Reciprocating grate of small biomass boiler

A biomass boiler and reciprocating grate technology, applied in the direction of grate, mobile grate, combustion method, etc., can solve the problems of boiler black smoke, grate can not be cooled well, increase labor intensity, etc., to improve combustion Efficiency, good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

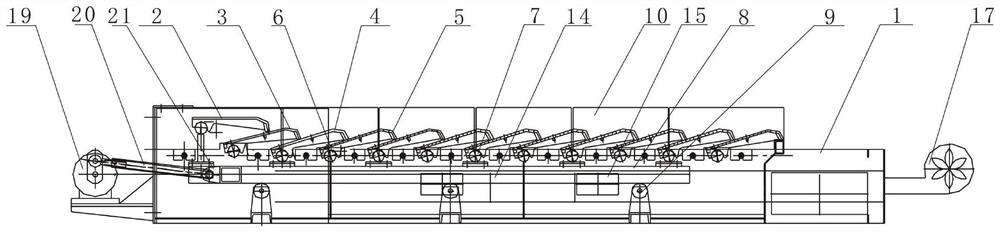

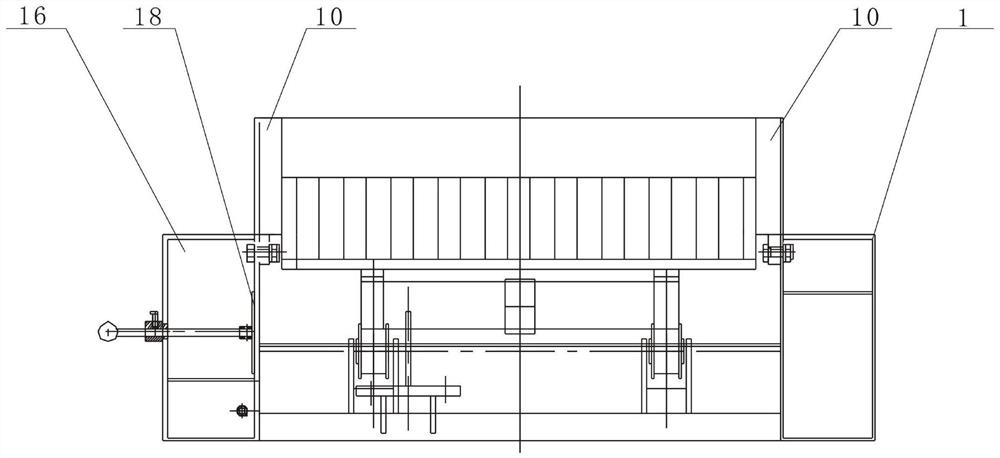

[0042] Such as Figure 1-Figure 11 As shown, a reciprocating fire grate of a small biomass boiler in the present invention includes: a base 1, a fire grate, a fire grate fixed beam 6, a movable steel frame, a supporting wheel device 9, an air supply device, a transmission device, and a sealing iron 10.

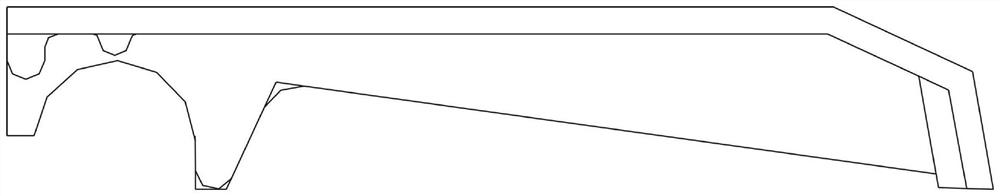

[0043] The base 1 includes a lower bottom plate and two side plates vertically connected above both sides of the lower bottom plate.

[0044] The grate includes a pusher grate and a combustion grate. The pusher grate is installed under the boiler feeding device at the front end, and the combustion grate is installed under the boiler furnace at the rear end. That is, in this embodiment, the biomass fuel is defined as The direction of travel on the grate is from front to back. The rear end of the combustion grate is provided with an ash box for receiving ashes.

[0045] Such as figure 1 As shown, the pusher grate is composed of a movable pusher grate 2 and a fixed pusher grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com