Energy-saving motor with heat dissipation function

A heat dissipation mechanism and function technology, applied in the field of energy-saving motors with heat dissipation function, can solve the problems of power reduction of the motor body, affect the normal use of the motor, and weaken the power of the motor body, so as to avoid power reduction and ensure normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

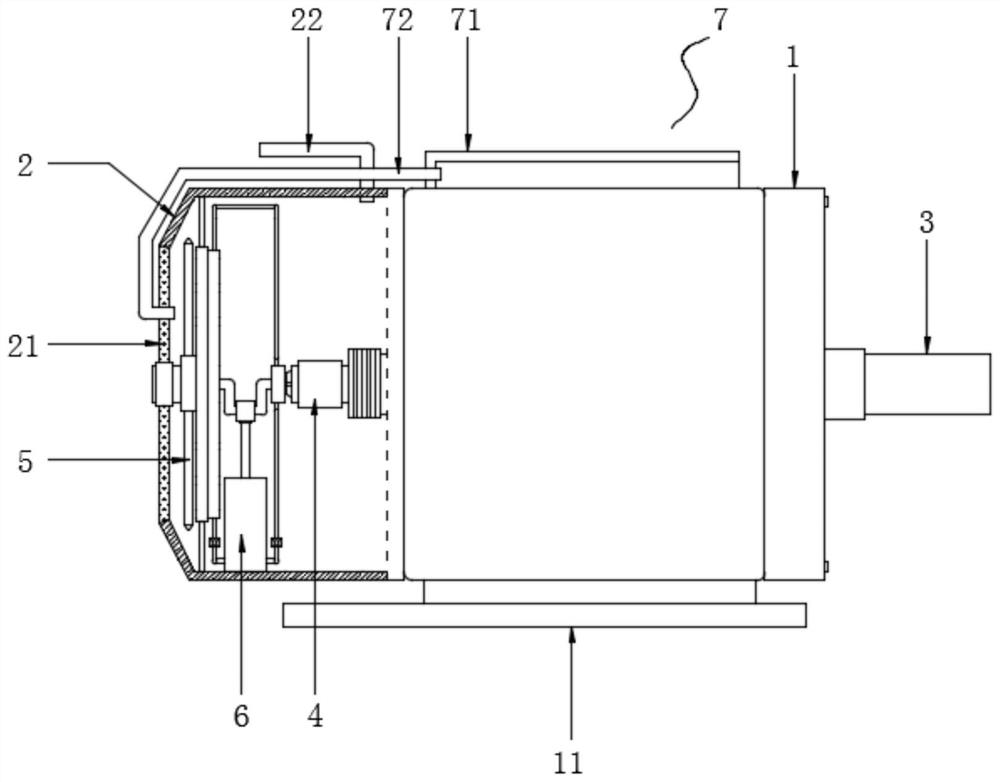

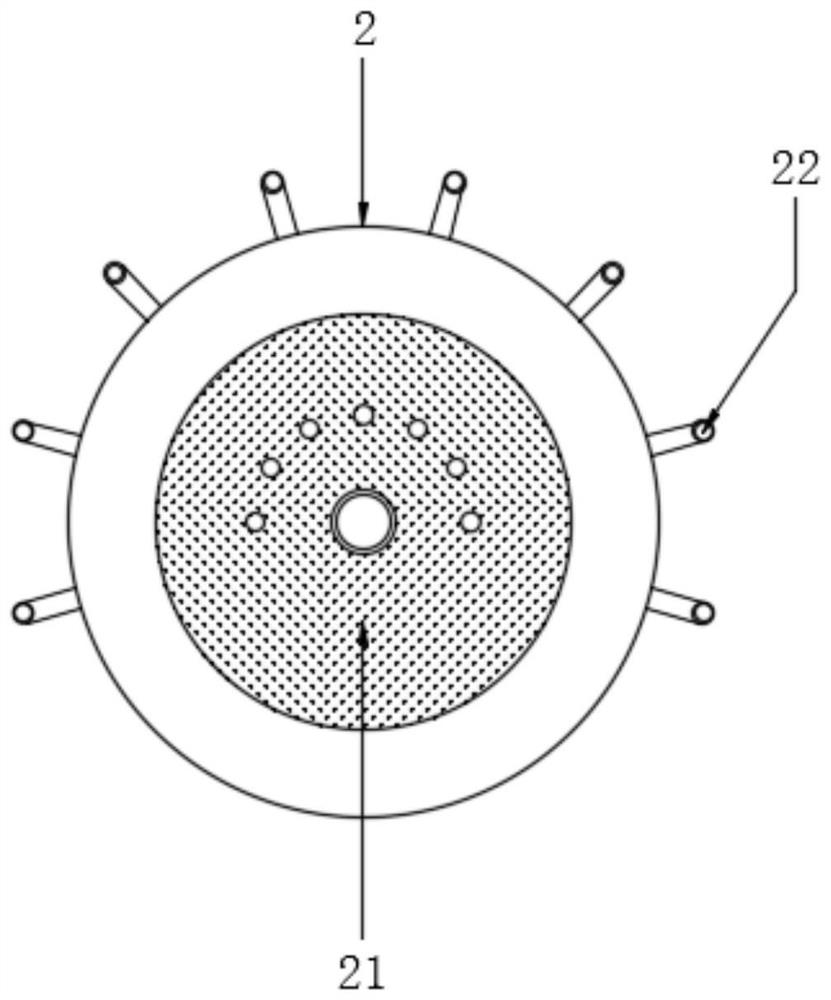

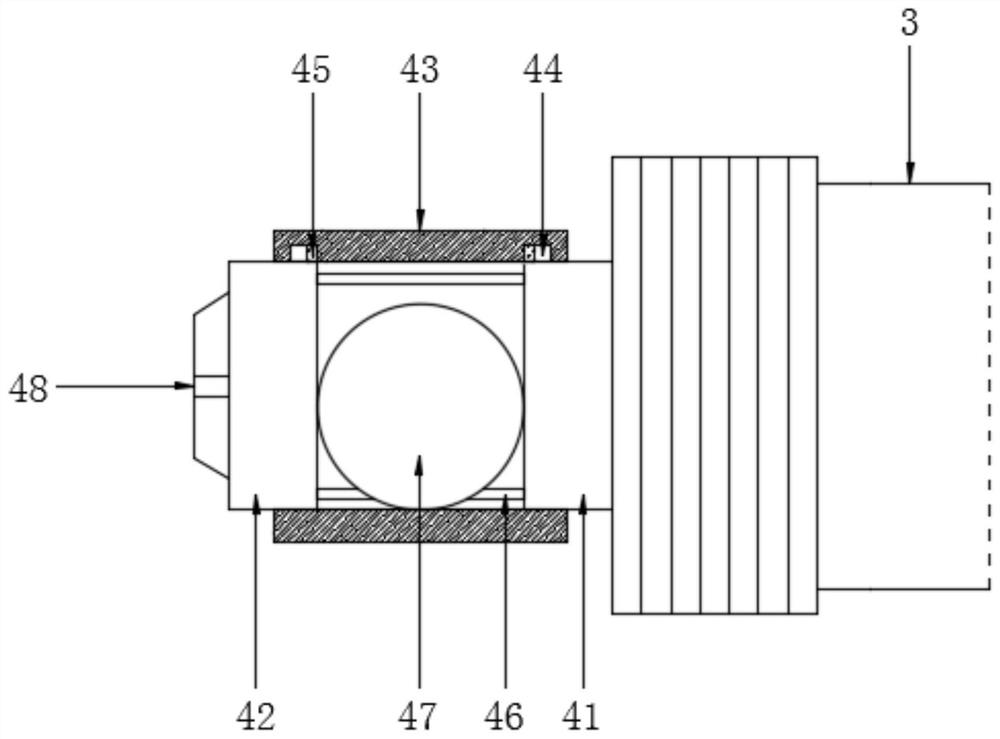

[0029] The present invention provides, for example Figure 1-7 An energy-saving motor with a heat dissipation function shown, comprising a front housing 1, the front housing 1 is provided with a stator, a rotor and a transmission shaft 3, both ends of the transmission shaft 3 run through the front housing 1 and extend to the outside of the front housing 1, the front housing 1 left end fixed provided with a rear housing 2, the drive shaft 3 left end extends to the interior of the rear housing 2, the rear housing 2 is provided with a trigger transmission mechanism 4, the transmission shaft 3 left end drives the trigger transmission mechanism 4 rotation, The trigger transmission mechanism 4 is provided with an air-cooled heat dissipation mechanism 5, the trigger transmission mechanism 4 and the air-cooled heat dissipation mechanism 5 is provided with a water-cooled heat dissipation mechanism 6, the crankshaft 53 in the air-cooled heat dissipation mechanism 53 rotates while driving the...

Embodiment 2

[0041] Different from the above embodiment, in the actual use of the above device, the technical personnel found that the temperature of the outer wall of the front housing 1 and the temperature of the left wall of the front housing 1 is too large, which in turn affects the overall heat dissipation efficiency of the device, in order to solve the above problems:

[0042] as Figure 1 and Figure 7 As shown, the front housing 1 is provided with an external heat dissipation mechanism 7, the external heat dissipation mechanism 7 comprises a heat sink 71 and a diversion pipe 72.

[0043] More specifically, the heat sink 71 fixed socket is provided on the outside of the front housing 1, the diversion pipe 72 is provided with a plurality, a plurality of the diversion pipe 72 is evenly distributed on the left side of the heat sink 71, and the right end of the diversion pipe 72 runs through the heat sink 71 and extends to the inside of the heat sink 71, the left end of the diversion pipe 72...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com