Chromatographic analysis device and method

A chromatographic analysis and chromatographic column technology, applied in the direction of measuring devices, analytical materials, material separation, etc., can solve the problems of carrier gas path dead volume, high processing difficulty, and gas path fluctuations, so as to achieve stable air flow and avoid broadening of chromatographic peaks , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The chromatographic analysis device of the embodiment of the present invention, the chromatographic analysis device comprises:

[0031] The enrichment tube, the first chromatographic column and the first detector, these devices are all prior art in this field;

[0032] a body, the body has a first channel, a second channel, a third channel, a fourth channel and a fifth channel distributed in a clockwise direction, and the second channel and the fifth channel respectively communicate with the first channel , the third channel communicates with the fourth channel, and communicates with the fifth channel as required; the first channel and the fourth channel are collinear (central axes are collinear), and the second channel and the The fifth channel is collinear (central axes are collinear) and is perpendicular to the first channel, and the third channel is perpendicular to the fourth channel;

[0033] A pressure adjustment module, such as EPC, the pressure adjustment modu...

Embodiment 2

[0045] The chromatographic analysis device of embodiment 1 of the present invention is different from embodiment 1 in that:

[0046] No communication tube is provided, the first channel and the fourth channel are connected, and a rotating member is provided at the outlet of the third channel, respectively used to close the outlet and isolate the fifth channel and the third channel.

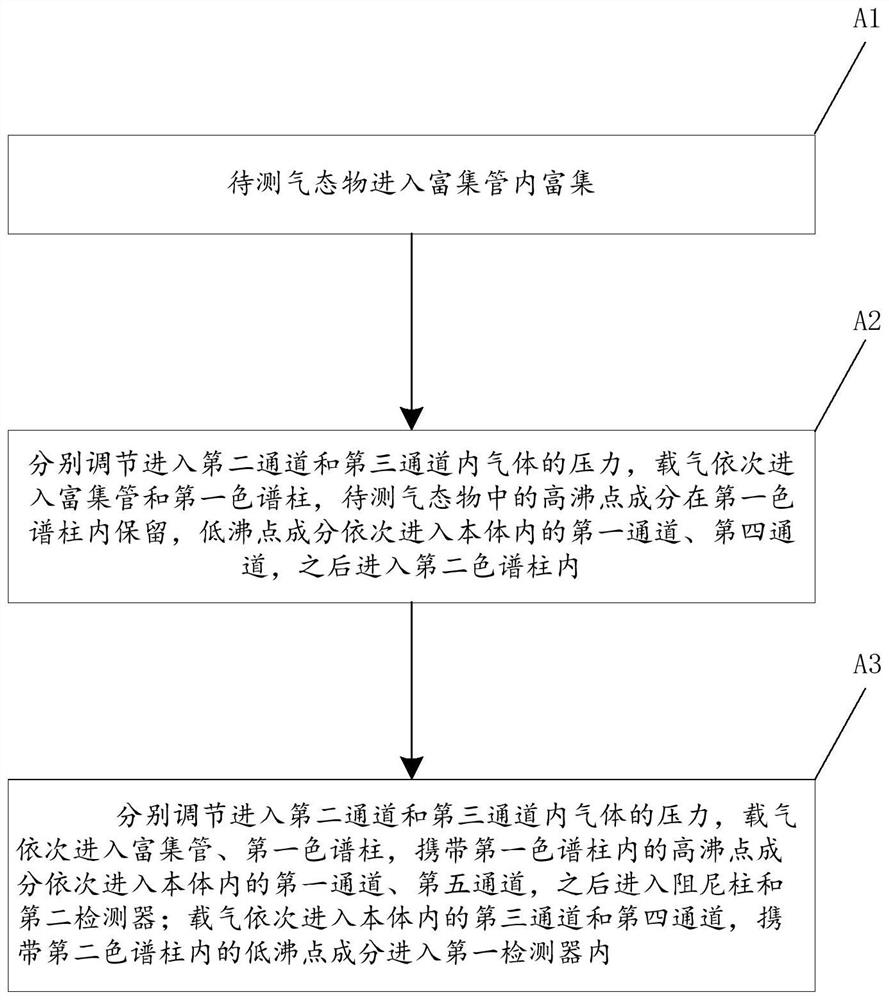

[0047] The chromatographic analysis method of the embodiment of the present invention, that is, the working method of the chromatographic analysis device according to the present embodiment, such as figure 1 Shown, described chromatographic analysis method comprises the following steps:

[0048] (A1) The gaseous substances to be measured are enriched in the enrichment tube sequentially;

[0049] (A2) Adjust the pressure of the gas entering the second channel and the third channel respectively, specifically: the pressure of the gas in the second channel is not greater than the pressure of the gas ...

Embodiment 3

[0055] The chromatographic analysis device of embodiment 1 of the present invention is different from embodiment 1 in that:

[0056] A pressure adjustment module is also arranged on the upstream of the enrichment pipe, which is used to adjust the gas pressure upstream of the enrichment pipe, so that by actively adjusting the gas pressure in the first channel, the second channel and the third channel, the pressure in the first channel can be realized. Gas selectively enters the fourth and fifth channels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com