A foam stability testing device and working method under pressure fluctuation

A technology of foam stability and testing equipment, which is applied in measuring equipment, fluid dynamics testing, testing of machine/structural components, etc. It can solve the problem of not considering the influence of pressure factors, the inability to simulate the pressure change environment, and affecting the reliability of test data and other issues to achieve the effect of strong pressure resistance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

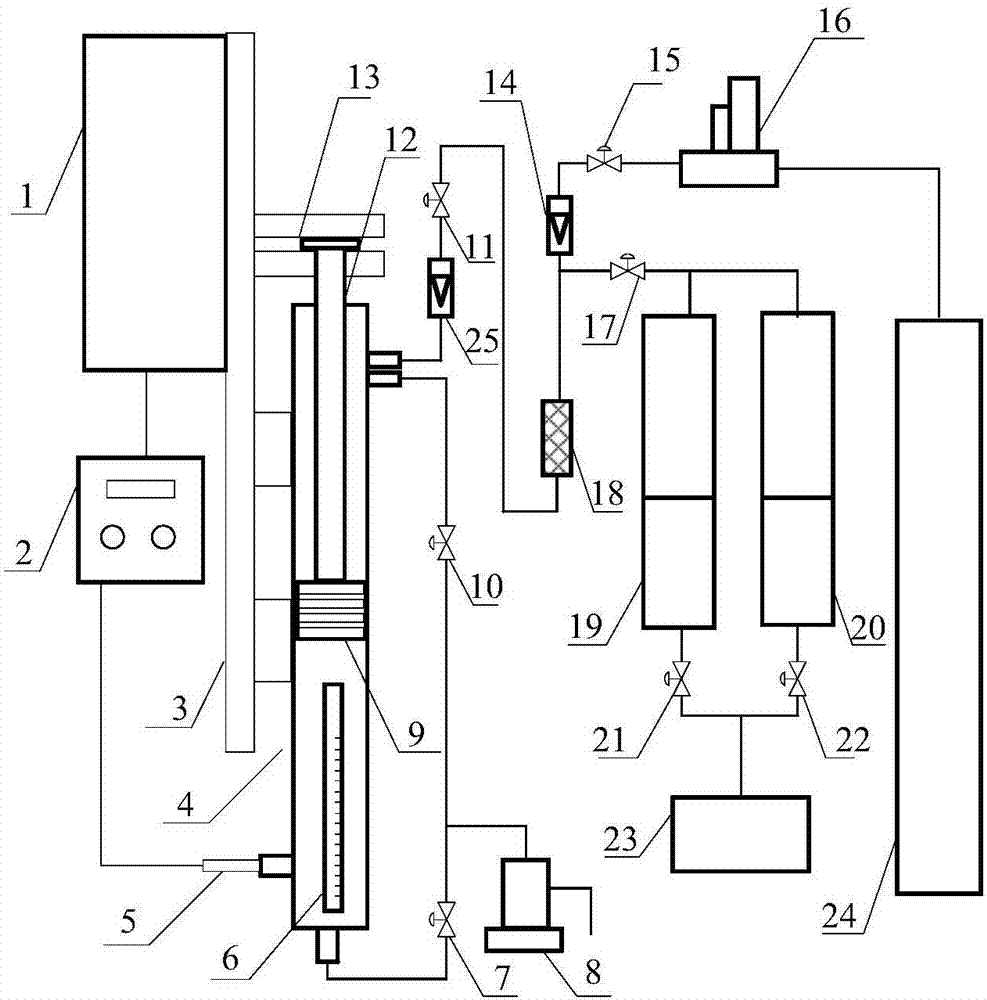

[0041] A foam stability testing device under pressure fluctuations, comprising a foam generating part, a foam testing part, a pressure regulating part and a cleaning part; the foam generating part, the pressure regulating part and the cleaning part are respectively connected in parallel with the foam testing part, and realized by valve control : Separate series connection of foam generation part and foam test part; separate series connection of pressure regulation part and foam test part; separate series connection of cleaning part and foam test part.

[0042] The foam generating part includes a gas cylinder 24, a gas flow controller 16, a third valve 15, a first one-way valve 14, a foam generator 18, a seventh valve 11 and a second one-way valve connected in sequence along the gas flow direction 25. A foaming liquid intermediate container 19 is arranged in parallel with the foam generator 18, and the bottom of the foaming liquid intermediate container 19 is connected with an a...

Embodiment 2

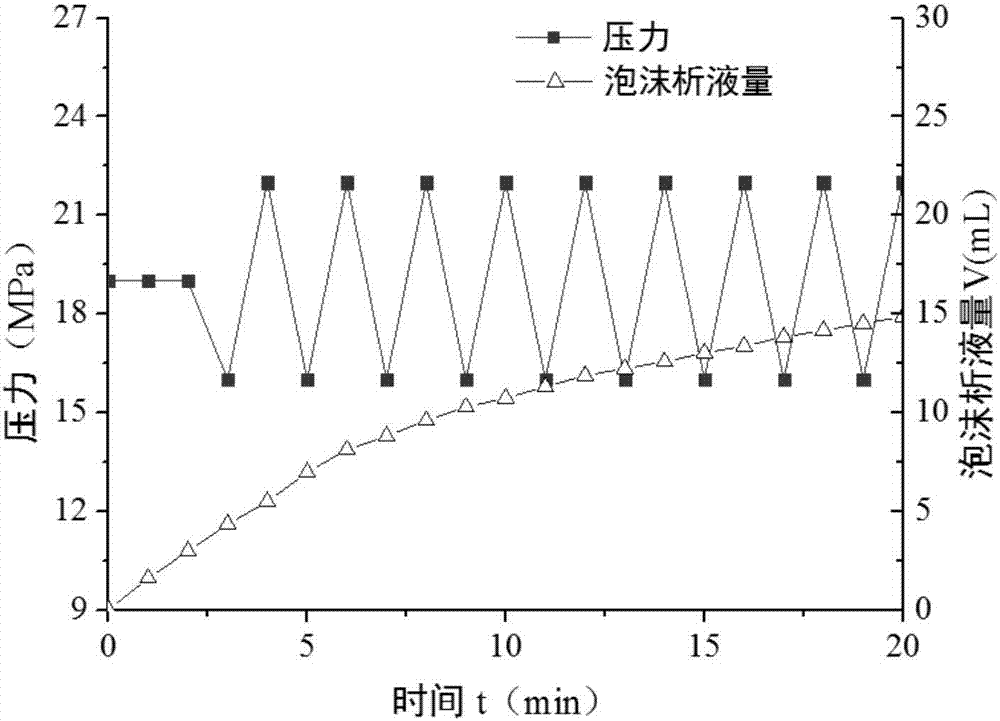

[0049] A kind of working method that utilizes testing device test foam stability under pressure fluctuation as described in embodiment 1, comprises steps as follows:

[0050] (1) Start the test device:

[0051] Connect the various components of the test device, start the electric control box 2, start the advection pump 23, and start the gas flow controller 16;

[0052] (2) Exhaust:

[0053] Open the valve first valve 7, the second valve 10; close the seventh valve 11; adjust the electric control box 2 to control the high-torque stepping motor 1 after the piston 9 is raised to the top of the test cylinder 4, open the seventh valve 11, The fourth valve 17, the sixth valve 22; close the first valve 7, the fifth valve 21; adjust the advection pump 23, drive the distilled water in the distilled water intermediate container 20 into the test cylinder 4, until the distilled water flows out from the back pressure valve 8, Stop the advection pump 23;

[0054] (3) Generate foam:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com