Straw bundle burning direct-fired biomass boiler with bale breaking and material stirring device

A biomass boiler and straw bale technology, which is applied in the field of straw bale burning, can solve the problems of insufficient combustion of straw bale, incomplete combustion, slow burning speed, etc., achieves complete and complete combustion, solves the problem of direct combustion, and prolongs the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

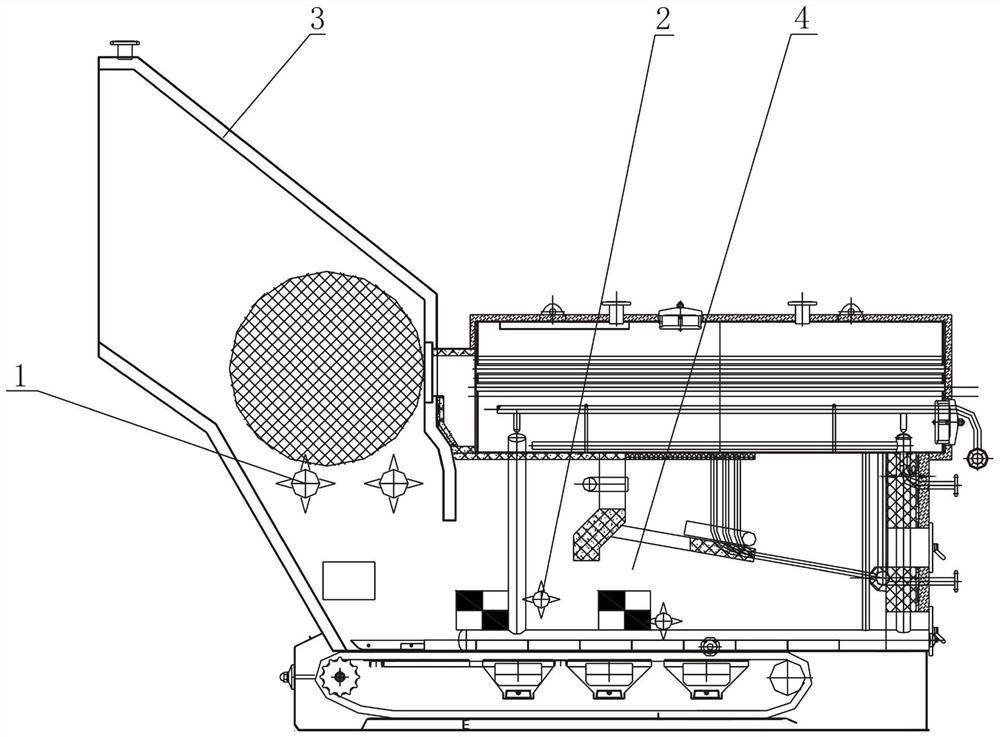

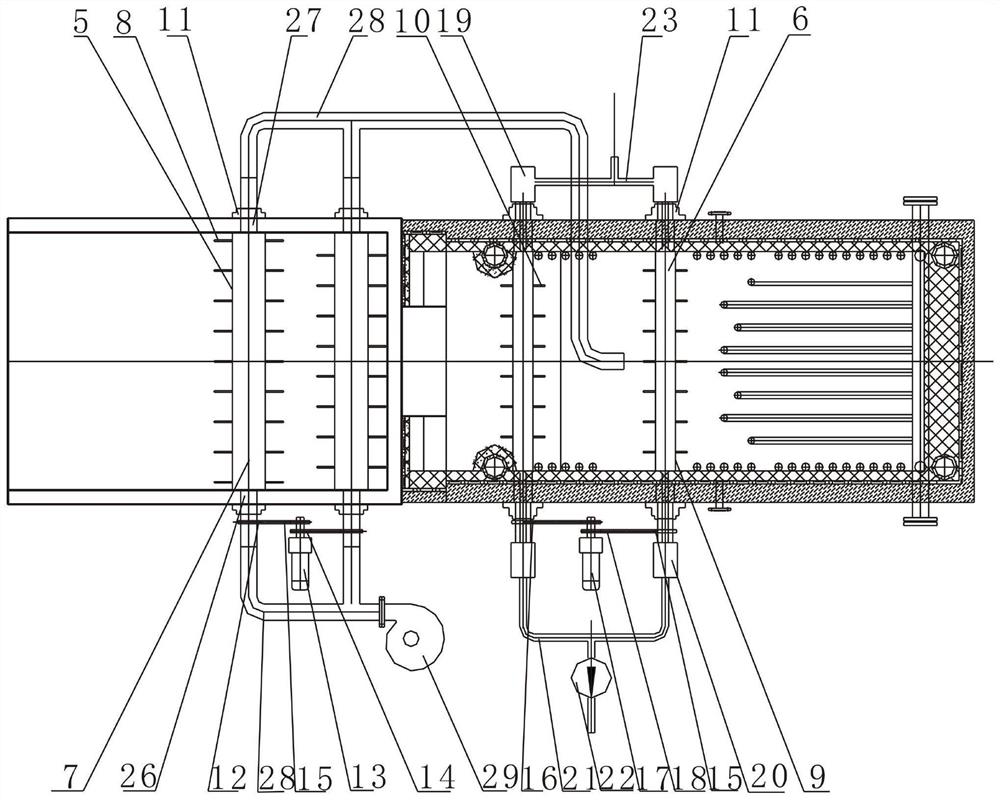

[0075] See attached figure 1 , 2 , 4, 5, the embodiment of the present invention discloses a direct-fired biomass boiler with straw baling and material removal device, including: a bale breaking roller assembly 1 and a material removal roller assembly 2 .

[0076] The bale breaking roller assembly 1 is located in the straw bale breaking chamber 3 of the boiler, the material shifting roller assembly 2 is located in the furnace 4 of the boiler, and the straw bale breaking chamber 3 is located at the front end of the straw feeding port on the furnace 4 .

[0077] The breaking roller assembly 1 includes two breaking roller spindle tubes 5 that rotate in the opposite direction or in the same direction. The outer wall of the breaking roller main tube 5 is evenly provided with a number of breaking thorns 8, and the two ends of the breaking roller main tube 5 are The end is rotatably connected with the inner wall of the straw breaking chamber 3 through the rotating bearing seat 11 . ...

Embodiment 2

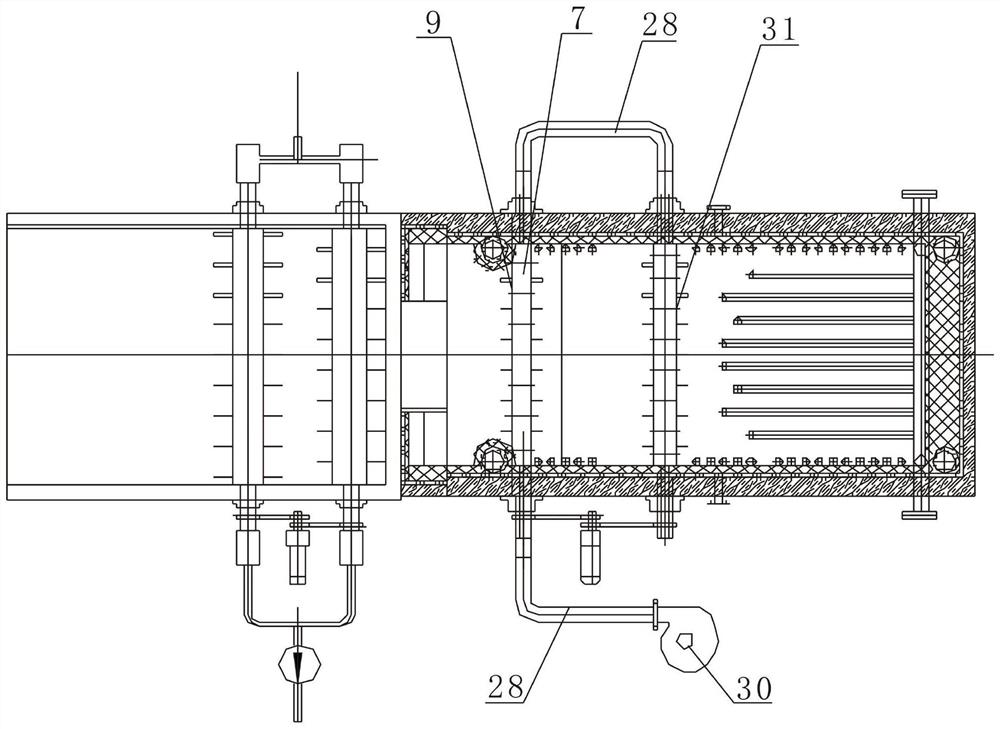

[0086] See attached figure 1 , 3 , 4, 5, the embodiment of the present invention discloses a direct-fired biomass boiler with straw baling and material removal device, including: a bale breaking roller assembly 1 and a material removal roller assembly 2 .

[0087] The bale breaking roller assembly 1 is located in the straw bale breaking chamber 3 of the boiler, the material shifting roller assembly 2 is located in the furnace 4 of the boiler, and the straw bale breaking chamber 3 is located at the front end of the straw feeding port on the furnace 4 .

[0088] The breaking roller assembly 1 includes two breaking roller spindle tubes 5 that rotate in the opposite direction or in the same direction. The outer wall of the breaking roller main tube 5 is evenly provided with a number of breaking thorns 8, and the two ends of the breaking roller main tube 5 are The end is rotatably connected with the inner wall of the straw breaking chamber 3 through the rotating bearing seat 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com