Steam boiler combusting biomass gas

A steam boiler and material technology, applied in steam boilers, water tube steam boilers, non-flammable liquid/gas transportation, etc., can solve the problems of poor stability and low thermal efficiency of boilers, and achieve strong load regulation ability and large heat transfer area , Adapt to the effect of rapid load changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

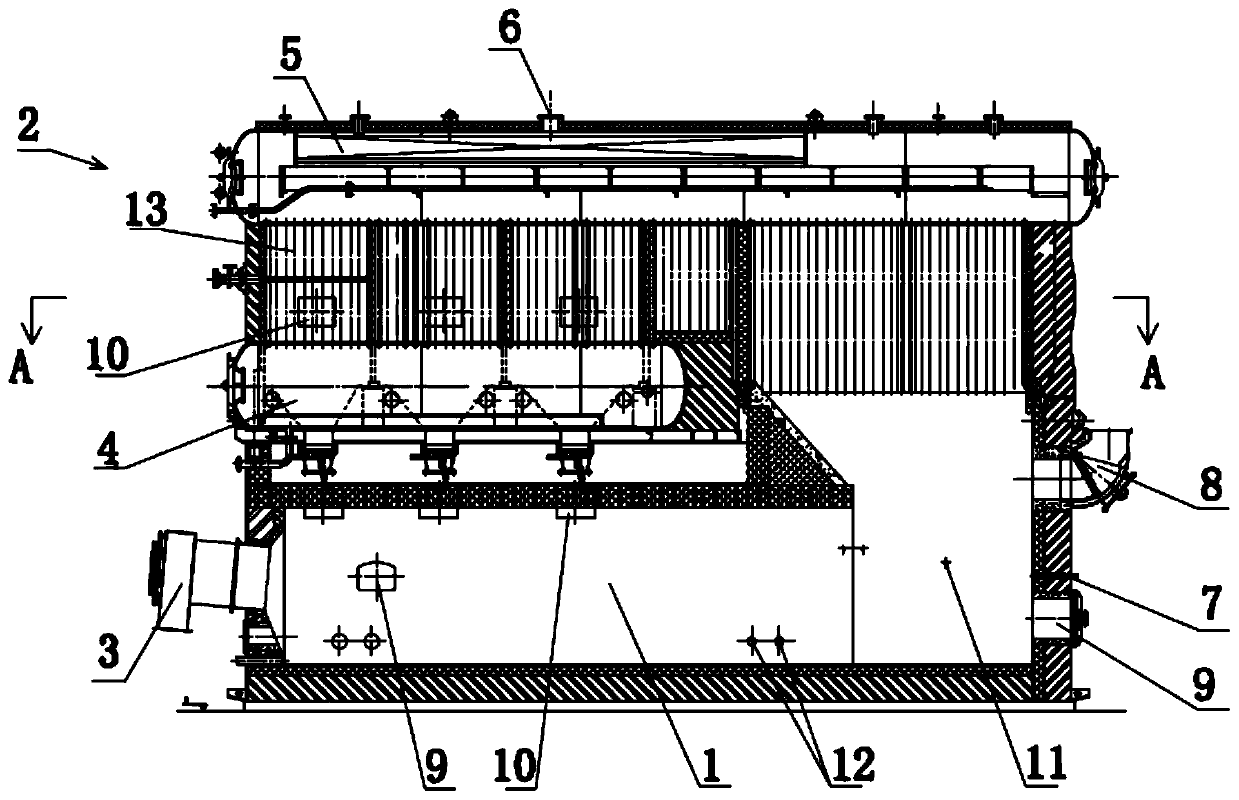

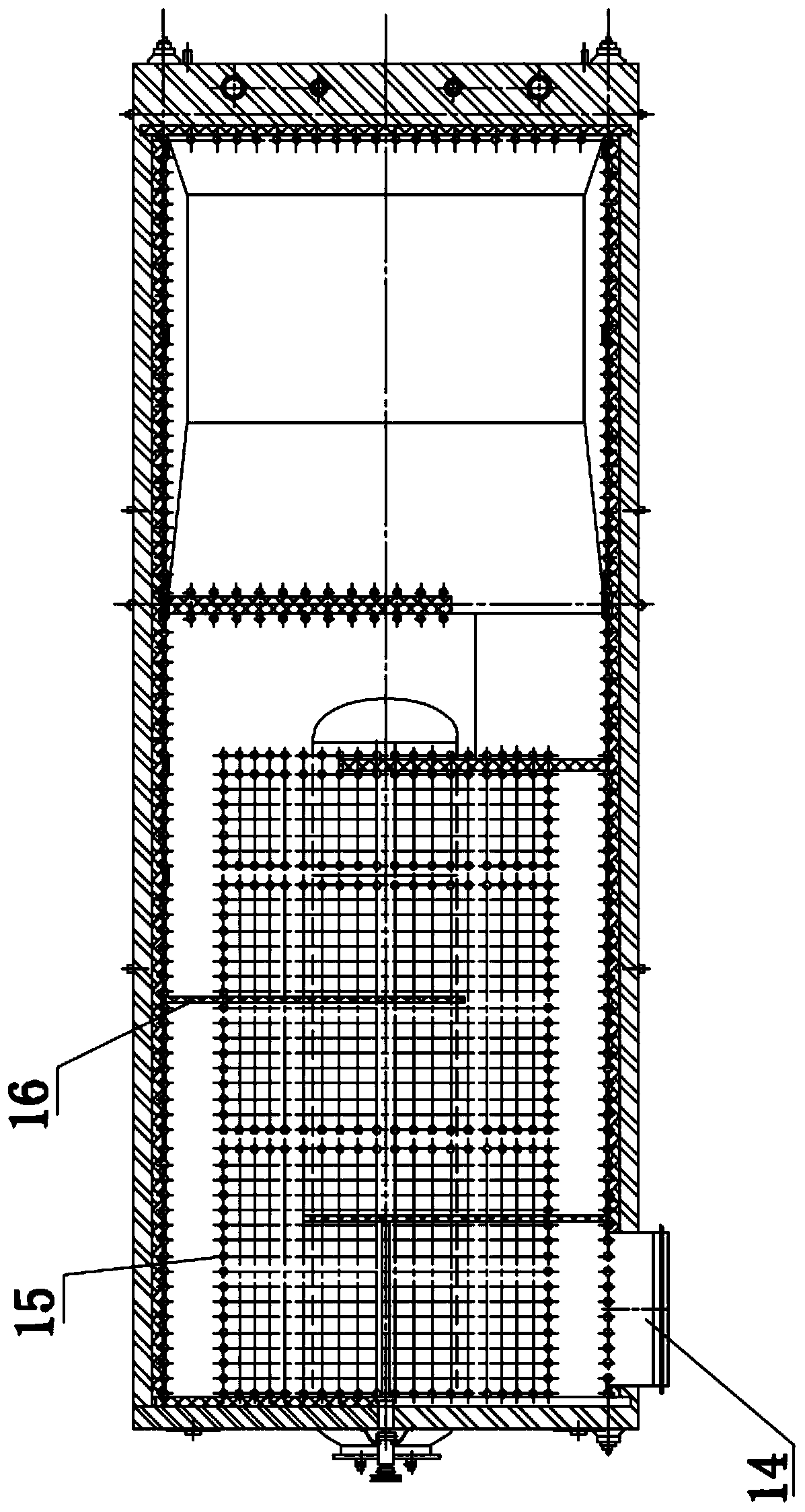

[0030] The specific embodiment of the present invention is as Figure 1 to Figure 2 As shown, a biomass gas-burning steam boiler includes a boiler body 2 and a combustion chamber 1 respectively arranged up and down, and the boiler body 2 includes a smoke exhaust channel 13 communicating with the combustion chamber 1 and a drum for filling water , The smoke exhaust channel 13 is provided with a smoke exhaust port 14, and the smoke exhaust port 14 is located on the upper side wall of the front end of the boiler body 2. The boiler drum is located on the upper and lower sides of the smoke exhaust channel 13, and a large number of water-cooled wall pipes 15 communicating with the drum are arranged in the smoke exhaust channel 13, and a steam outlet 6 is arranged on the upper side of the drum. A biomass gas burner 3 is installed at the gas inlet end of the combustion chamber 1, and the burner 3 is located on the furnace wall at the front end of the combustion chamber 1 of the boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com