Method, device and equipment for calculating thermal desorption heat of resin matrix material and medium

A technology of resin matrix and calculation method, used in computer-aided design, calculation, design optimization/simulation, etc., can solve the problems of linear interpolation not reflecting nonlinear effects, large degrees of freedom in feature point selection, and large differences in calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

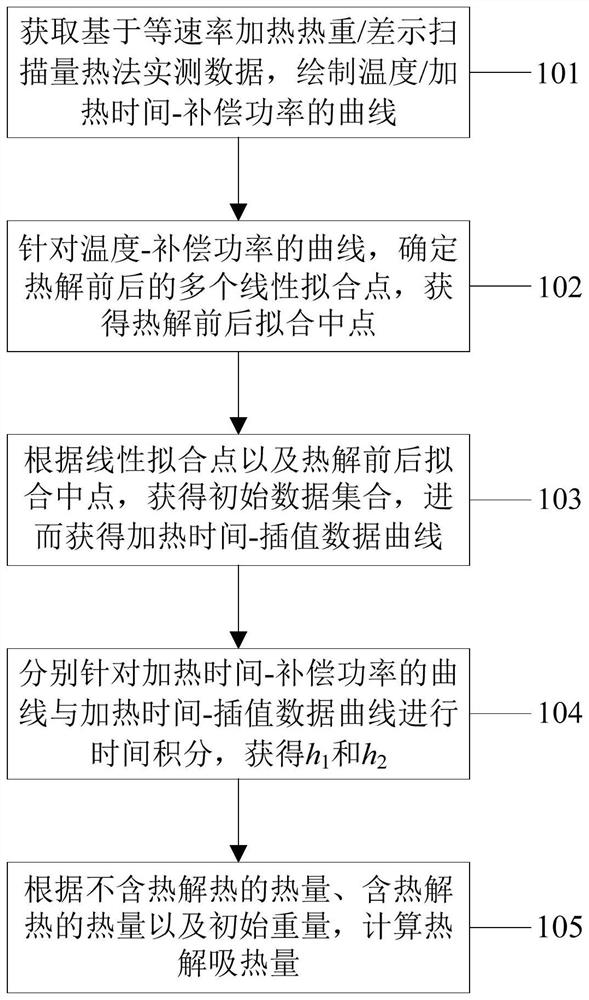

[0082] figure 1 A flow chart showing the steps of the method for calculating the heat of thermal desorption of a resin matrix material according to an embodiment of the present invention.

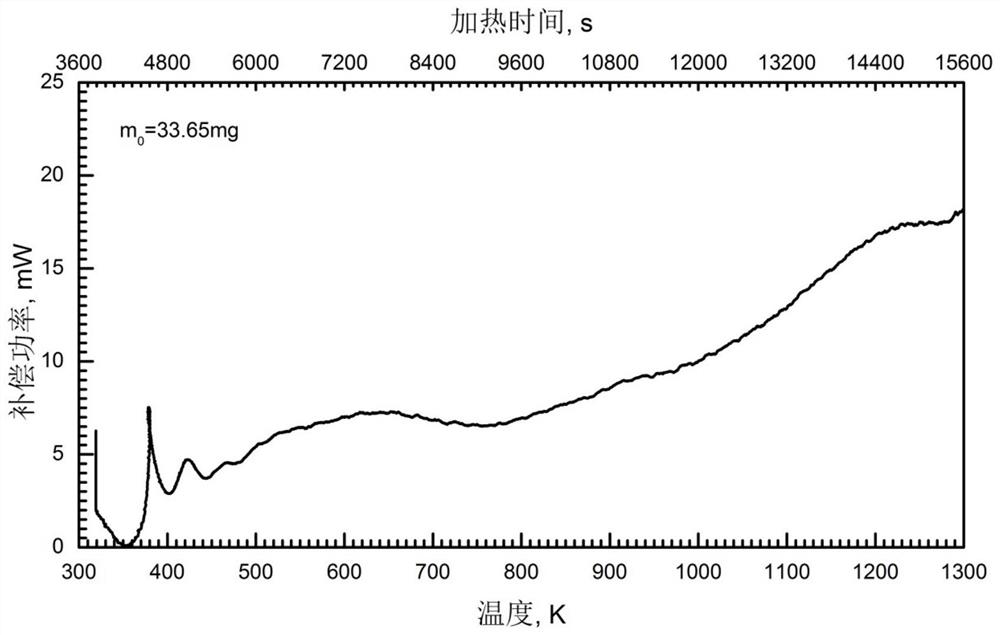

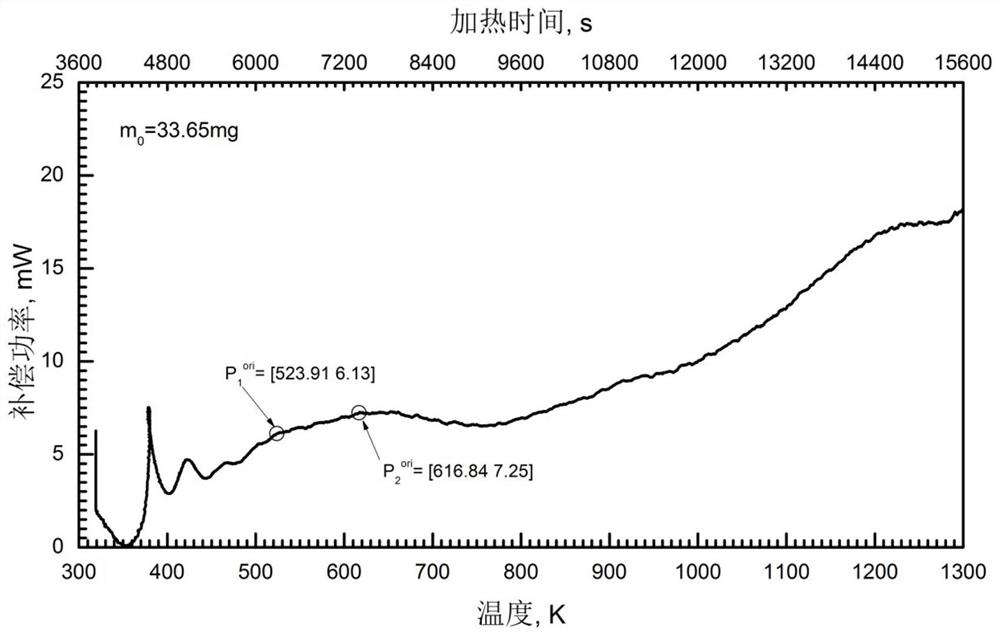

[0083] Such as figure 1 As shown, the method for calculating the heat of thermal desorption of the resin matrix material includes: step 101, obtaining measured data based on constant-rate heating thermogravimetric / differential scanning calorimetry, and drawing a curve of temperature / heating time-compensated power; step 102 , for the temperature-compensated power curve, determine a plurality of linear fitting points before and after pyrolysis, and then perform linear fitting respectively to obtain the fitting midpoint before and after pyrolysis; step 103, according to the multiple linear fitting points before and after pyrolysis point and the midpoint before and after pyrolysis, to obtain the initial data set, and then to obtain the heating time-interpolation data curve; step 104, time-inte...

Embodiment 2

[0122] Figure 15 A block diagram of a calculation device for thermal desorption heat of a resin matrix material according to an embodiment of the present invention is shown.

[0123] Such as Figure 15 As shown, the thermal desorption heat calculation device of the resin matrix material includes:

[0124] The initial module 201 is to obtain the measured data based on constant-rate heating thermogravimetry / differential scanning calorimetry, and draw a curve of temperature / heating time-compensation power;

[0125] The fitting module 202 determines a plurality of linear fitting points before and after pyrolysis for the temperature-compensated power curve, and then performs linear fitting respectively to obtain the fitting midpoint before and after pyrolysis;

[0126] The interpolation module 203 obtains an initial data set according to a plurality of linear fitting points before and after pyrolysis and a fitting midpoint before and after pyrolysis, and then obtains a heating t...

Embodiment 3

[0148] The present disclosure provides an electronic device comprising: a memory storing executable instructions; a processor running the executable instructions in the memory to implement the method for calculating thermal desorption heat of a resin matrix material.

[0149] An electronic device according to an embodiment of the present disclosure includes a memory and a processor.

[0150] The memory is used to store non-transitory computer readable instructions. Specifically, the memory may include one or more computer program products, which may include various forms of computer-readable storage media, such as volatile memory and / or non-volatile memory. The volatile memory may include, for example, random access memory (RAM) and / or cache memory (cache). The non-volatile memory may include, for example, a read-only memory (ROM), a hard disk, a flash memory, and the like.

[0151] The processor may be a central processing unit (CPU) or other form of processing unit having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com