Visual liquid nitrogen freeze-thaw coal crack propagation dynamic monitoring system

A crack propagation and dynamic monitoring technology, which is applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of inability to visually monitor coal deformation and damage characteristics, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

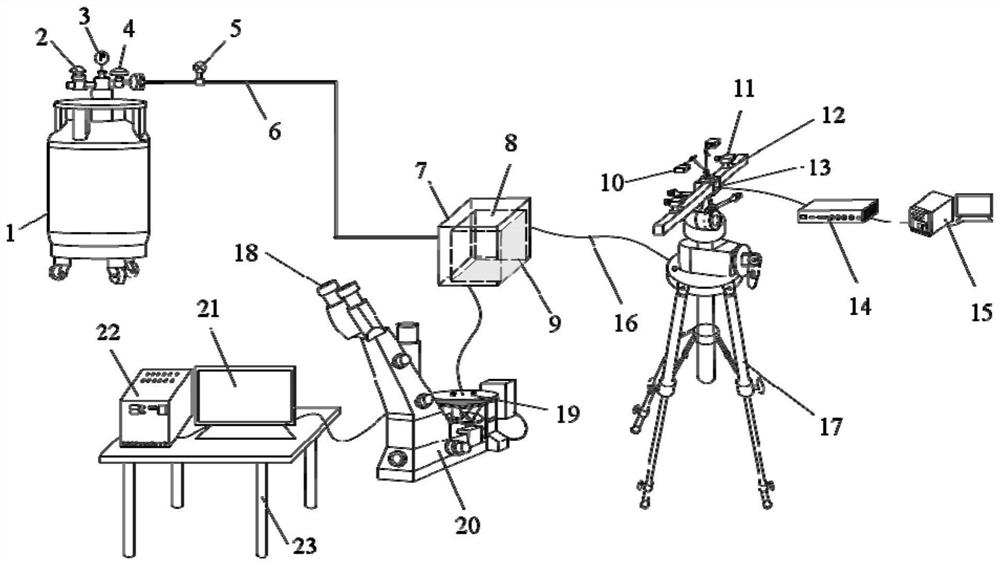

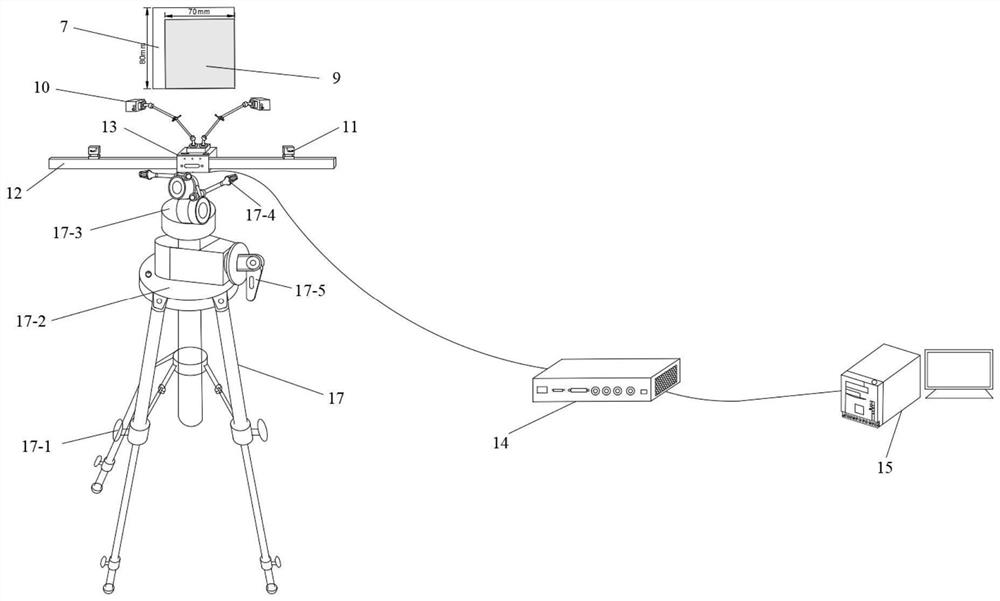

[0027] see figure 1 , 2 , 3, a visual liquid nitrogen freeze-thaw coal body crack growth dynamic monitoring system, including liquid nitrogen injection system and liquid nitrogen freeze-thaw system, also includes optical speckle monitoring system and inverted metallographic microscope monitoring system.

[0028] The optical speckle monitoring system includes a speckle light source 10, a high-speed camera 11, a speckle control box 14, and a speckle analysis system 15. There are two speckle light sources 10 and two high-speed cameras 11 respectively, and the high-speed cameras 11 are connected through data Line 16 is connected to speckle control box 14 .

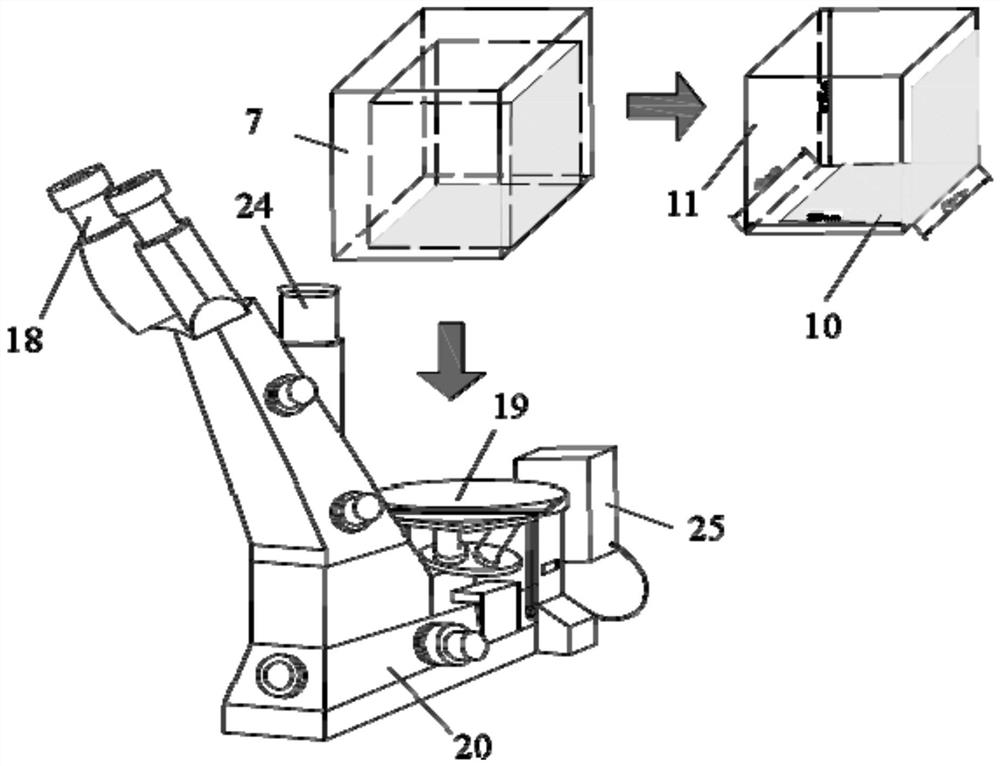

[0029] Described inverted metallographic microscope monitoring system comprises eyepiece 18, microscope table 19, inverted metallographic microscope 20, display 21, computer 22, experiment table 23, adapter mirror 24 and image collector 25, inverted metallographic microscope 20, display 21 and computer 22 are placed on the e...

Embodiment 2

[0031] see figure 1 , 2 , 3, a visual liquid nitrogen freeze-thaw coal body crack growth dynamic monitoring system, including liquid nitrogen injection system and liquid nitrogen freeze-thaw system, also includes optical speckle monitoring system and inverted metallographic microscope monitoring system.

[0032] The optical speckle monitoring system includes a speckle light source 10, a high-speed camera 11, a speckle control box 14, and a speckle analysis system 15. There are two speckle light sources 10 and two high-speed cameras 11 respectively, and the high-speed cameras 11 are connected through data Line 16 is connected to speckle control box 14 .

[0033] Described inverted metallographic microscope monitoring system comprises eyepiece 18, microscope table 19, inverted metallographic microscope 20, display 21, computer 22, experiment table 23, adapter mirror 24 and image collector 25, inverted metallographic microscope 20, display 21 and computer 22 are placed on the e...

Embodiment 3

[0037] see figure 1 , 2 , 3, a visual liquid nitrogen freeze-thaw coal body crack growth dynamic monitoring system, including liquid nitrogen injection system and liquid nitrogen freeze-thaw system, also includes optical speckle monitoring system and inverted metallographic microscope monitoring system.

[0038] The optical speckle monitoring system includes a speckle light source 10, a high-speed camera 11, a speckle control box 14, and a speckle analysis system 15. There are two speckle light sources 10 and two high-speed cameras 11 respectively, and the high-speed cameras 11 are connected through data Line 16 is connected to speckle control box 14 .

[0039] Described inverted metallographic microscope monitoring system comprises eyepiece 18, microscope table 19, inverted metallographic microscope 20, display 21, computer 22, experiment table 23, adapter mirror 24 and image collector 25, inverted metallographic microscope 20, display 21 and computer 22 are placed on the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistant | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com