Straw bundle burning direct-fired biomass boiler with in-boiler drying function

A biomass boiler and drying technology in the furnace, which is applied in the field of straw baling and burning, can solve the problems of low thermal efficiency, slow combustion speed, slow temperature rise, etc., and achieve the effects of ensuring work reliability, reasonable structure design, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

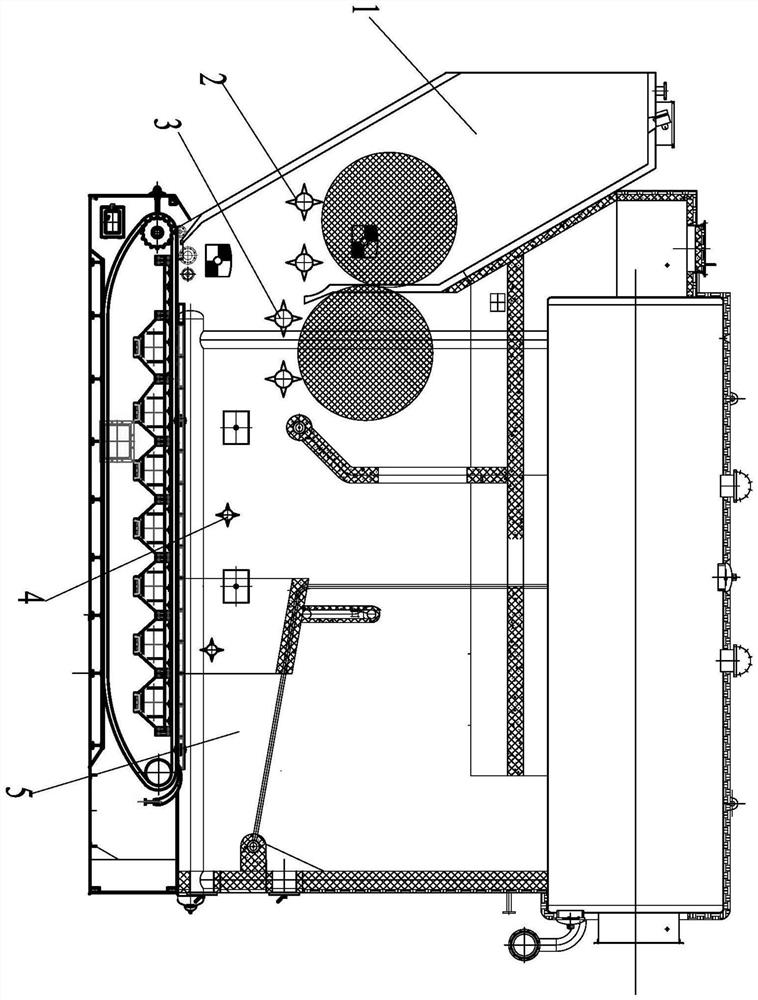

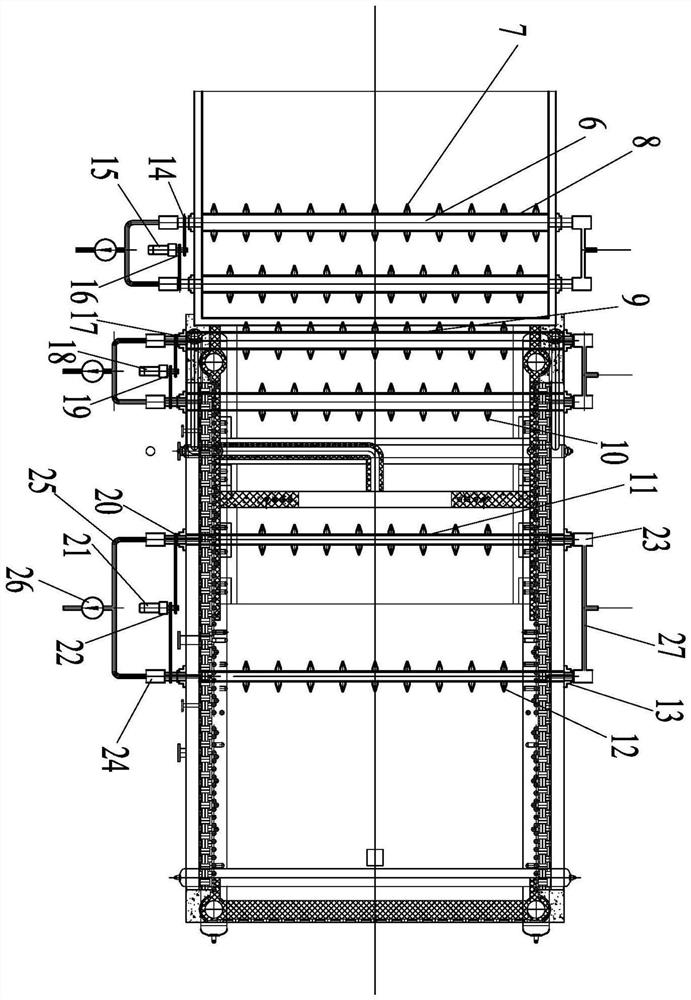

[0035] like Figure 1-3 As shown, this embodiment provides a direct-fired biomass boiler with in-furnace drying for straw bale burning, including a drying roller assembly 2, a bale breaking roller assembly 3 and a feeding roller assembly 4;

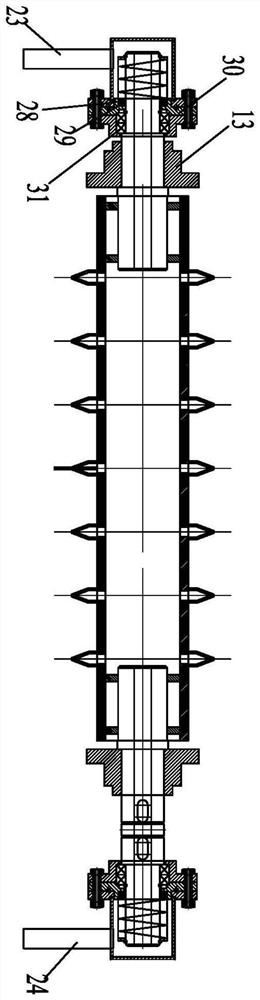

[0036]The drying roller assembly 2 is located in the drying chamber 1 inside the feed port of the boiler, and the drying roller assembly 2 includes one or two drying roller main shaft pipes 8; each drying roller main shaft pipe 8 is provided with The water cooling channel 6, the outer wall of the drying roller main shaft pipe 8 is evenly distributed with a number of drying thorns 7, the drying thorns 7 are hollow drying thorns communicated with the water cooling channel 6; the cooling water passes through the water cooling of the drying roller main shaft pipe 8 After passage 6, enter the drying thorn 7;

[0037] The bag breaking roller assembly 3 is located in the furnace 5, and the bag breaking roller assembly 3 includes one or two bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com