Electrode active material for alkali metal battery, electrode containing same, and alkali metal battery

An electrode active material, alkali metal battery technology, applied in battery electrodes, lithium storage batteries, secondary batteries, etc., can solve the problems of reduced positive active material mass, reduced capacity, low conductivity of positive active material, etc., to achieve high capacity, The effect of long charge and discharge life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] The preparation method of the electrode active material is not particularly limited as long as it is a method capable of compounding the raw materials. Here, examples of raw materials include sulfides of alkali metals, sulfides of transition metals such as V, and mixtures of salts of alkali metals and anion components.

[0090] As a composite method, mechanochemical treatment is preferable from the viewpoint of being able to synthesize a sample with a non-stationary composition and obtain a sample with low crystallinity.

[0091] The mechanochemical treatment is not particularly limited to the treatment apparatus and treatment conditions as long as each component can be uniformly reacted or compounded.

[0092] As a treatment device, a ball mill can generally be used. A ball mill is preferable because a large mechanical energy can be obtained. Among the ball mills, a planetary ball mill is preferable because the tank rotates on its own axis and the table revolves in a...

Embodiment 1

[0143] Li was metered in molar ratios of 93:7, 90:10, 81:19, 75:25, 70:30, 68:32, 67:33 and 59:41 2 S and V 2 5 3 , into the planetary ball mill. After the input, the mechanochemical treatment was carried out by a planetary ball mill, thereby obtaining 8 kinds of electrode active materials.

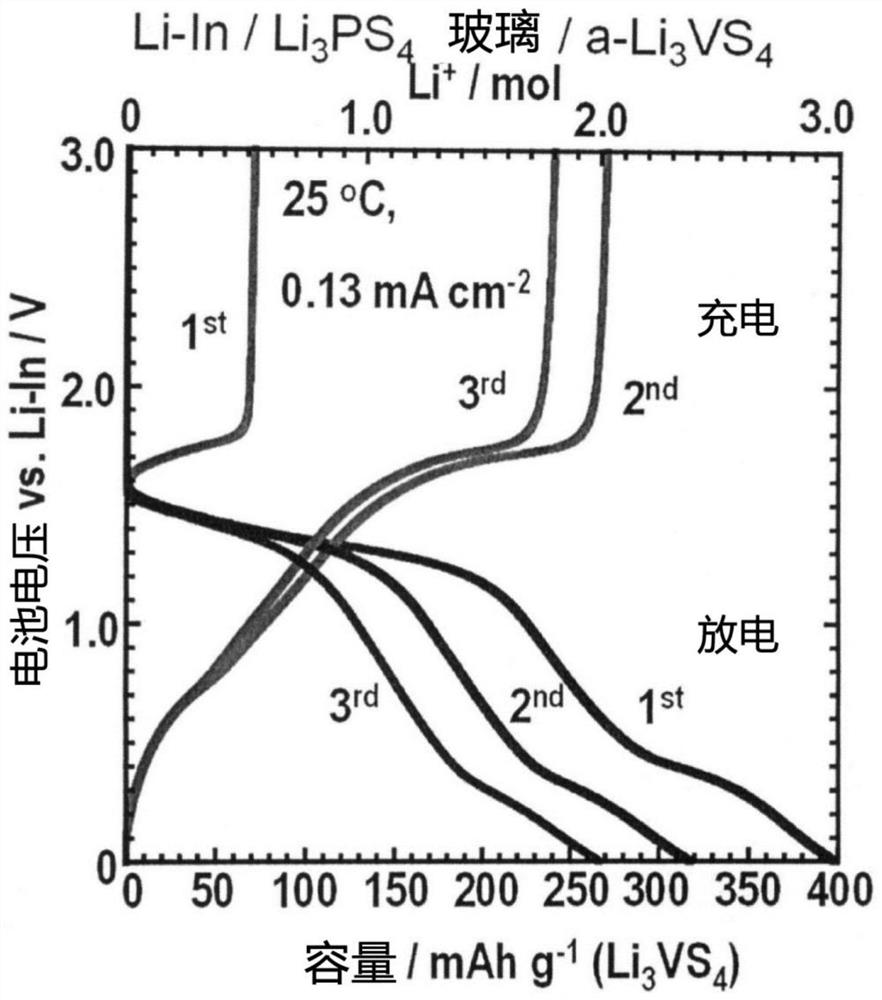

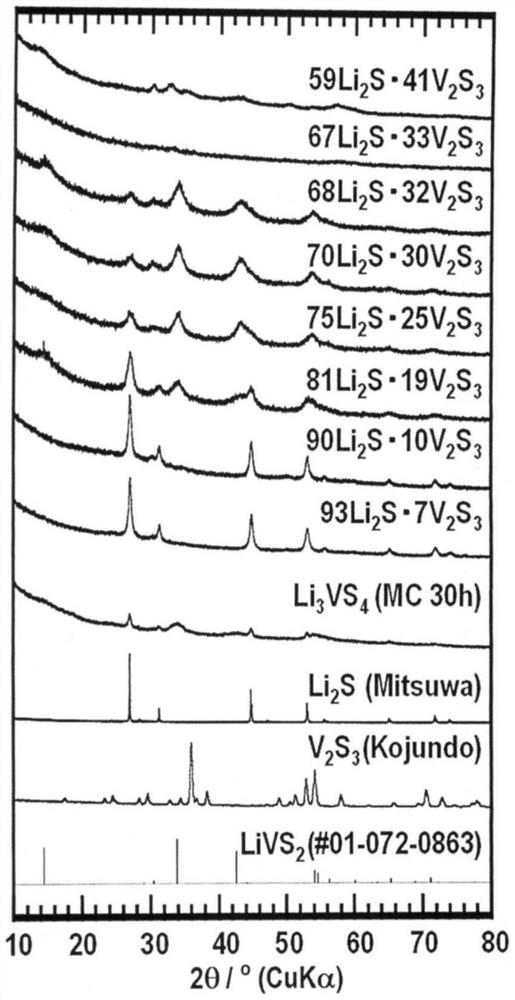

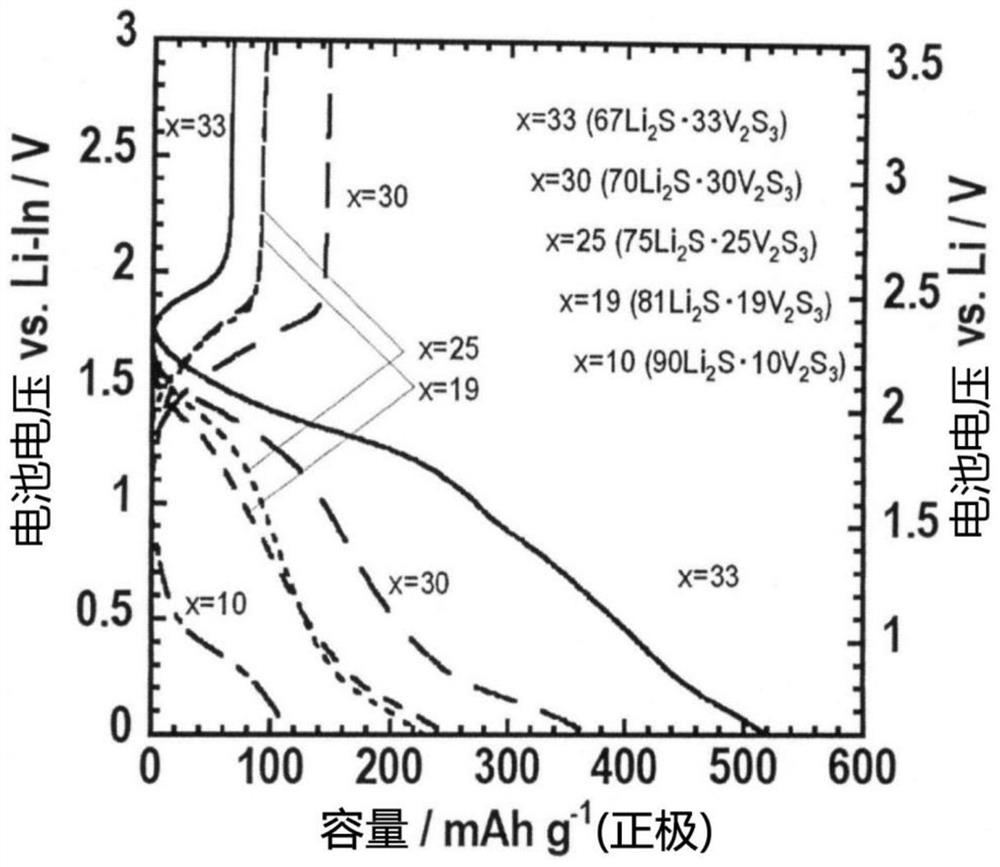

[0144] The planetary ball mill uses Pulverisette P-7 made by Fritsch, and the tank and balls are ZrO 2 It was prepared using a ball mill in which 500 (about 90 g) balls with a diameter of 4 mm were placed in a 45 ml can. The mechanochemical treatment was carried out in a dry argon glove box for 80 hours at an input amount of 0.3 to 0.5 g, a rotation speed of 510 rpm, and room temperature. The powder XRD patterns of 8 kinds of electrode active materials are as follows: figure 2 shown. exist figure 2 The lower part records Li 2 S, VS 3 and LiVS 2 The XRD pattern. Li 2 S and V 2 S 3 When the electrodes measured the electronic conductivity, they all showed 10% of the upper lim...

Embodiment 2

[0158] Except for Li 2 S, VS 3 and lithium salts (LiX: LiCl, LiBr, LiI or Li 2 SO 4 ) is measured into 67.5:22.5:10 molar ratio, obtains 4 kinds of electrode active materials (90(0.75Li 2 S 0.25V 2 S 3 )·10LiCl, 90(0.75Li 2 S 0.25V 2 S 3 )·10LiBr, 90(0.75Li 2 S 0.25V 2 S 3 )·10LiI and 90(0.75Li 2 S 0.25V 2 S 3 )·10Li 2 SO 4 ). Figure 6 The powder XRD patterns of 4 kinds of electrode materials are shown. exist Figure 6 The lower part records Li 2 S, VS 3 , LiI and LiVS 2 The XRD pattern. The numbers in the figure represent the numbers of the powder diffraction database JCPDS card.

[0159]Four types of pellets (positive electrode) having a diameter of 10 mm and a thickness of about 0.05 mm were obtained by pressing (pressure 360 MPa) 10 mg of the obtained electrode active material.

[0160] An all-solid battery was prepared in the same manner as in Example 1 except for using the above four kinds of positive electrodes, and the charge-discharge curve o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com