Environment-friendly, efficient and energy-saving biomass clean combustion stove for cooking, heating and kang heating

An energy-saving, biomass technology, applied in the field of boilers, can solve the problems of insufficiency and no heating kang function, and achieve the effects of increasing the use function, improving the combustion efficiency, and reducing the exhaust gas temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

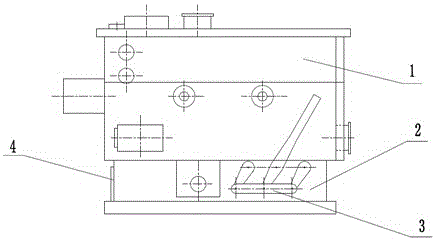

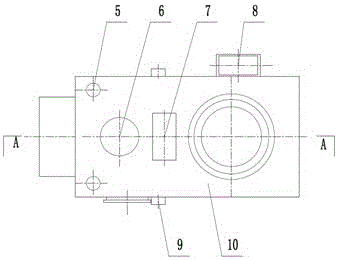

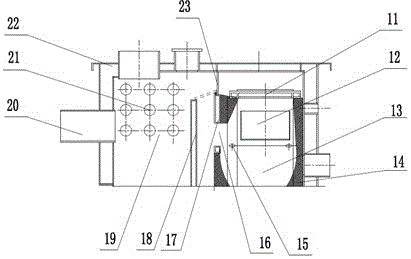

[0022] see Figure 1 to Figure 3 As shown, the environment-friendly, high-efficiency and energy-saving type cooking, heating, and hot kang of the present invention use biomass clean combustion stoves. The cavity between the shell of the stove body 1 and the inner plate forms a water jacket 22, and the gasification combustion chamber 12, The combustion space formed by the deferred combustion chamber 13 is placed in front of the stove body 1, and the front, left, and right walls of the combustion space are formed by setting refractory linings 14 inside the front, left, and right water jackets 22 of the stove body 1. The rear wall of the combustion space is formed by setting refractory lining 14 on the two front water-cooled walls 17, and the bottom of the combustion space is a movable grate device 3; the lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com