Line edge detection tool for detecting symmetry degree of bayonet of bearing cover and detection method of line edge detection tool

A technology for bearing caps and symmetry, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of large volume of three-coordinate detection machines, low detection efficiency, and large inspection workload, so as to achieve convenient positioning and reduce The effect of small cost expenditure and inspection load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will be described in detail in conjunction with specific embodiments.

[0036] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

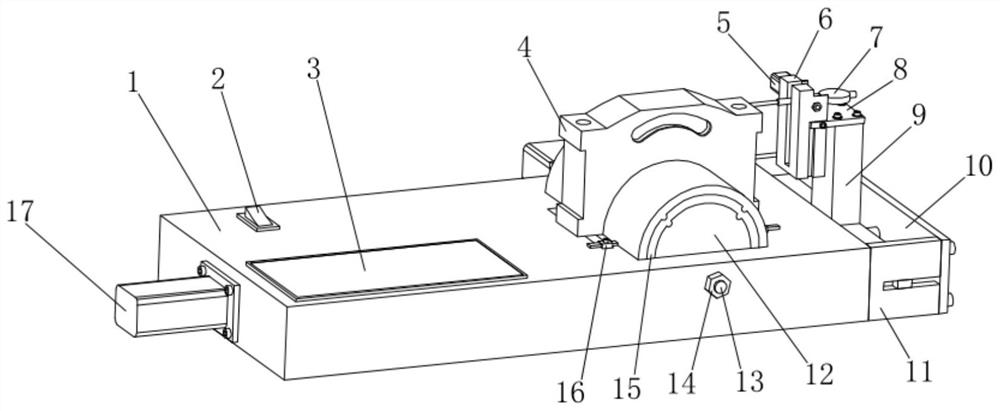

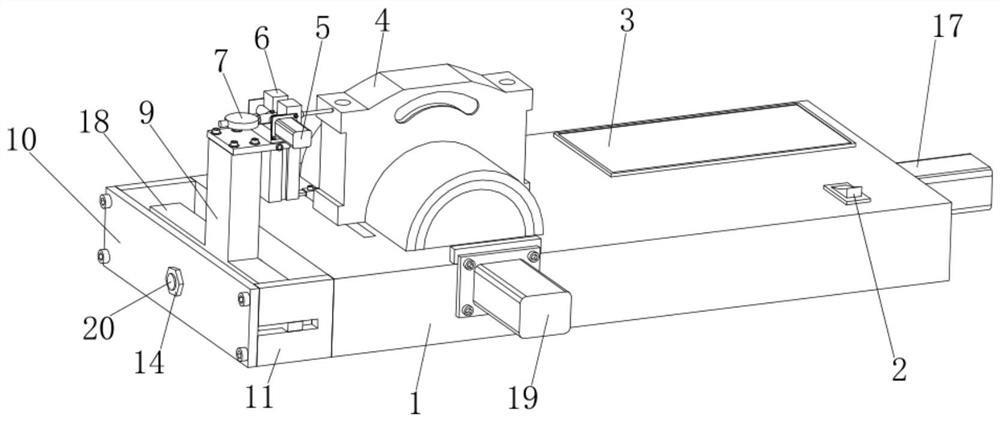

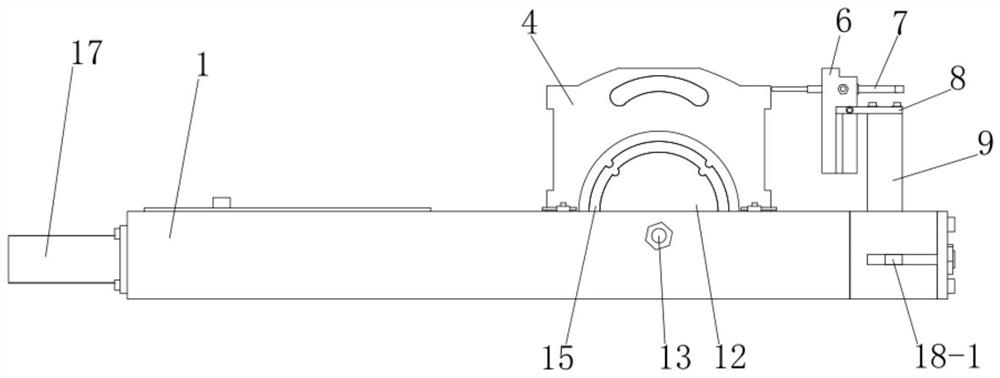

[0037] Such as Figure 1-9As shown, a line edge inspection tool for detecting the symmetry of the bearing cover bayonet includes a fixed plate 1 and a detection mechanism. The bottom of the fixed plate 1 is provided with a rectangular cavity. The through hole of the shaft, two through holes are provided with a first screw mandrel 20, the left end of the fixed plate 1 is provided with the first motor 17, the rotating shaft of the first motor 17 is connected with the left end of the first screw mandrel 20, the fixed plate 1 The right end of the long baffle is provided with a baffle, and the baffle is composed of a long baffle 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com