A modular tunnel excavation simulation test device and its assembly method

A tunnel excavation and simulation test technology, which is applied in the direction of assembly machines, soil material testing, material inspection products, etc., can solve the problems of low model reuse rate, difficulty in simulating stratum loss, and inability to adjust the radius, etc., to achieve good linearity, The effect of reducing impact and reducing cost of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] For better understanding of the present invention, the present invention will be further described below with reference to specific embodiments and accompanying drawings.

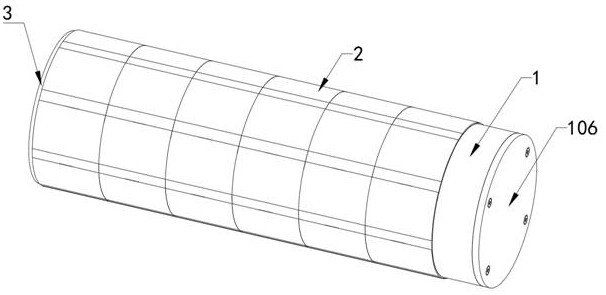

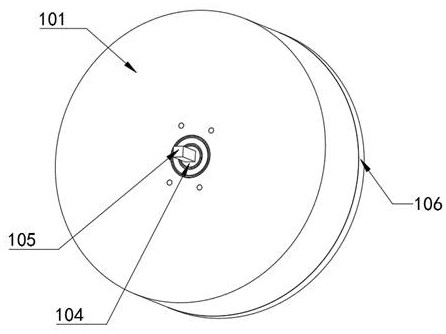

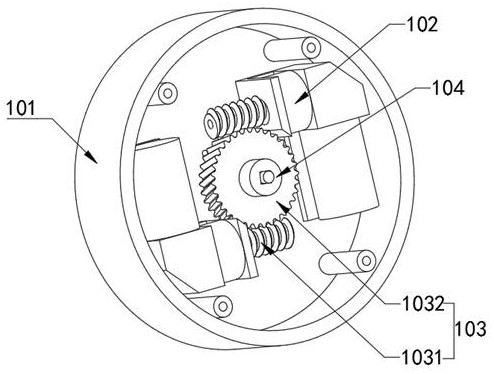

[0045] like Figure 1-Figure 11 As shown, a modular tunnel excavation simulation test device includes a driving part 1, the output end of the driving part 1 is connected with a tunnel model, the driving part 1 is used to drive the tunnel model to change its own diameter, and the tunnel model consists of at least one set of The excavation module 2 is composed, and the end of the tunnel model away from the driving part 1 is provided with a closing assembly 3 .

[0046] Specifically, in the present invention, one or more groups of excavation modules 2 are spliced into a tunnel model according to the simulation requirements, and fixed rods are used to fix the connection between the tunnel model and the driving component 1, so as to realize the integration of the tunnel excavation modules. Assembly; du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com