A methanol-high pressure oxygen compound two-stroke engine and its control method

An engine and compound technology, applied in the direction of engine control, electrical control, combustion engine, etc., can solve the problems of latent heat of vaporization of soot emissions, and the waste heat of engine exhaust gas is not efficiently utilized, so as to improve the thermal efficiency of work and realize the EGR rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

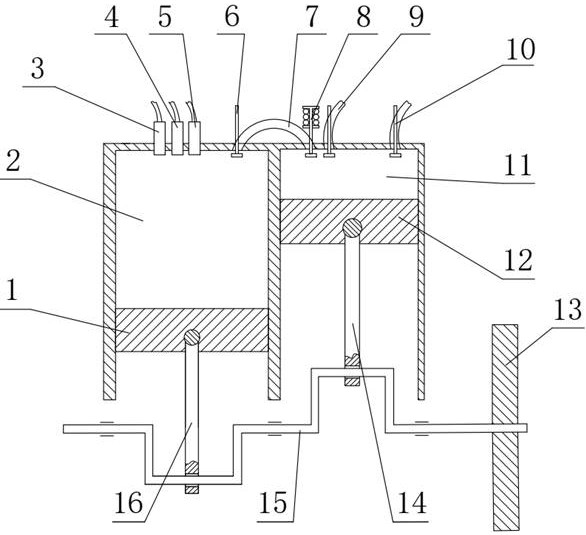

[0064] Below, comprehensive reference figure 1 The methanol-high pressure oxygen compound two-stroke engine of the present invention will be described in detail.

[0065] like figure 1 As shown, in the methanol-high-pressure oxygen composite two-stroke engine of the present invention, there is a cylinder group composed of a crank connecting rod mechanism, a gas distribution mechanism and a fuel supply system, a lubrication system, a cooling system, a starting system, and an oxygen injection system And ECU (control unit); wherein, the cylinder group is composed of a main cylinder 2 and an auxiliary cylinder 11.

[0066] like figure 1 As shown, in the methanol-high pressure oxygen composite two-stroke engine of the present invention, the main cylinder 2 is provided with a starting fuel nozzle 4, a methanol nozzle 3, an oxygen nozzle 5 and a main cylinder exhaust valve 6, and no intake valve , There is a connecting passage 7 between the main cylinder 2 and the auxiliary cylind...

Embodiment 2

[0107] The methanol-high-pressure oxygen composite two-stroke engine of the present invention is composed of two groups of identical cylinder groups, the main cylinder piston in the first cylinder group and the master cylinder piston in the second cylinder group have a working phase difference of 180°CA, and the starting fuel adopts dimethicone Ether; such as figure 1 As shown, it is a cylinder group in the cylinder group of the engine. Its valve mechanism adopts variable valve timing technology, and the number of exhaust valves in the main cylinder is two, so as to increase the exhaust volume of the main cylinder and shorten the exhaust time. . The control method of this engine is basically the same as that of Example 1, but it can automatically adjust the crankshaft angle corresponding to the opening and closing of the intake valve of the main cylinder according to the engine speed, load, and temperature changes, and automatically adjust the intake valve and exhaust of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com