Technology combined application method of brown coal gasification furnace and combustion heat gas hot-water boiler

A technology of hot water boiler and application method, which is applied in the direction of climate change adaptation, chemical industry, petroleum industry, etc., can solve problems such as high energy consumption, low energy efficiency, high pollution, etc., achieve high gasification intensity, solve coal direct combustion, The effect of stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

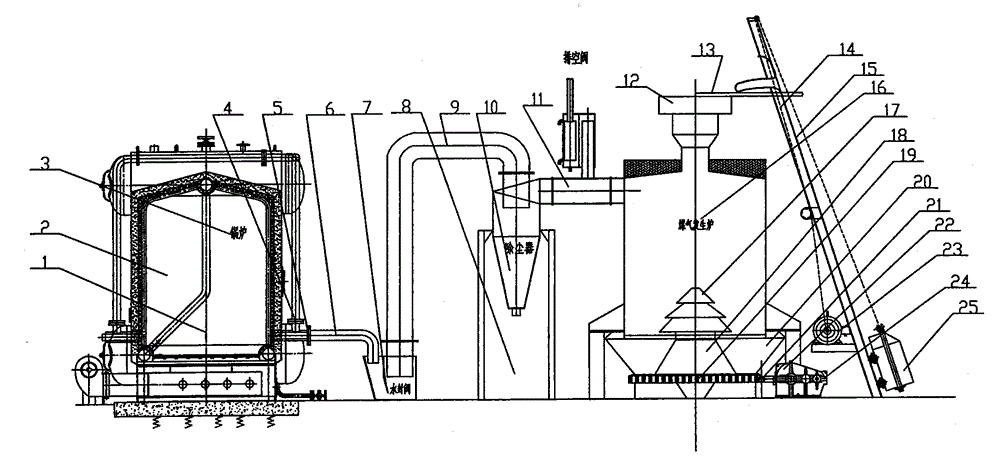

[0027] Schematic in process combination flow picture In the process, the fuel coal is fed through the single bucket (25) through the wire rope (14) and hoist (23) along the coal loading support (15) to realize automatic coal feeding, and the top of the water-sealed coal feeding box (12) is automatically opened by mechanical action. Cover (13), fuel falls in the hearth of coal gasification furnace (16), and in the process that single bucket (25) returns, adds coal box top cover (13) and relies on self gravity to close automatically.

[0028] In the automatic slag removal and ash unloading combined system, the motor (24) drives the reducer (22) to decelerate at a certain ratio, and then drives the worm (21) to rotate through the output shaft, and the worm (21) and the outer gear (19) It is a meshing relationship, so that the worm rod (21) drives the slag pan outer gear (19) to rotate, the ash basin (20) is fixed on the slag pan (19), and the grate base (18) is fixed by welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com