Heat exchanger with observation window and for low temperature of 80K

An 80K, heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat storage equipment, etc., can solve problems such as sealing failure, achieve the effect of improving stiffness, meeting high pressure requirements, and realizing visual observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

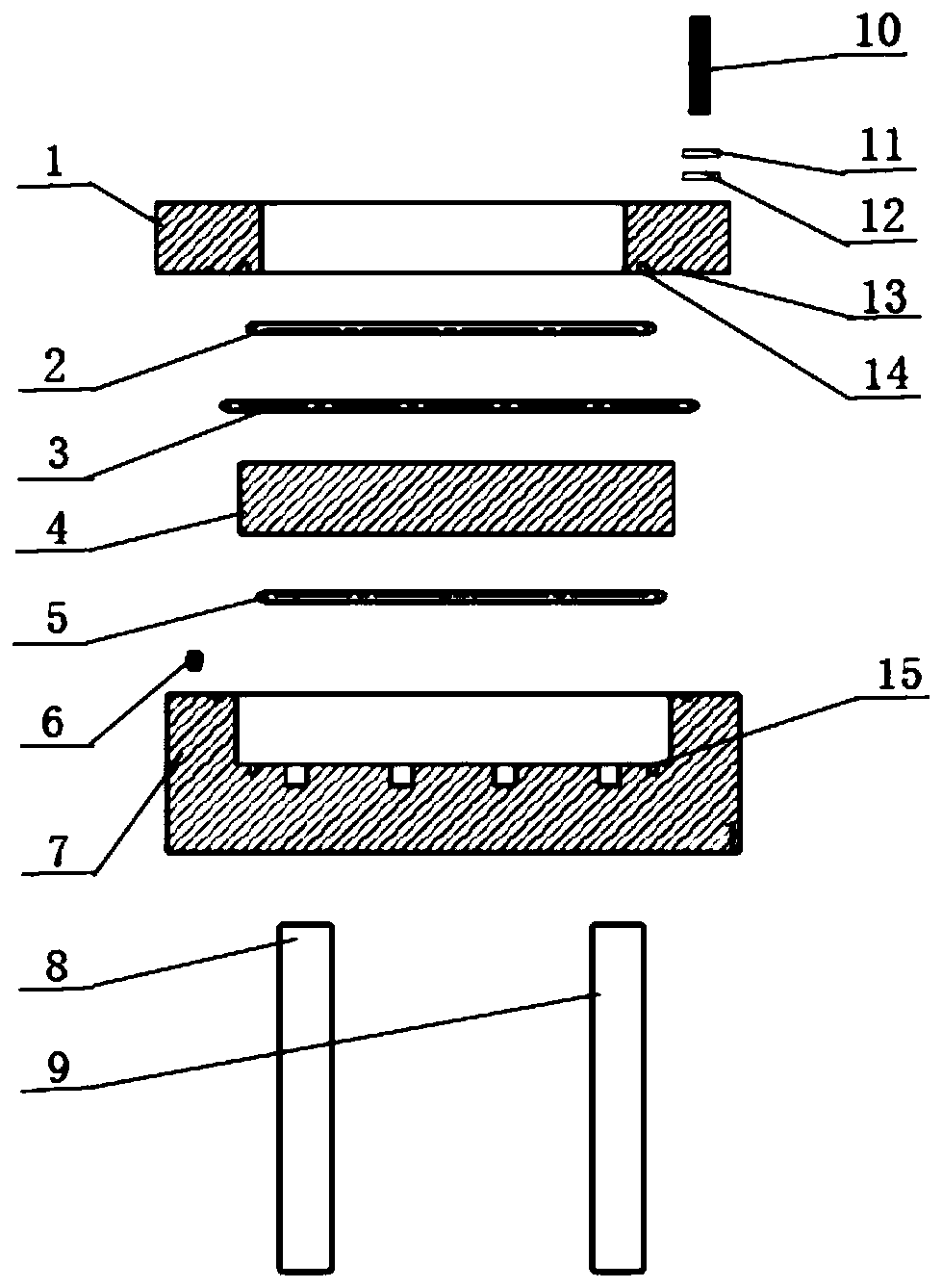

[0022] In conjunction with the accompanying drawings, the structural principle of the present invention will be further described in detail below.

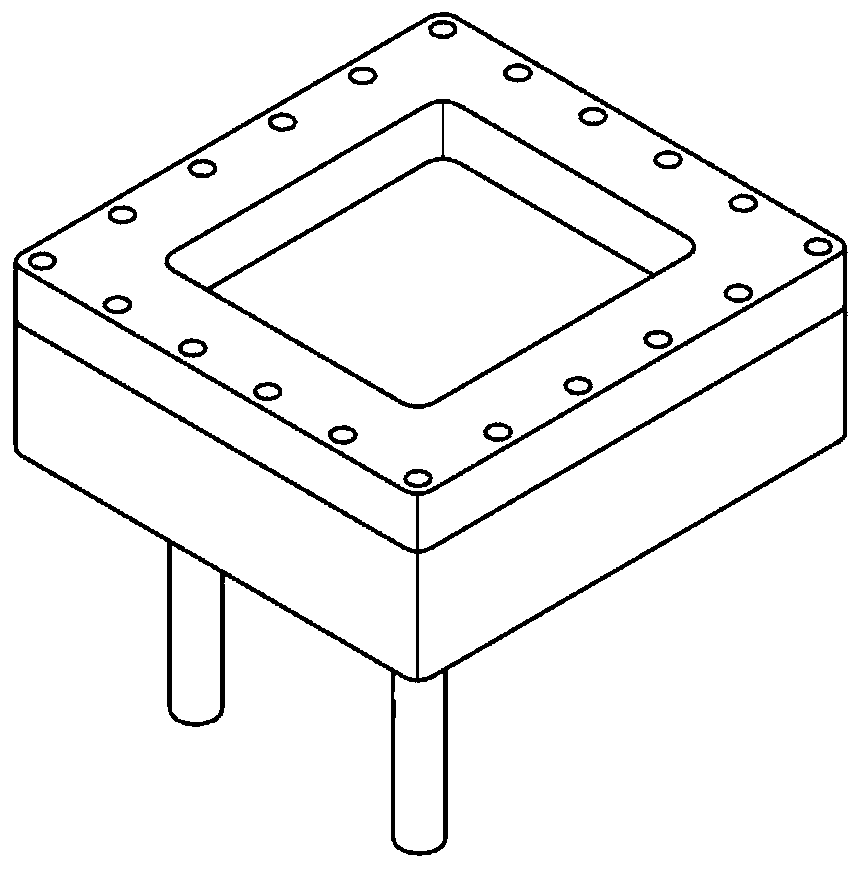

[0023] The heat exchanger with observation windows that can be used at 80K low temperature according to the present invention, refer to the attached figure 1 , 2 , the present invention is mainly different from the structure of conventional converters and includes:

[0024] Indium wire 2 for sealing the cover plate 1 and the observation window 4, indium wire 3 for sealing the cover plate 1 and the phase change chamber 7, observation window 4, and indium for sealing the observation window 4 and the phase change chamber 7 Wire 5, steel wire screw sleeve 6.

[0025] Refer to attached figure 2 , shows an example of a heat exchanger with an observation window for 80K low temperature designed according to the design concept of the present invention. As shown in the figure, the overall size of the heat exchanger is 70*66*26mm; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com