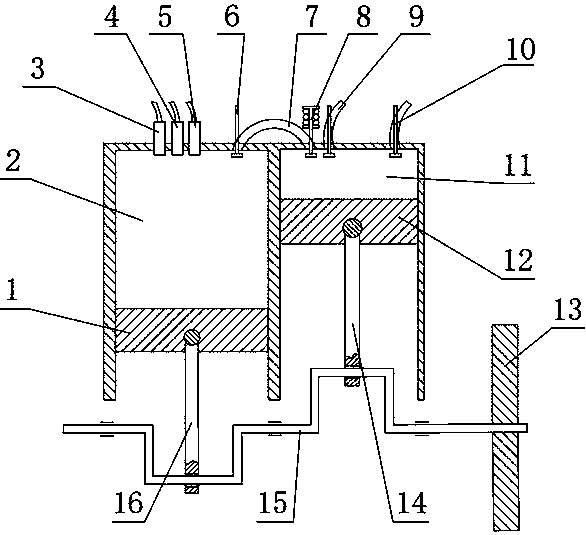

Heat-accumulating type heat exchanger and steam-water separator thereof

ActiveCN103954158AAvoid corrosionEasy maintenanceHeat storage plantsSteam separation arrangementsMechanical engineeringMechanics

The invention provides a steam and water separator, including a shell, a separation tube, a steam inlet pipe, a circle segment orifice plate 1, a circle segment orifice plate 2, a porous orifice plate, a connection tube and a steam outlet tube. The steam and water separator is vertically arranged. The steam inlet tube and the steam outlet tube of the steam and water separator are respectively arranged at the bottom and the top positions of the separator. A water outlet tube is arranged at the bottom side of the shell. The separation tube is divided into two segments. The two segments are connected through a middle connection tube. An exit end of the steam inlet tube and an exit end of the steam outlet tube are respectively inserted in the two segments of the separator. The circle segment orifice plate 1 and the circle segment orifice plate 2 are arranged at the steam inlet end and the outlet end in the connection tube. Orifices of the circle segment orifice plates are arranged at different sides of the connection tube. The porous orifice is arranged at a second segment in the separation tube at the steam outlet end. Small holes are opened on the orifice plates and distrusted in a circle center. The invention provides a novel separator for thoroughly separating the steam and water.

Owner:山东中和热工科技有限公司

Methanol-high-pressure-oxygen compound two-stroke engine and control method thereof

ActiveCN111287847ARealize work cycleReduce power consumptionElectrical controlInternal combustion piston enginesExhaust valveInlet valve

The invention discloses a methanol-high-pressure-oxygen compound two-stroke engine. The methanol-high-pressure-oxygen compound two-stroke engine is composed of one or more air cylinder groups, each air cylinder group comprises a main air cylinder and a corresponding auxiliary air cylinder, and the main air cylinders are provided with starting fuel nozzles, methanol nozzles, oxygen nozzles and mainair cylinder exhaust valves and are not provided with air inlet valves; and connection channels are arranged between main air cylinder exhaust ports and the auxiliary air cylinders, the connection channels are provided with one-way valves at auxiliary air cylinder inlets, air in the main air cylinders only flows into the auxiliary air cylinders through the one-way valves, the auxiliary air cylinders are not provided with fuel nozzles and are provided with auxiliary air cylinder air inlet valves and auxiliary air cylinder exhaust valves, and the auxiliary air cylinder air inlet valves communicate with an engine air inlet pipe. Methanol is injected into the main air cylinders, the amount of oxygen injected in the main air cylinders is controlled, the degree of fuel combustion is controlled,high-temperature active air which is not completely burned in the main air cylinders is introduced into the auxiliary air cylinders to continue combustion, the cylinder-dividing circulation is achieved, the emission of harmful air is reduced, and the full combustion of fuel is achieved.

Owner:ANYANG INST OF TECH

Waste heat utilization device of air compressor

InactiveCN112923761AEasy to drinkEasy to cleanCorrosion preventionHeat exchanger casingsWater storagePlate heat exchanger

The invention discloses a waste heat utilization device of an air compressor. A base and an output pipeline are included, a plate heat exchanger body is mounted on one side of the surface of the base, two mounting frames are welded to the surface, on one side of the plate heat exchanger body, of the base, and a mounting mechanism is arranged between the two mounting frames. A first water storage tank and a second water storage tank are assembled on the mounting mechanism, top covers are arranged at the tops of the first water storage tank and the second water storage tank correspondingly, the two ends of an output pipeline penetrate through the two top covers correspondingly and communicate with the first water storage tank and the second water storage tank correspondingly, and cleaning mechanisms are assembled on the first water storage tank and the second water storage tank correspondingly . Hot water output after the plate heat exchanger body completes heat conversion work is conveyed into the water storage tanks through cooperation of a water pump and the pipeline, impurities possibly existing in the hot water are fully filtered out through a filtering mechanism in the period, and therefore the overall waste heat utilization effect is improved.

Owner:胡煜

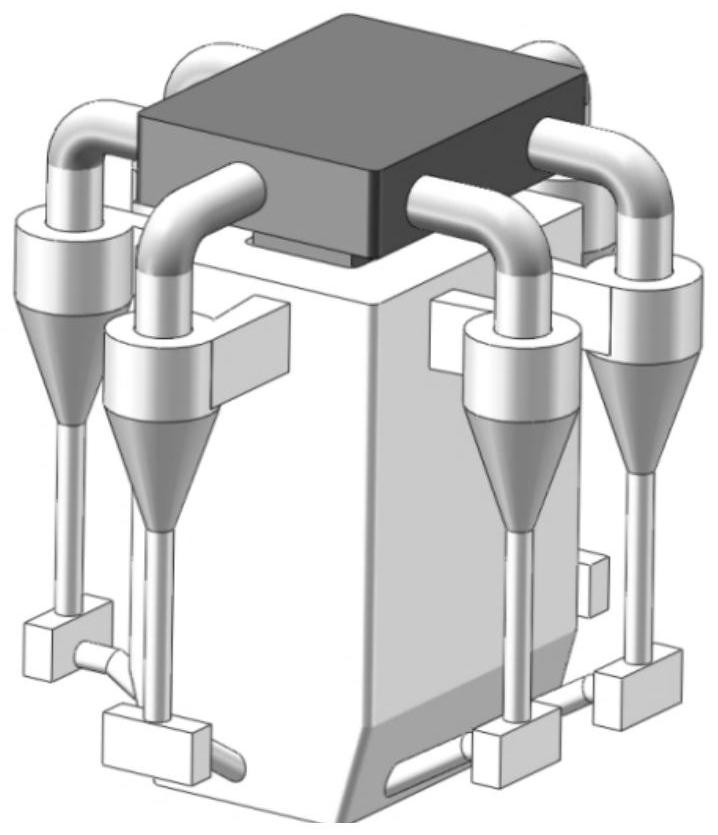

Blast furnace slag granulation and waste heat recovery system

InactiveCN113667779AEffective waste heat recoveryWaste heat recovery system, different from other slag waste heat utilizationIncreasing energy efficiencyRecycling and recovery technologiesFluidized bedProcess engineering

The invention discloses a blast furnace slag granulation and waste heat recovery system, and relates to the field of blast furnace slag waste heat recovery. The blast furnace slag granulation and waste heat recovery system comprises a blast furnace, a high-pressure slag conveying device, a slag granulation fluidized bed device, a supercritical CO2 recompression power circulation system and a low-temperature slag heat recovery device; the high-pressure slag conveying device is arranged between the blast furnace and the slag granulation fluidized bed device; the slag granulation fluidized bed device is connected with the low-temperature slag heat recovery device; and the supercritical CO2 recompression power circulation system is respectively connected with the slag granulation fluidized bed device and the low-temperature slag heat recovery device. The supercritical CO2 recompression circulation technology is introduced, meanwhile, supercritical CO2 airflow is adopted as a cooling medium, the waste heat recovery efficiency is improved, and meanwhile high-quality slag products are produced.

Owner:SOUTHEAST UNIV

A Boiler Waste Heat Heating Method Against Low Temperature Corrosion

ActiveCN105202618BMeet cooling needsAvoid Low Temperature CorrosionLighting and heating apparatusSpace heating and ventilation detailsControl flowAutomatic control

The invention provides a low-temperature corrosion resistant heating method adopting boiler residual heat. The method comprises the following steps: step I, firstly, measuring the exhaust gas temperature, and automatically adjusting the opening of a valve or the frequency of a draught fan according to the exhaust gas temperature; step II, measuring the inlet temperature of a radiator, and determining whether auxiliary heating equipment needs starting or not according to the measured temperature. According to the low-temperature corrosion resistant heating method, the inlet temperature of the radiator is automatically measured through a temperature sensor positioned at the inlet of the heating radiator, so as to meet the heat dissipation demand; the exhaust gas temperature is automatically controlled through controlling flow of exhaust gas participating in residual heat utilization and heat exchange, so that low-temperature corrosion is avoided, and intelligentized adjustment of a system is realized.

Owner:TAIYUAN BOILER GROUP +1

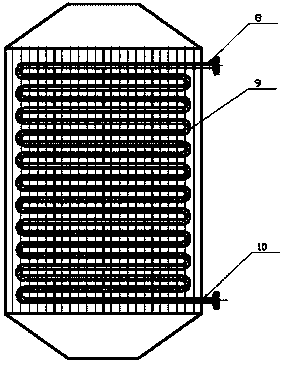

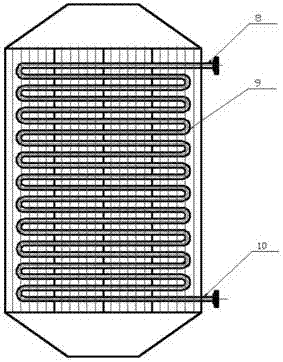

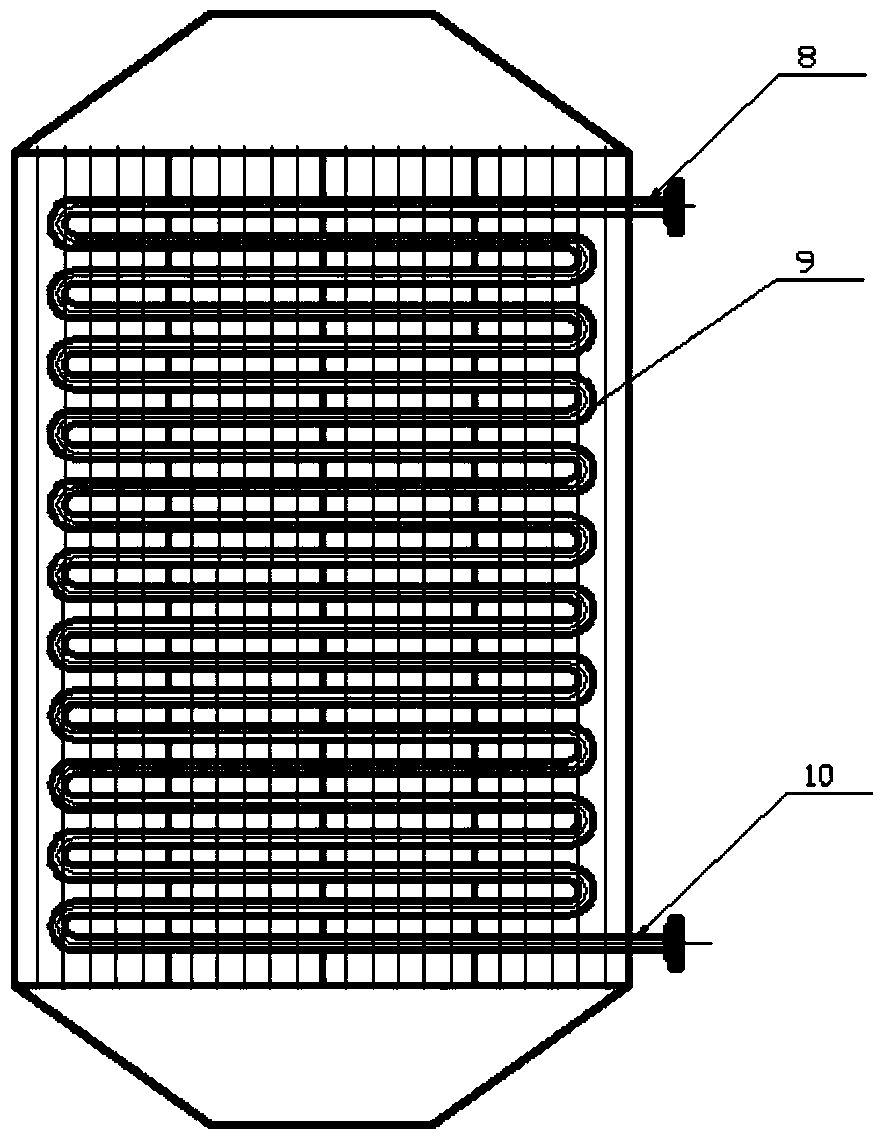

Heat accumulating type heat exchanger for waste-heat utilization during cement production process

InactiveCN103954160BIncrease profitImprove stabilityHeat storage plantsChemical industryFlue gasProcess engineering

The invention provides a heat accumulating type heat exchanger for waste-heat utilization during a cement production process. The heat exchanger comprises a first pipe bundle, a second pipe bundle, a high temperature flue gas inlet, a high temperature flue gas outlet, a low temperature working medium inlet, a low temperature working medium outlet and a housing, wherein the first pipe bundle and the second pipe bundle are arranged in the housing; the first pipe bundle is used for communicating flue gas generated during the cement production process; the second pipe bundle is used for being communicated with the low temperature medium; the first pipe bundle and the second pipe bundle are arranged in cross-connection; the flue gas enters from the high-temperature flue gas inlet, passes the first pipe bundle, and is discharged from the high temperature flue gas outlet; the low temperature medium enters from the low temperature medium inlet, passes the second pipe bundle, and is discharged from the low temperature medium; heat accumulating materials are placed in the space out of the first pipe bundle and the second pipe bundle. The heat accumulating type heat exchanger fully utilizes the waste heat during the cement production, and enables the heat exchange efficiency to the maximum, so as to save energy and achieve the goal of environmental protection and energy conservation.

Owner:山东中和热工科技有限公司

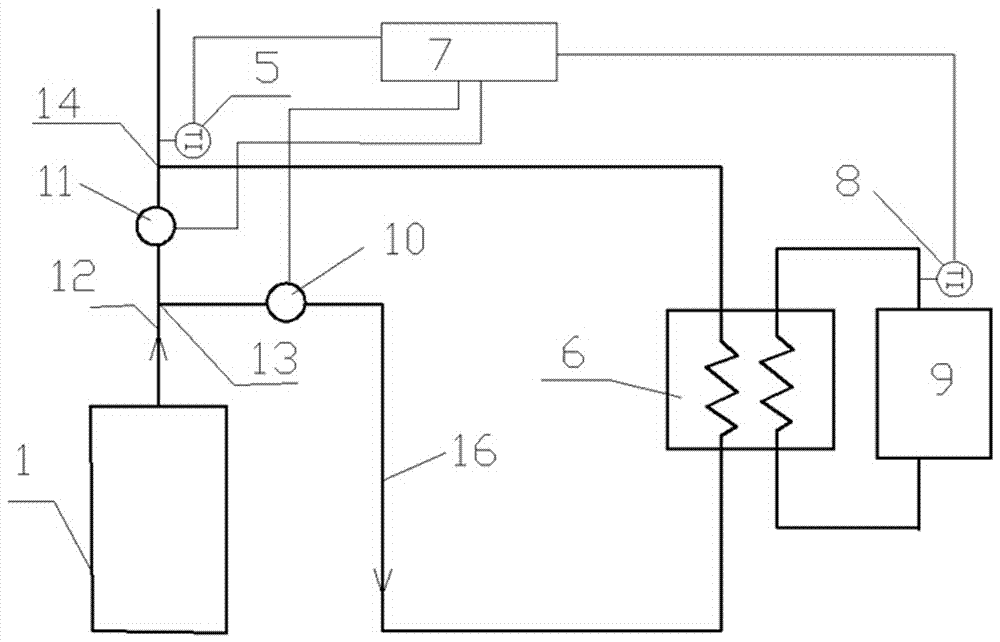

A utility boiler waste heat utilization system with auxiliary heating equipment

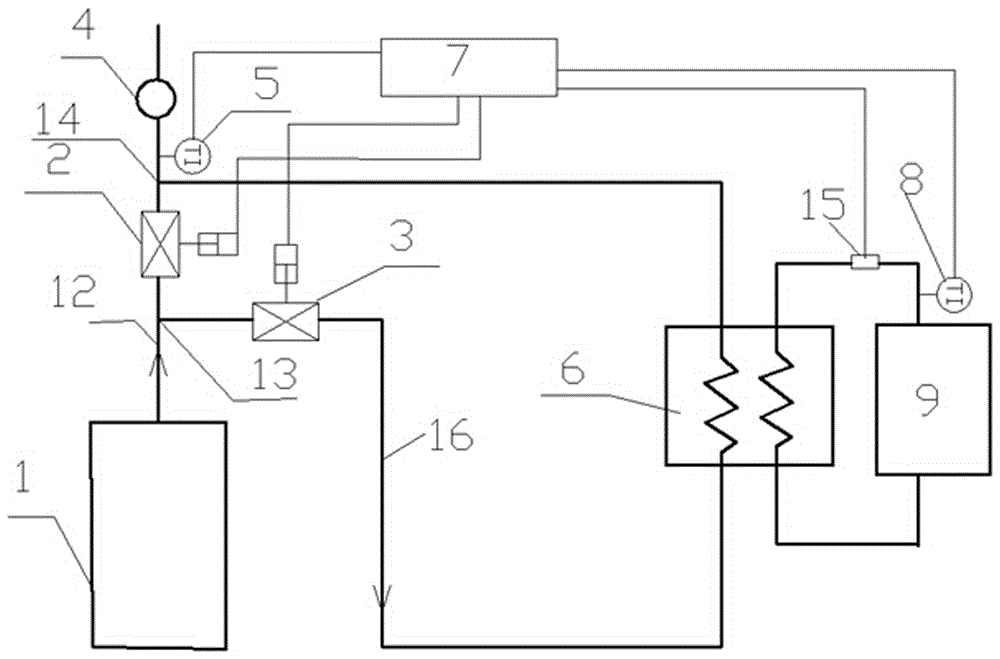

ActiveCN105202617BAvoid Low Temperature CorrosionWaste heat utilization meetsEnergy industryIncreasing energy efficiencyPlate heat exchangerFlue gas

The invention provides a utility boiler heat supply system with auxiliary heating equipment. The utility boiler heat supply system includes a boiler, a main flue, a bypass flue and a heat exchanger, wherein flue gas generated by the boiler enters the heat exchanger through the inlet of the bypass flue; flue gas subjected to heat exchange flows to the main flue through the outlet of the bypass flue and is then discharged; the heat exchanger is connected with a radiator, being a heat supply radiator; heat is transmitted to water of the radiator through flue gas in the heat exchanger, so that waste heat is utilized for heat supply; the auxiliary heating equipment is arranged on an inlet pipeline of the radiator, and is used for heating water entering the radiator. The automatic heating equipment provided by the invention can be used for automatically adjusting the heating power according to the utilization condition of waste heat, so that the heat supply effect is guaranteed, energy is saved, and intelligent adjustment of the system is realized.

Owner:TAIYUAN BOILER GROUP +1

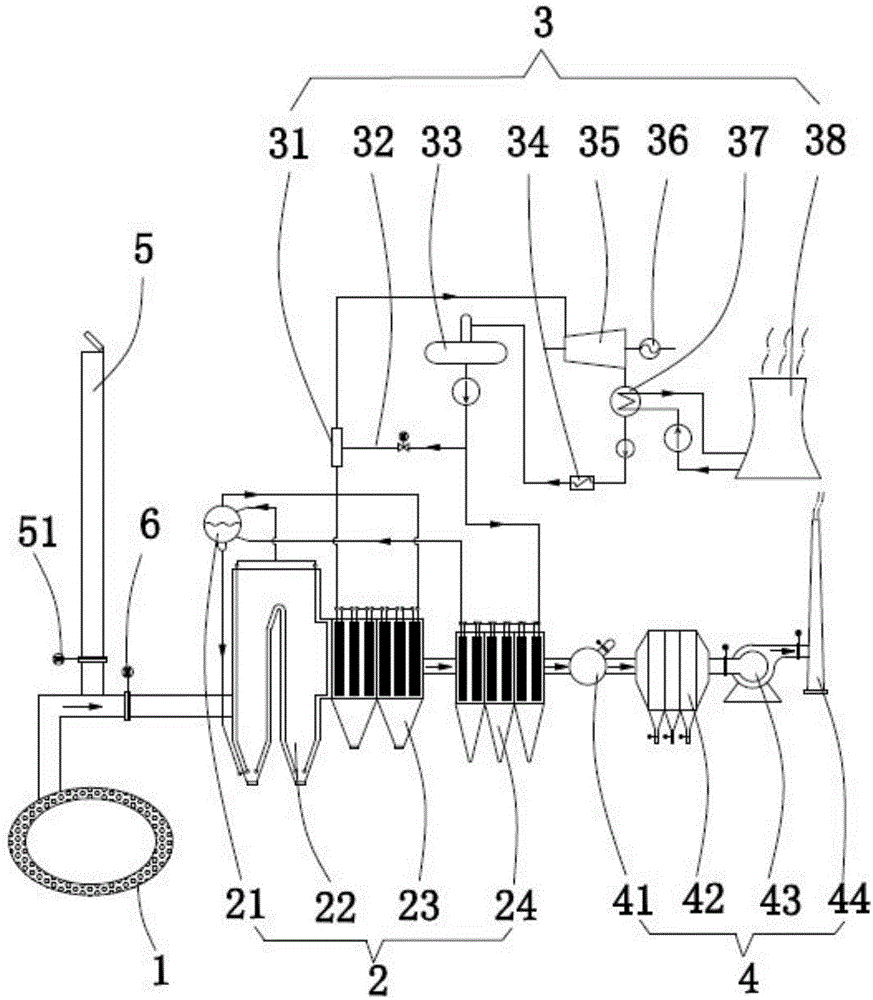

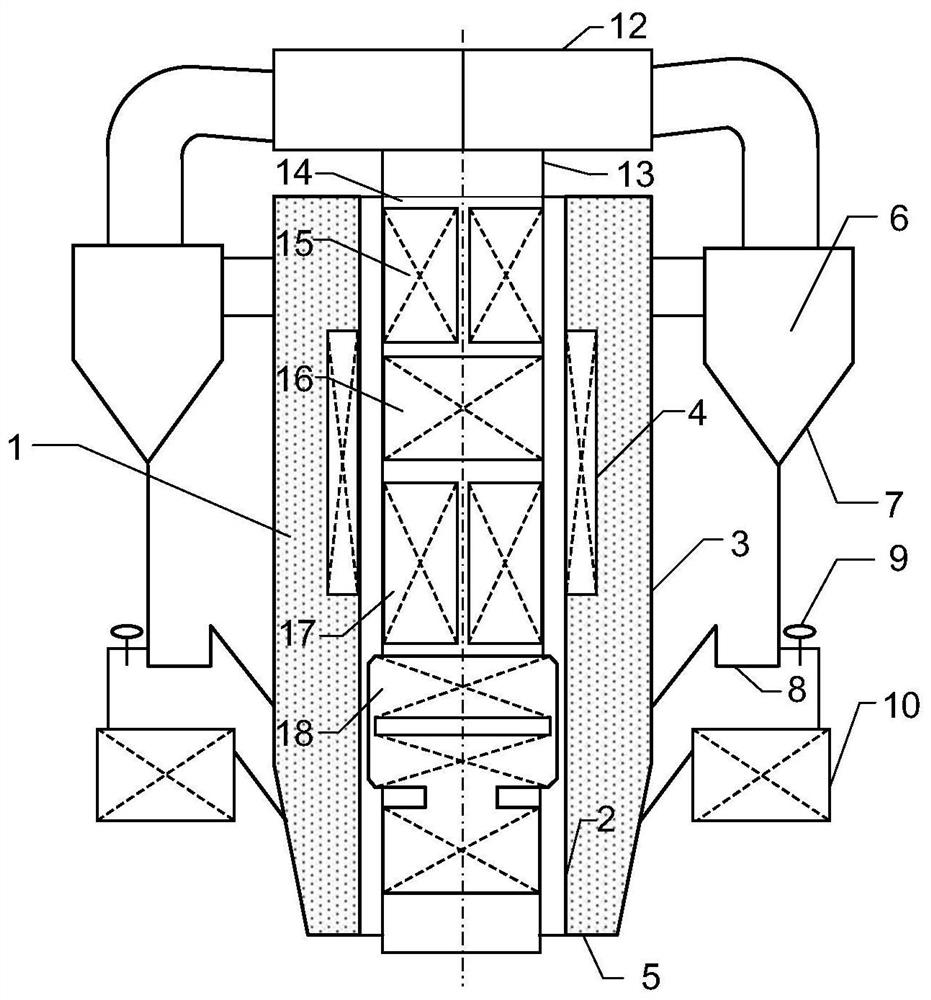

A circular circulating fluidized bed boiler with a built-in tail flue and its driving power generation system

ActiveCN110657424BAchieve compact integrationSmall footprintFluidized bed combustionMachines/enginesAir preheaterGas solid

The invention discloses a tail flue built-in loop-shaped circulating fluidized bed boiler and a driving power generation system thereof. The boiler comprises a loop-shaped hearth, a tail flue arrangedin a boiler loop-shaped inner cavity and separators symmetrically arranged with respect to the center of the hearth, wherein cold walls are uniformly distributed on an inner ring and an outer ring ofthe loop-shaped hearth, and are divided into a first region cold wall and a second region cold wall according to functional characteristics, and a flue gas mixing chamber, a low-temperature reheater,a primary air preheater, a flue gas cooler and a secondary air preheater are sequentially arranged in the tail flue in the flue gas flow direction. The boiler has the beneficial effects that the structure of the existing boiler is compact and integrated, the boiler island occupied space is reduced about one third, meanwhile, the separators which are symmetrically arranged in the center and the flue gas mixing chamber enable flue gas to be symmetrically collected, so that the uniformity of the load of the separators are effectively increased, according to the gas-solid flow state and the heatdistribution in the hearth, the side wall area and the four-corner area in the hearth the width and the deep direction are divided into heating areas with different functions, energy loss is reduced,and flexible adjustment is realized.

Owner:SOUTHEAST UNIV

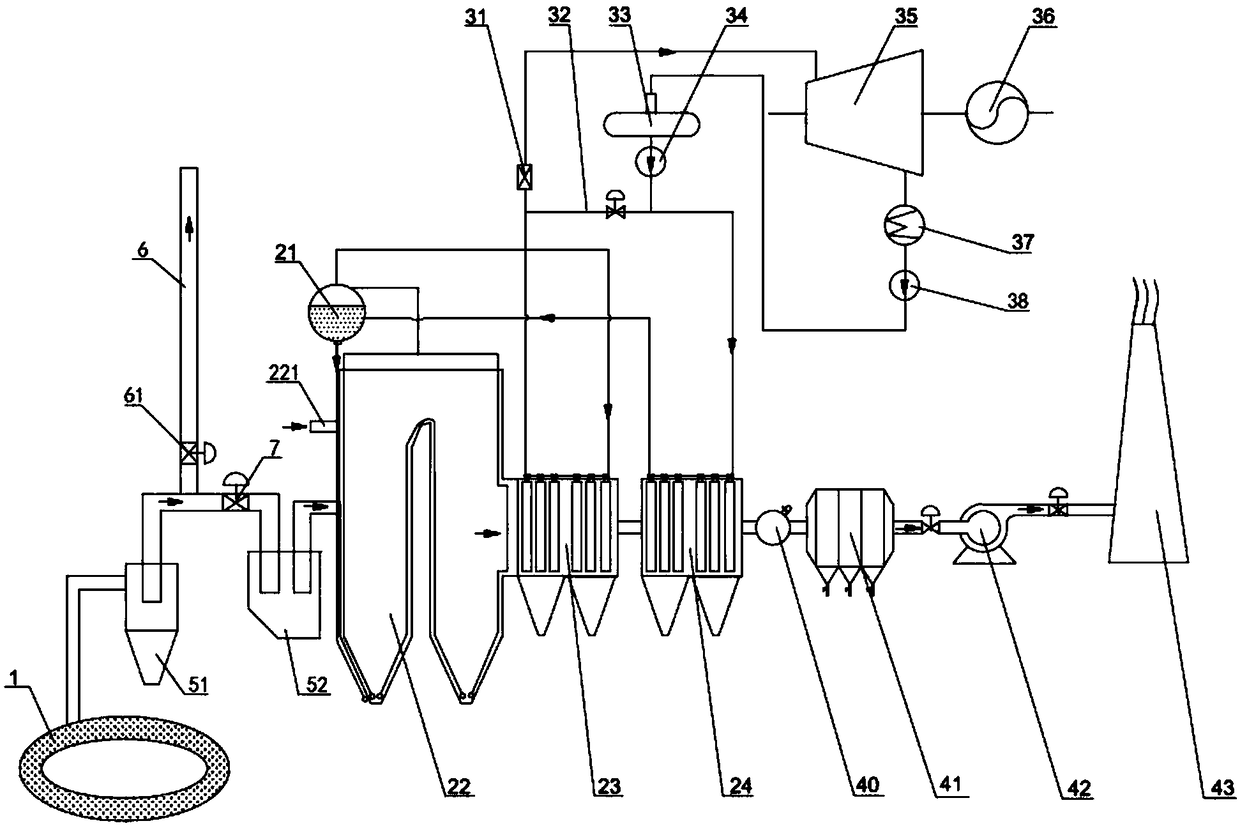

Waste heat boiler system, rotary hearth furnace high temperature dusty flue gas treatment system and method

ActiveCN106197045BAvoid dust accumulationReduce corrosionIncreasing energy efficiencyMachines/enginesFlue gasProcess engineering

The invention relates to a waste heat boiler system, a rotary hearth furnace high-temperature dust-laden smoke treatment system which is provided with the waste heat boiler system and a method for rotary hearth furnace smoke treatment applying the rotary hearth furnace high-temperature dust-laden smoke treatment system. According to the invention, an external smoke inlet is arranged on a sedimentation furnace of the waste heat boiler system, so that external high-temperature smoke is introduced in for diluting to-be-treated smoke; the dust concentration and harmful content concentration in the smoke are lowered; dust is prevented from being accumulated on the sedimentation furnace, a high-temperature heat exchange part and a low-temperature heat exchange part; the probability that smoke treatment equipment and a flue are blocked is lowered; meanwhile, corrosion of the smoke to the sedimentation furnace, the high-temperature heat exchange part, the low-temperature heat exchange part, the flue and the like is alleviated; stable operation of the waste heat boiler system and the rotary hearth furnace high-temperature dust-laden smoke treatment system is ensured; and the service life of the equipment is prolonged. Meanwhile, qualities of the smoke such as temperature can be ensured by the external high-temperature smoke, and the smoke waste heat utilization efficiency is ensured.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

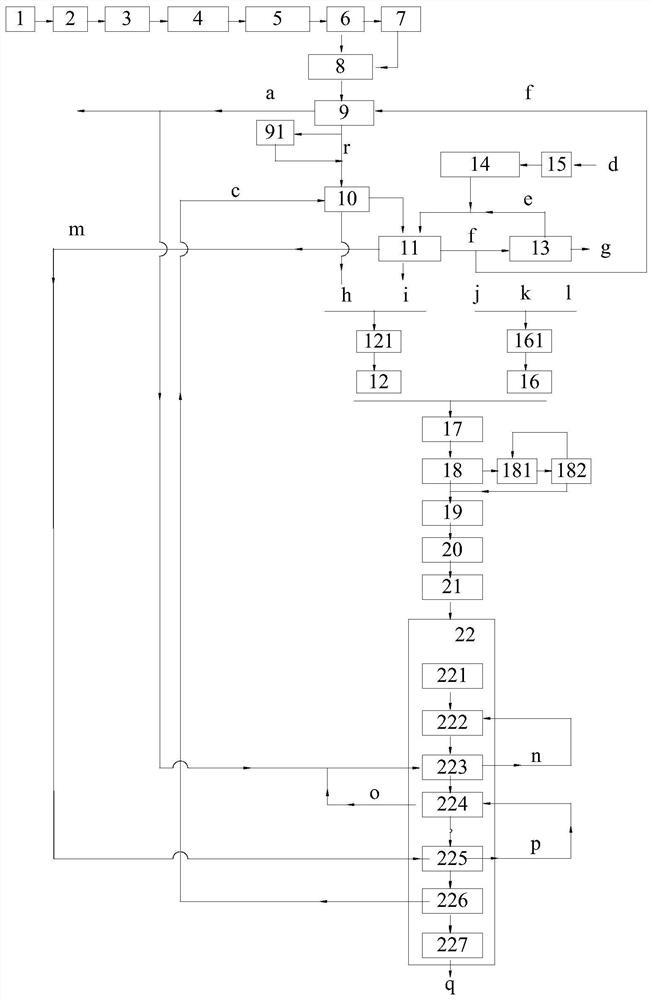

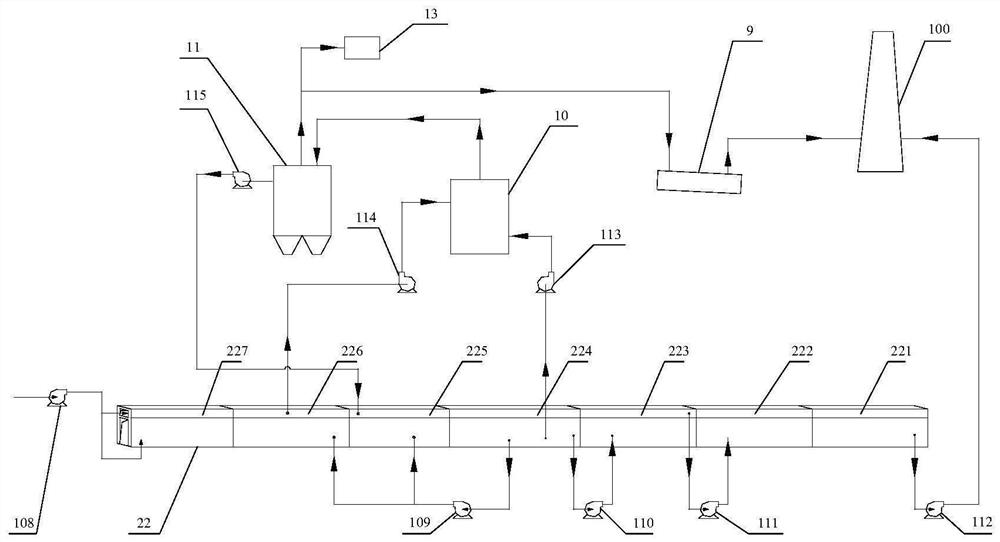

Full-process waste incineration system

PendingCN114659116ATo achieve the purification effectImprove waste heat utilization effectFurnace typesIncinerator apparatusTunnel kilnThermodynamics

The invention discloses a whole-process waste incineration system which comprises a waste pretreatment system, a waste incineration system, a waste incineration system and a waste incineration system. The waste incineration system comprises a waste incinerator (10), and a material inlet of the waste incinerator (10) is connected with a material outlet of the pretreatment drying kiln (9); the waste heat utilization system comprises a waste heat boiler (11), a flue gas inlet of the waste heat boiler (11) is connected with a flue gas outlet of the garbage incinerator (10), and a steam outlet of the waste heat boiler (11) is connected with a heat inlet of the pretreatment drying kiln (9); the waste incineration flue gas treatment system comprises a tunnel kiln (22), and the tunnel kiln (22) comprises a tunnel kiln main body structure; smoke exhausted by the waste heat boiler (11) is guided into the tunnel burning kiln body. According to the whole-process waste incineration system, the economic benefit is improved.

Owner:株洲舒创环保技术有限公司

Differential motion airtight feeding electric furnace smelting device and feeding method thereof

ActiveCN102181601BShorten the lengthIncrease the feeding speedCharge manipulationElectric furnaceHeat lossesMechanical engineering

Owner:CISDI ENG CO LTD

Steam turbine for waste heat recovery of steam boiler

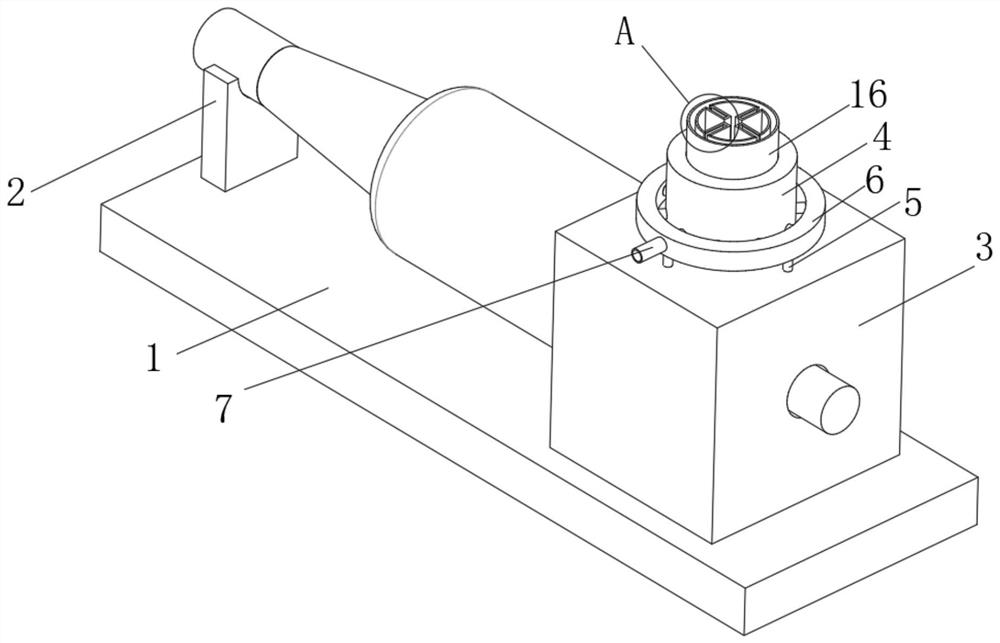

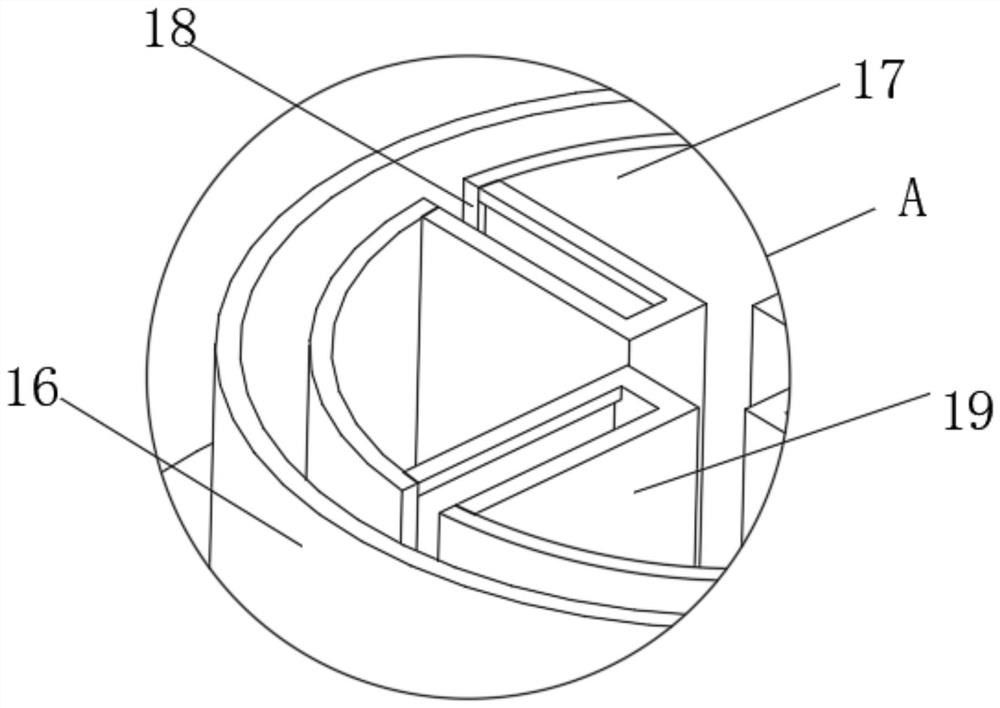

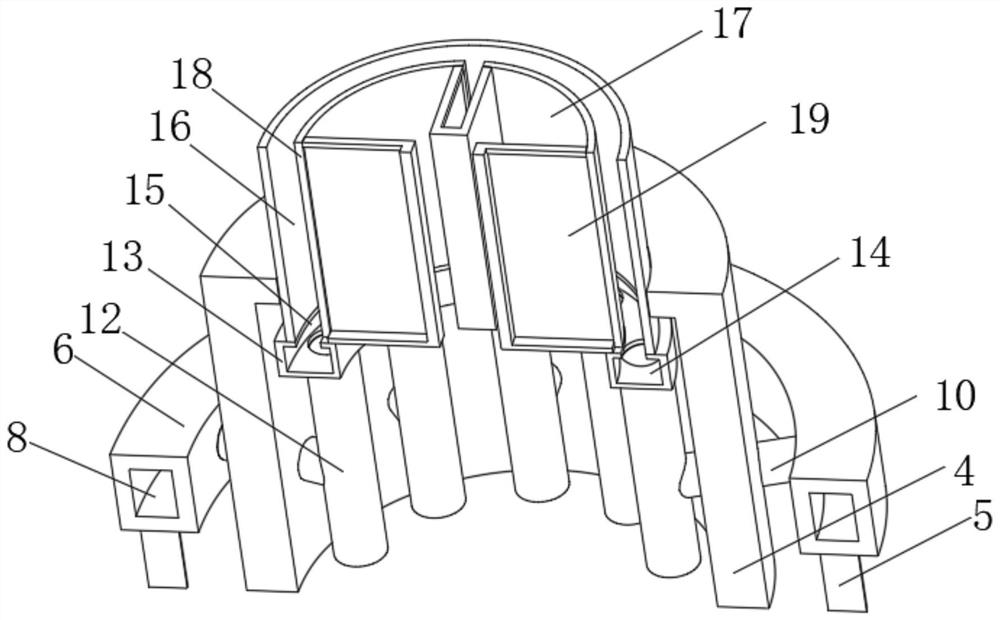

ActiveCN113464216AAvoid churnImprove absorption efficiencyMachines/enginesEngine componentsEngineeringThermal recovery

The invention relates to the technical field of steam turbines, and discloses a steam turbine for waste heat recovery of a steam boiler. The steam turbine comprises a bottom plate, wherein a steam turbine body is fixedly mounted on the top surface of the bottom plate; the top surface of the bottom plate is fixedly connected with a mounting seat positioned on the bottom surface of the front end of the steam turbine body; the bottom surface of the steam turbine body fixedly communicates with an exhaust box; a fixing rod is fixedly connected to the top surface of the steam turbine body; and a lantern ring is fixedly connected to the top surface of the fixing rod. According to the steam turbine for waste heat recovery of the steam boiler, the lantern ring is additionally arranged on the outer side surface of the exhaust box, and a communicating pipe fixedly communicates with the inner side surface of the lantern ring, so that the communicating pipe penetrates through the exhaust box and communicates with a vertical pipe in the exhaust box; and cooling water is input to the outer side of the lantern ring, the cooling water can absorb exhaust heat from the interior of the exhaust box, and heat in the exhaust box is prevented from being lost to the outside through the side surface of the exhaust box, so that the exhaust heat absorption efficiency is improved, and the use effect is good.

Owner:湖南湘化机汽轮机有限公司

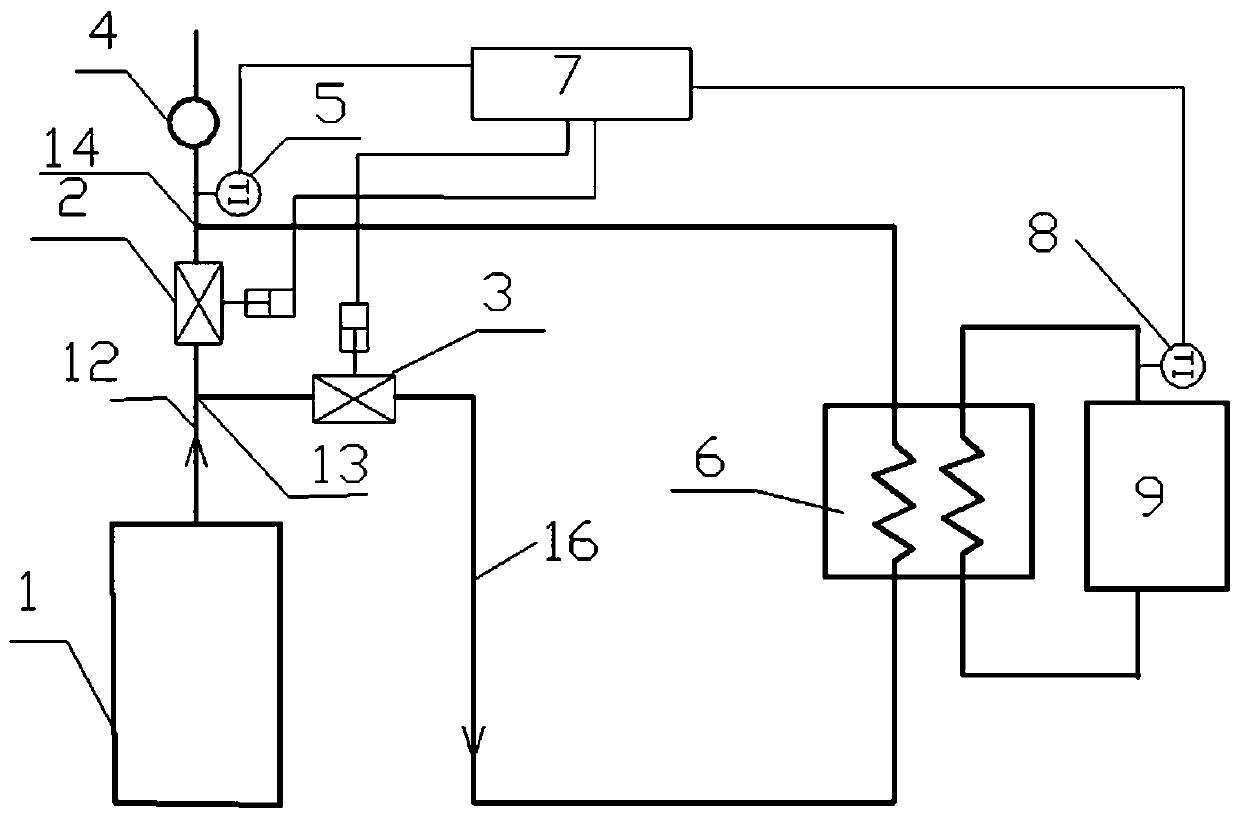

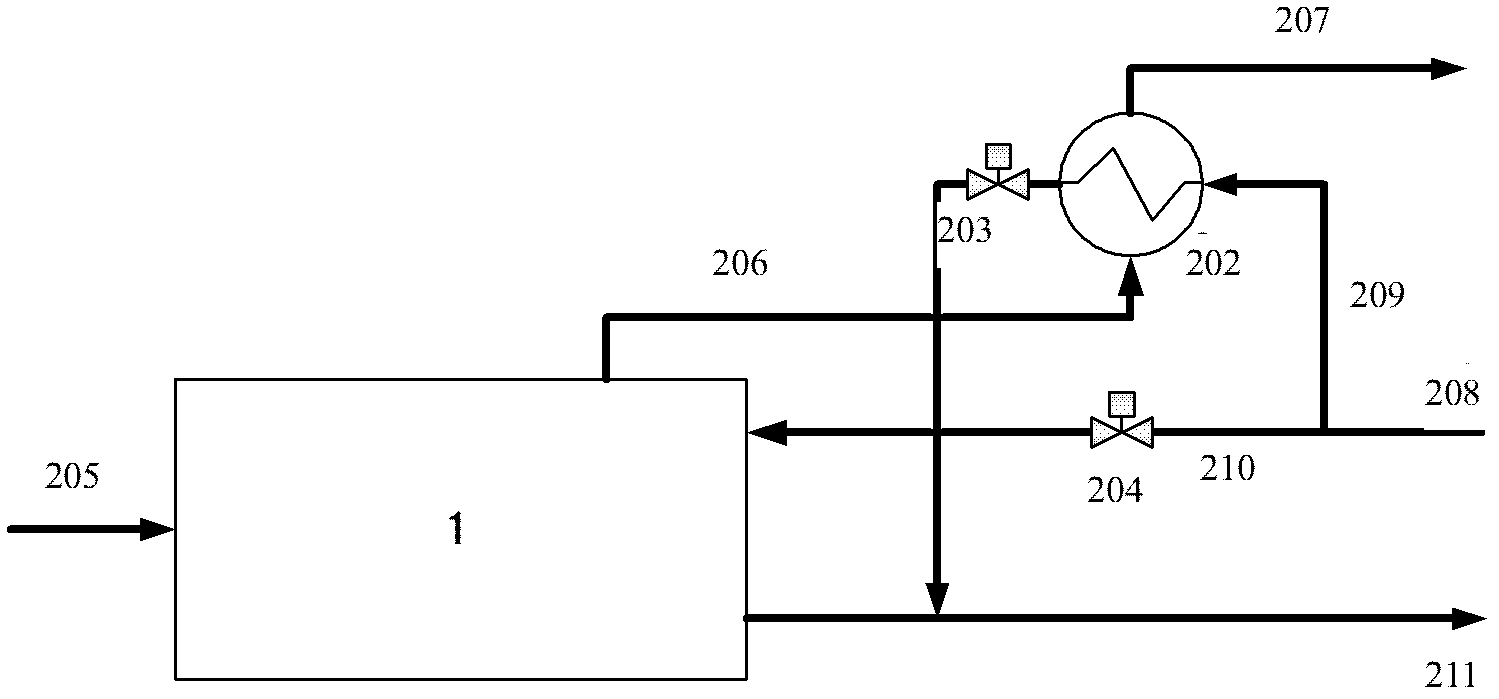

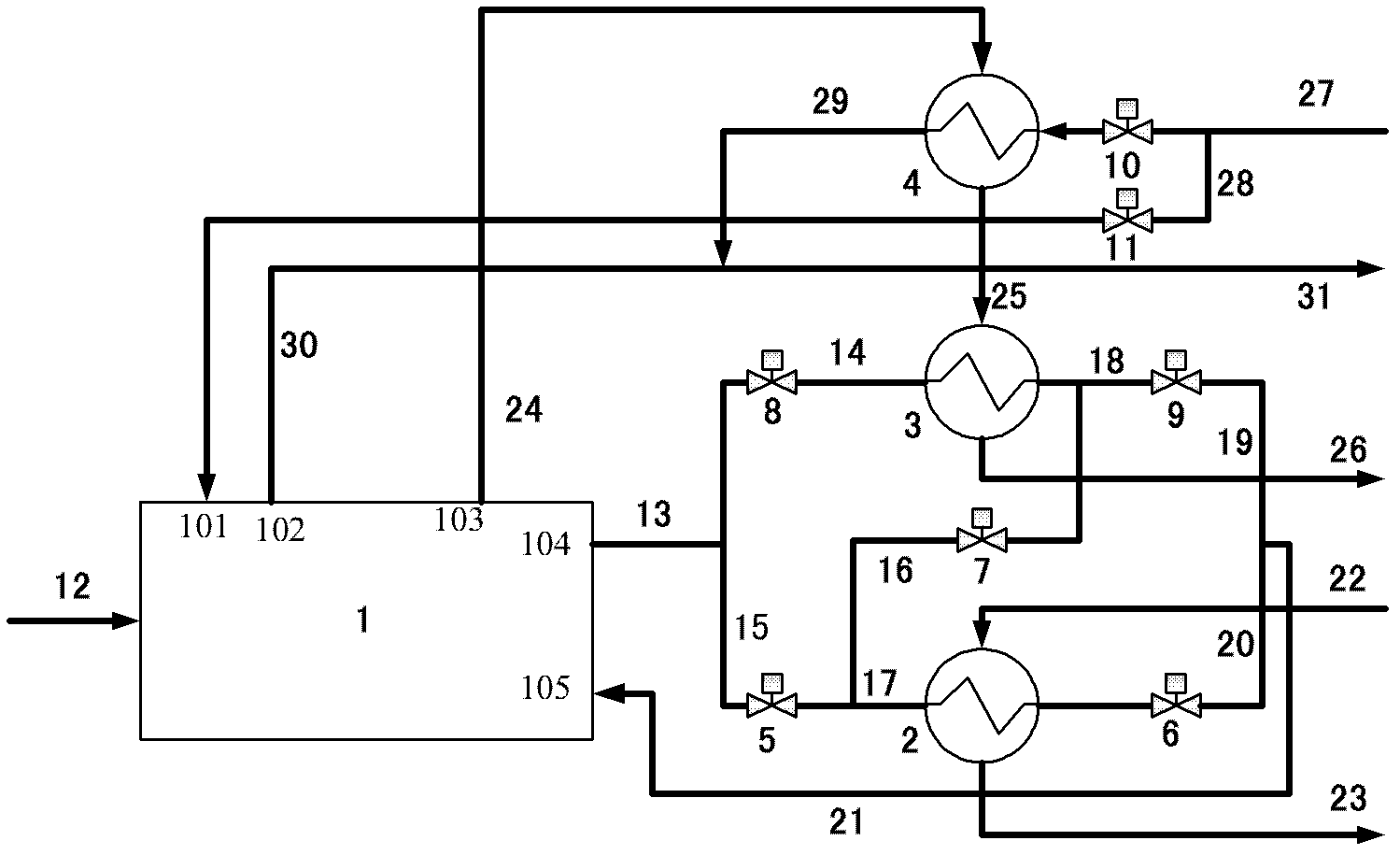

Method and device utilizing low-grade waste heat

InactiveCN103185414AEfficient use ofImprove economyMechanical apparatusEnergy efficient heating/coolingGas heaterChilled water

The invention provides a method utilizing low-grade waste heat. The method comprises the following steps: smoke emitted by an absorption type direct-fired machine is introduced into a gas-gas heater to be subjected to sensible heat recovery; the smoke subjected to the sensible heat recovery is introduced into a smoke condensation type heat exchanger to be subjected to the latent heat recovery; the smoke subjected to latent heat recovery is emitted, the absorption type direct-fired machine is in operation in a cooling season mode in heating; and sensible heat recovered is transferred to hot water discharged from a circulating heating water outlet of the absorption type direct-fired machine, and the latent heat recovered is transferred to cool water discharged from the circulating heating water outlet of the absorption type direct-fired machine. The invention further provides a device utilizing low-grade waste heat, which comprises the absorption type direct-fired machine, a heating water input branch circuit, a heating water output branch circuit, a smoke heat exchanger and the smoke condensation type heat exchanger; the heating water input branch circuit is connected with a circulating heating water inlet, and the heating water output branch circuit is connected with the circulating heating water outlet; the smoke heat exchanger is used for sensible heat recovery to the smoke emitted from a smoke outlet of the absorption type direct-fired machine; and the smoke condensation type heat exchanger is used for latent heat recovery to the smoke subjected to sensible heat recovery. The method can improve the heat utilization rate of the direct-fired machine.

Owner:ENN SCI & TECH DEV

A methanol-high pressure oxygen compound two-stroke engine and its control method

ActiveCN111287847BRealize work cycleReduce power consumptionElectrical controlInternal combustion piston enginesExhaust valveInlet valve

The invention discloses a methanol-high-pressure oxygen composite two-stroke engine, which is composed of one or more than one cylinder group, each cylinder group includes a main cylinder and a corresponding auxiliary cylinder, the main cylinder is provided with a starting fuel nozzle, The methanol nozzle, the oxygen nozzle and the exhaust valve of the main cylinder do not have an intake valve. There is a connecting channel between the exhaust port of the main cylinder and the auxiliary cylinder. The connecting channel has a one-way valve at the entrance of the auxiliary cylinder. The one-way valve can only The gas in the main cylinder flows into the auxiliary cylinder. The auxiliary cylinder does not have a fuel nozzle, but is equipped with an inlet valve of the auxiliary cylinder and an exhaust valve of the auxiliary cylinder. Control the amount of oxygen injected by the main cylinder, control the degree of fuel combustion, introduce the high-temperature active gas that has not been completely burned in the main cylinder into the auxiliary cylinder to continue burning, realize the cycle of separate cylinders, reduce the emission of harmful gases, and realize the full combustion of fuel.

Owner:ANYANG INST OF TECH

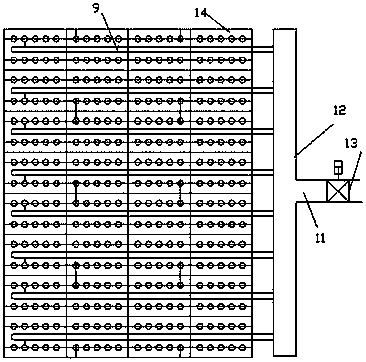

Multistage flash system with intermediate heat accumulation

ActiveCN103925820BAvoid corrosionIncrease profitIncreasing energy efficiencyRegenerative heat exchangersMulti-stage flash distillationEngineering

The invention provides a heat accumulation type heat exchanger for utilizing waste heat in the cement production process. The heat exchanger comprises heat accumulation material, first holes and second holes are formed in the heat accumulation material and are of multi-row structures, a row of second holes are arranged between every two rows of first holes, a row of first holes are arranged between every two rows of second holes, the first holes and the second holes are arranged to form an angle of 90 degrees, the distance between the centers of circles of every two adjacent holes in the same row of first holes is L2, and L2 and the diameter D1 of the first holes meet the relation that 1.5<L2 / D1<2.7. According to the solid material heat accumulation type heat exchanger, waste heat in the cement production process is fully utilized so that the heat exchange efficiency of the heat exchanger can be maximized, and thus energy is saved, and the purposes of environmental protection and energy conservation can be achieved.

Owner:山东中和热工科技有限公司

A boiler heating system

ActiveCN105387505BEfficient use ofAvoid Low Temperature CorrosionHeat exhanger finsSpace heating and ventilation detailsProcess engineeringEngineering

The invention provides a boiler heat supply system. The system comprises a boiler, a main flue, a bypass flue and a heat exchanger. Smoke generated by the boiler enters the heat exchanger through an inlet of the bypass flue. The smoke subjected to heat exchange flows into the main flue to be exhausted after passing an outlet of the bypass flue. The heat exchanger is connected with a radiator which is a heating radiator. The smoke in the heat exchanger transmits heat to water of the radiator, and waste heat can be utilized for heat supply. According to the novel boiler waste heat supply system, utilization of the waste heat of smoke of the boiler is guaranteed, and energy is saved.

Owner:TAIYUAN BOILER GROUP +1

Drainage waste heat utilization system of power station boiler

PendingCN114484410AImprove waste heat utilization effectAccurate entryBoiler cleaning apparatusPower stationEnvironmental engineering

The drainage waste heat utilization system of the power station boiler comprises a water collecting tank and multiple sets of water outlet and return devices, each water outlet and return device comprises a water outlet mechanism and a water return mechanism, the water outlet mechanism comprises a water outlet mechanism arranged on a drainage tank, and the water return mechanism comprises a water inlet pipe connected to a water cooling wall. The water outlet mechanism and the water collecting tank are used for inputting drained water into the water inlet pipe of the other water outlet and return device. The method has the effect of improving the drainage waste heat utilization effect.

Owner:温州宏泽热电股份有限公司

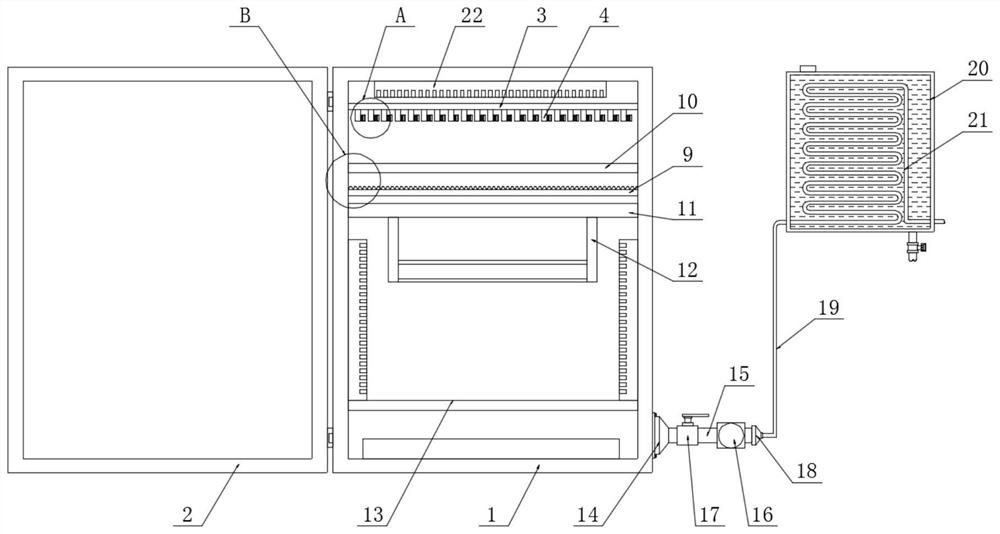

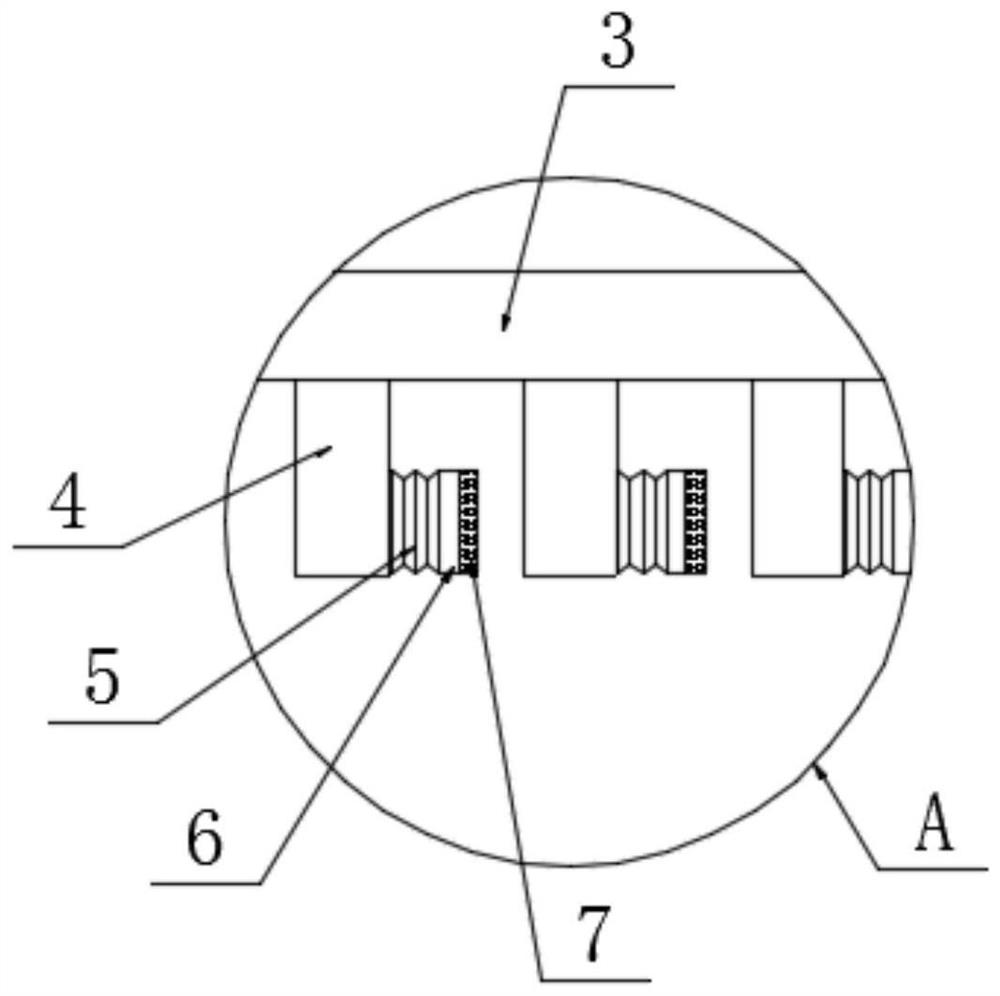

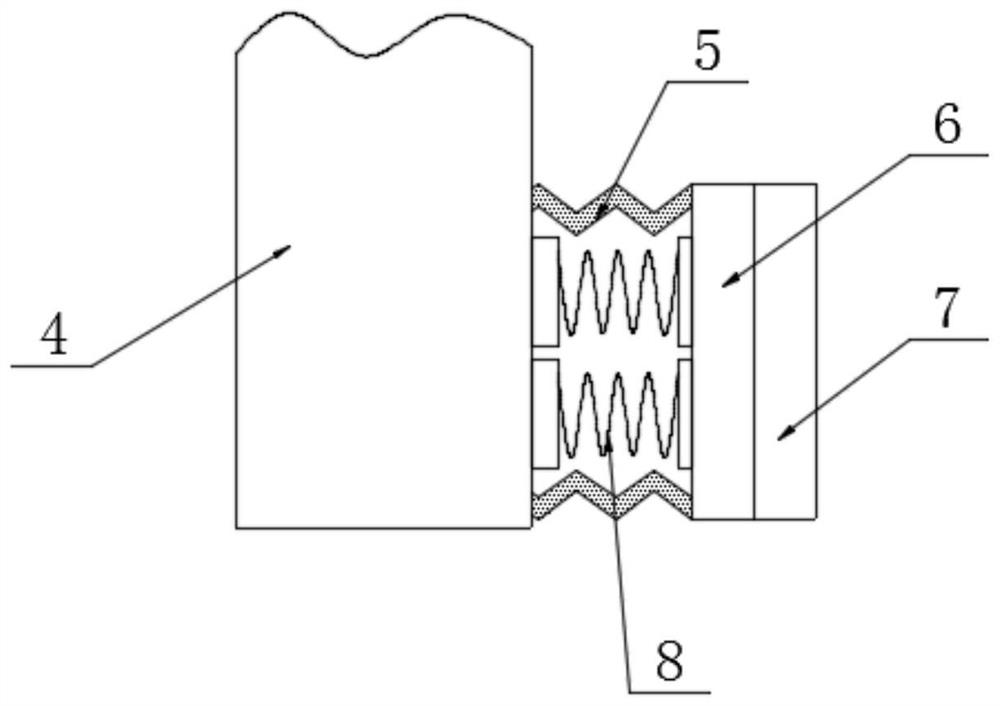

A household tableware disinfection cabinet

The embodiment of the present invention discloses a household tableware disinfection cabinet, specifically related to the field of household electrical appliances, including a disinfection cabinet body, a first fixing frame is installed on the top inner wall of the disinfection cabinet body, and the bottom of the first fixing frame is along the horizontal Several clamping mechanisms are equidistantly installed in the direction. The clamping mechanism is composed of a fixed block, a protective cover, a push plate, a cotton cloth layer and a first spring. The fixed block is fixedly connected to the bottom of the first fixed frame, and the fixed The outer wall of the bottom of the block is connected with a protective cover, one end of the protective cover is connected with a push plate, the outer wall of the push plate is provided with a cotton cloth layer, and the inner wall of the push plate is located inside the protective cover and connected with a first spring. The invention can conveniently place and limit the position of the dinner plate, avoid the slipping of the dinner plate caused by the inclination of the disinfection cabinet during the movement process, and improve the effect of waste heat utilization. Bacterial growth and mildew caused by time storage will affect the health of users.

Owner:WENZHOU UNIV OUJIANG COLLEGE

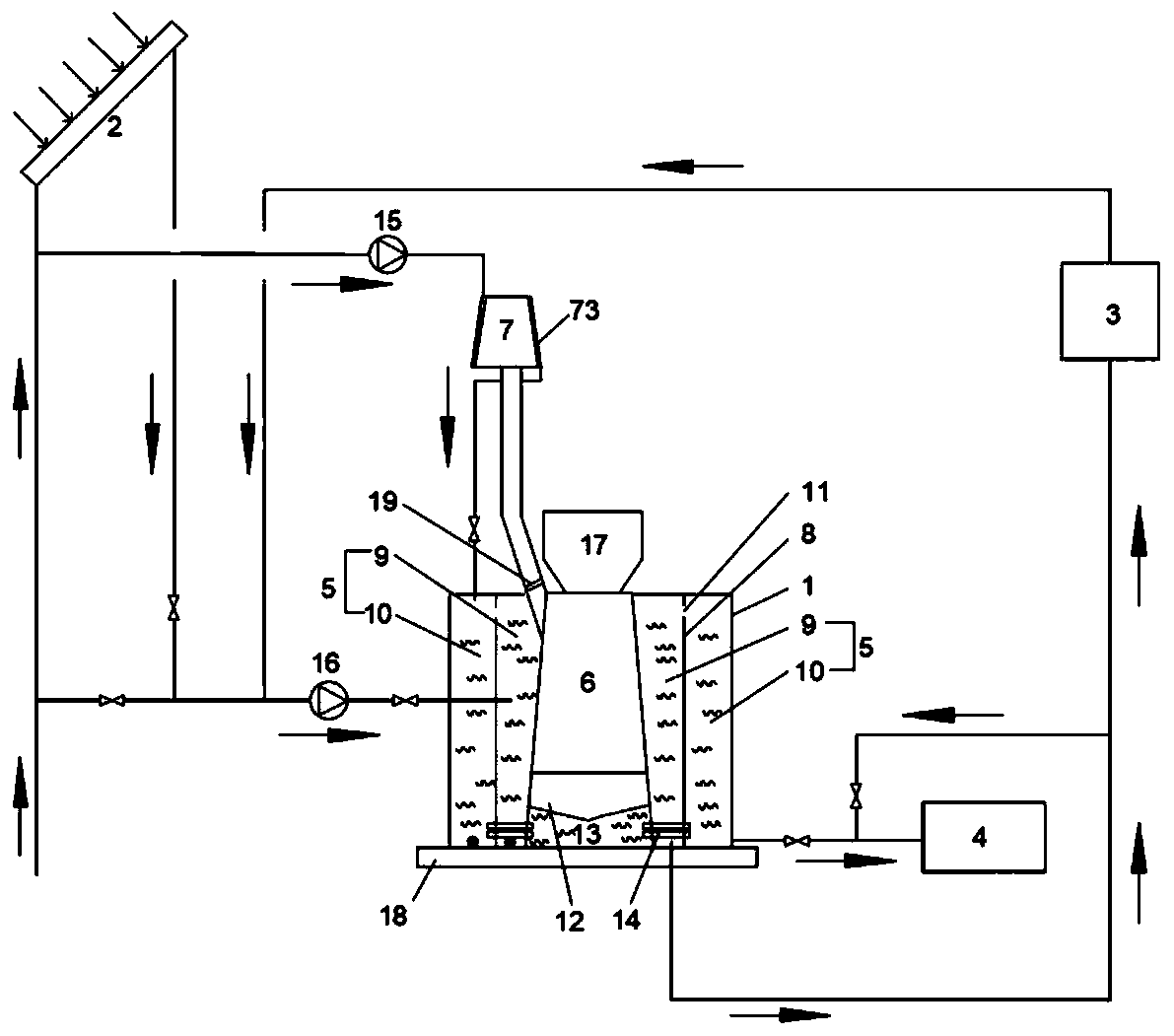

Small biomass heat supply system for transforming traditional cooking bench

ActiveCN110173719AFully absorbedKeep the basic lookSolar heating energyStove/ranges for heating waterWater flowEngineering

The invention relates to the technical field of biomass boilers, in particular to a small biomass heat supply system for transforming a traditional cooking bench. The small biomass heat supply systemcomprises a cooking bench, a solar thermal collector, a heat radiator and domestic water equipment, wherein the cooking bench comprises a water tank, a hearth and a chimney, a water tank is arranged on the outer wall of the hearth, a partition plate is arranged in the water tank and divides the water tank into an inner water tank and an outer water tank, a water flow channel is formed in the wallsurface of the chimney, water in the water flow channel exchanges heat with smoke in the chimney, an water inlet of the solar thermal collector is connected with the municipal water supply, a water outlet of the solar thermal collector communicates with a water inlet of the inner water tank, and a water outlet of the inner water tank communicates with a water inlet of the heat radiator; and a water inlet of the water flow channel is connected with the municipal water supply, a water outlet of the water flow channel communicates with a water inlet of the outer water tank, a water outlet of theouter water tank communicates with a water inlet end of the domestic water equipment. The inner water tank and the outer water tank are arranged on the outer wall of the hearth, so that hot water canbe provided for heating and hot water for life can be provided as well.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A small biomass heating system

ActiveCN110173719BFully absorbedKeep the basic lookSolar heating energyStove/ranges for heating waterWater useHearth

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com