Bale breaking device of straw bale burning direct-fired biomass boiler

A biomass boiler and straw bale technology, which is applied in the field of agricultural machinery, can solve the problems of slow heating, slow combustion and low thermal efficiency of the boiler, and achieve the effect of prolonging the service life and ensuring the working ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] The following is based on Figure 1-9 A bale-breaking device for direct-fired biomass boilers fired with straw bales according to an embodiment of the present invention is described in detail.

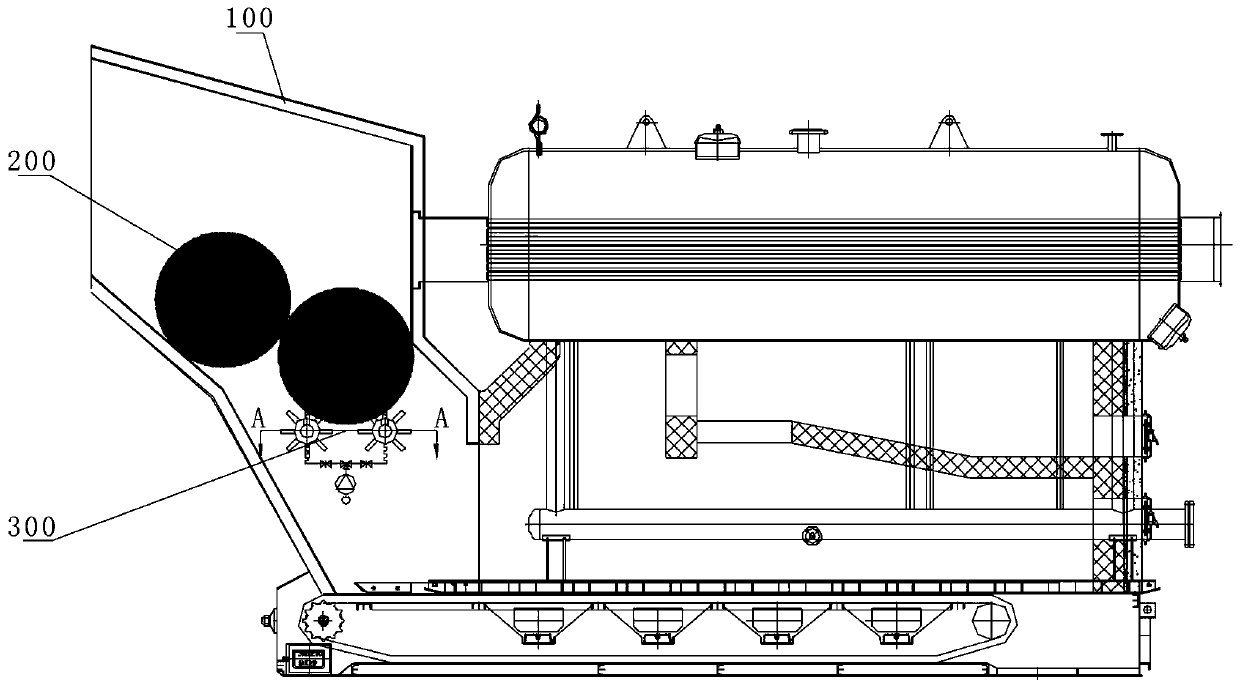

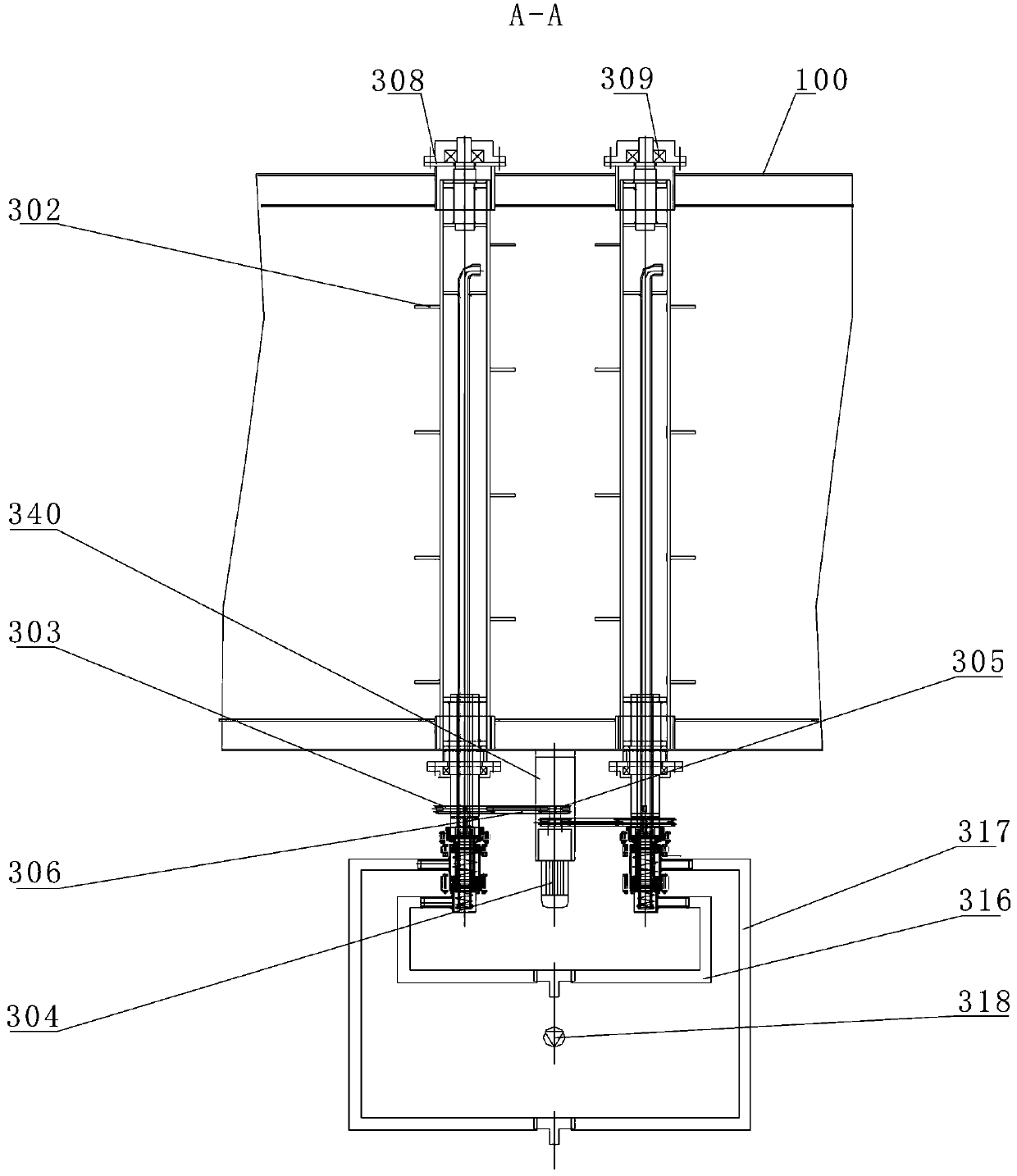

[0052] See attached figure 1 , the embodiment of the present invention discloses a bag-breaking device for a direct-fired biomass boiler fired with straw bundles, which is installed in a straw bag-breaking room 100. ; The bag-breaking device 300 includes: a bag-breaking roller assembly and a water-cooling circulation system.

[0053] specific,

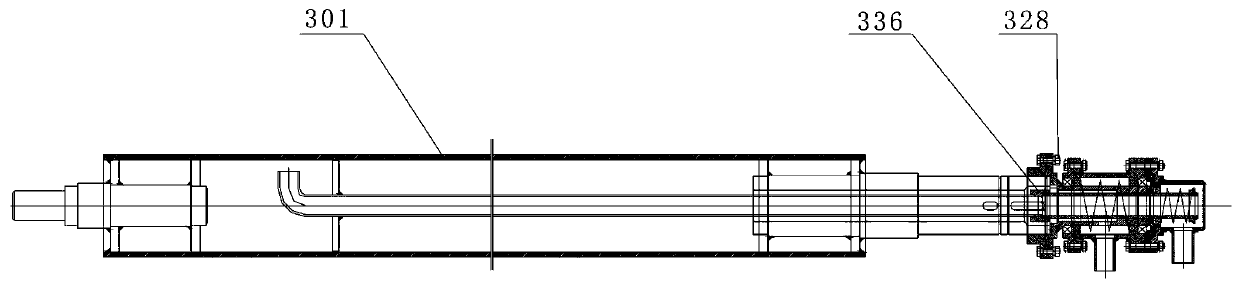

[0054] See attached figure 2 , attached image 3 , the bale breaking roller assembly includes two bale breaking roller main shaft tubes 301 arranged side by side in the straw bale breaking room 100; And the two main shaft tubes 301 of the breaking rolls rotate in opposite directions; the ring outer wall of each main shaft tube 301 of the breaking rolls is evenly provided with some breaking thorns 302; There is a bale-breaking roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com