Method for diagnosing rolling bearing fault based on stochastic resonance and autoencoder

A technology of automatic encoder and rolling bearing, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc. It can solve problems such as lack of noise energy, neglect of parameter interaction, and inability to transfer noise energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

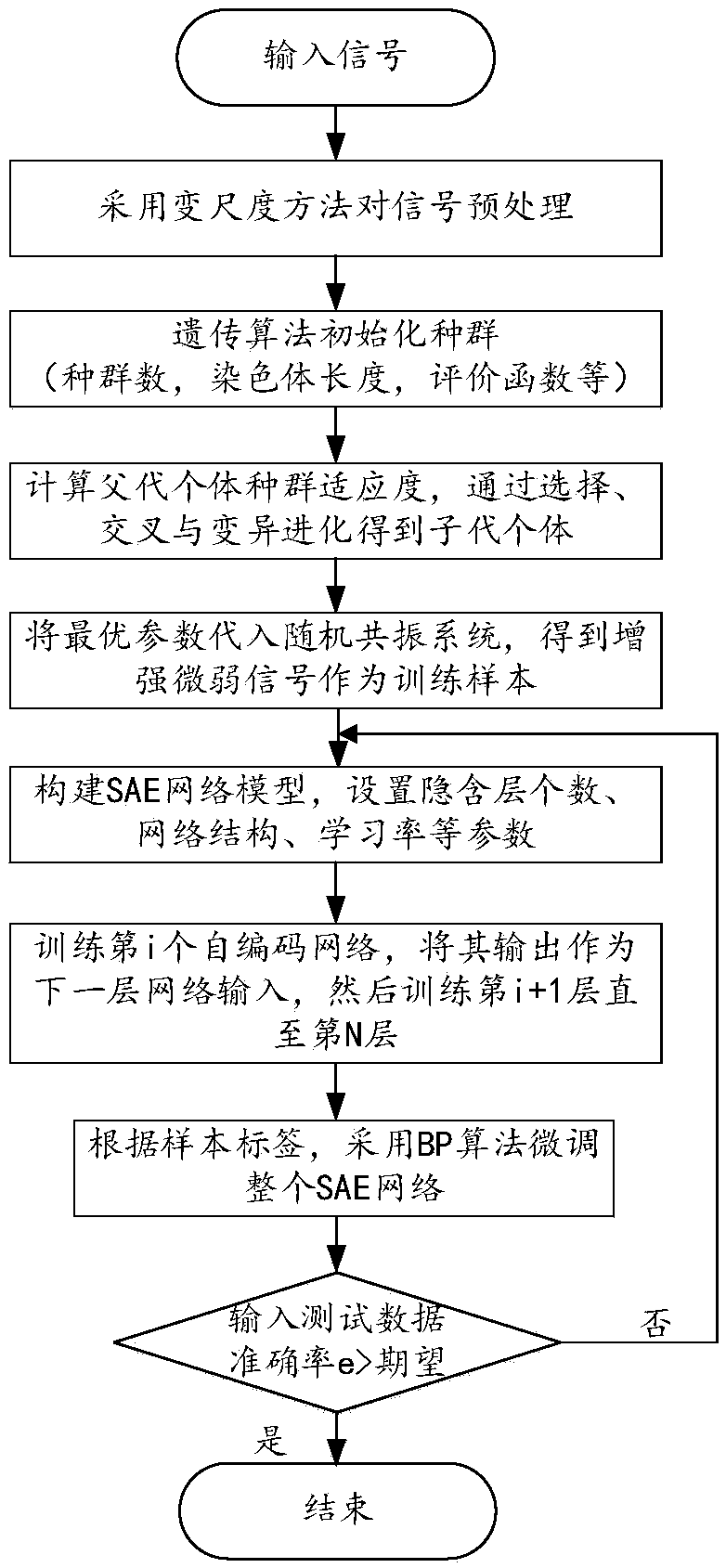

[0033] The flow chart of the rolling bearing fault diagnosis method based on stochastic resonance and automatic encoder of the present invention is shown in the appendix figure 1 .

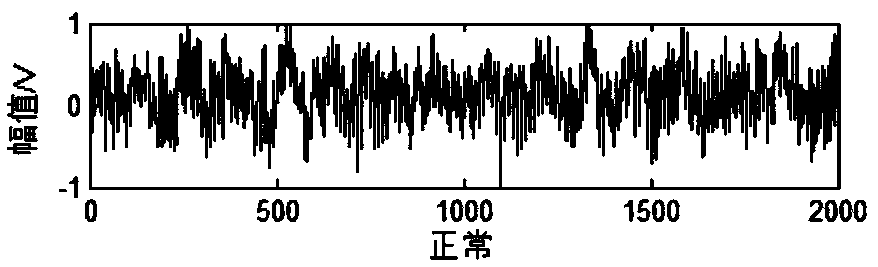

[0034] In order to verify the effect of the AGSR algorithm for extracting features, the present invention analyzes the bearing fault data of the Bearing Data Center of Case Western Reserve University in the United States, and analyzes the vibration signals of rolling bearings under various fault states. The fault diagnosis test bench is composed of a motor, a torque sensor, a power tester and an electrical control device, and the sensor is installed above the bearing seat of the driving end. The bearing model of the driving end is SKF6205. The bearing is processed by EDM technology for single point damage. A pit with a diameter of 0.178mm is set on the inner ring, outer ring and rolling body of the bearing, and the sampling frequency is 48kHz. The four bearing states used in the test are shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com