Variable-structure slag removal mechanism and method

A technology for removing slag and components, which is applied in the field of liquid metal slag removing mechanism, can solve problems such as increasing equipment cost, unsatisfied requirements for increased driving force, and easy failures, etc., so as to improve the service life of equipment, reduce the thermal protection level, prolong the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

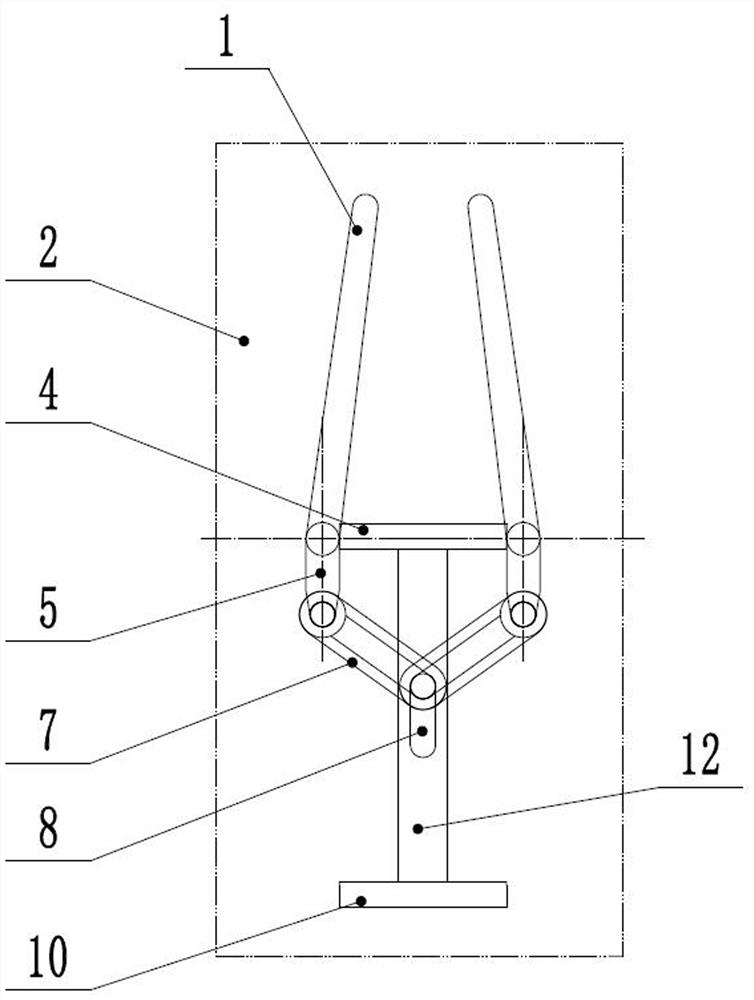

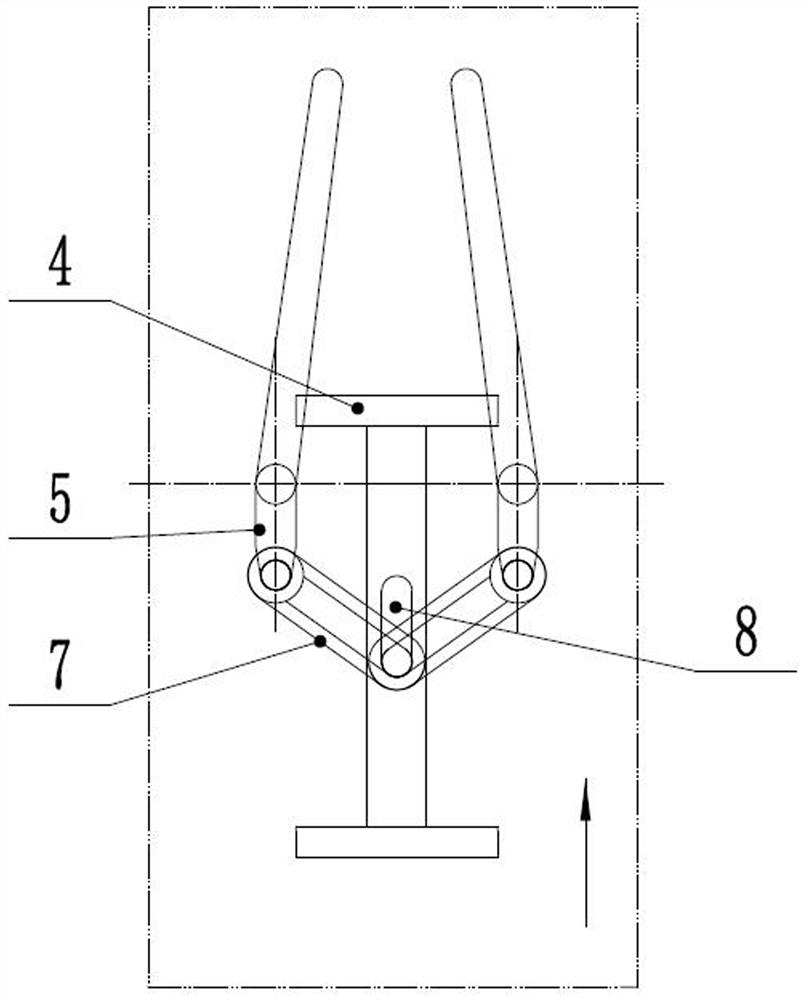

[0072] like Figure 1-10 , in this embodiment, the pulling member 7 is a rigid structural member provided with a sliding groove, the movable connection point between the crank 5 and the pulling member 7 and the movable connection point between the driving body 12 and the pulling member 7, two Or at least one of them is in the sliding groove (the end that is not in the sliding groove can be a common hinge), so that the crank 5 or the driving body 12 can rotate relative to the pulling member 7, and can also move relative to it, thereby After the front push block 4 or the rear push block 10 touches the crank 5, relative movement can occur between the movable connection point between the crank 5 and the pulling member 7 and the movable connection point between the driving body 12 and the pulling member 7 .

[0073] Further, the drive body 12 is provided with a chute 8, and the chute 8 is provided with a hinge shaft that can move back and forth along the chute 8, and the other end...

Embodiment 2

[0079] like Figure 11-22 , The difference between this embodiment and Embodiment 1 is that the pulling member 7 is a flexible member, such as a soft belt. The flexible belt can be ring-shaped or rod-shaped. If it is ring-shaped, the active connection points at both ends are in this ring-shaped groove (shaft-groove connection), and if it is not ring-shaped, both ends can be hinged.

[0080] The function of the soft belt is: after the front push block 4 or the rear push block 10 touches the crank 5, if there is a problem of mechanical interference, the soft belt (pull member 7) can be bent to make the distance between the crank 5 and the pull member 7 Relative movement can occur between the movable connection point and the movable connection point between the driving body 12 and the pulling member 7, thereby resolving the interference, so that the crank 5 moves completely under the action of the push block.

[0081] Another difference between this embodiment and Embodiment 1 i...

Embodiment 3

[0088] The concept of this embodiment is quite different from the above embodiments: the pulling member 7 is a rigid connecting rod, and both ends are hinged, but the hinge shaft connected to the end of the driving body 12 is along the drive The chute 8 on the body 12 is movable, and in order to ensure normal pulling, the driving body 12 is also provided with an elastic mechanism.

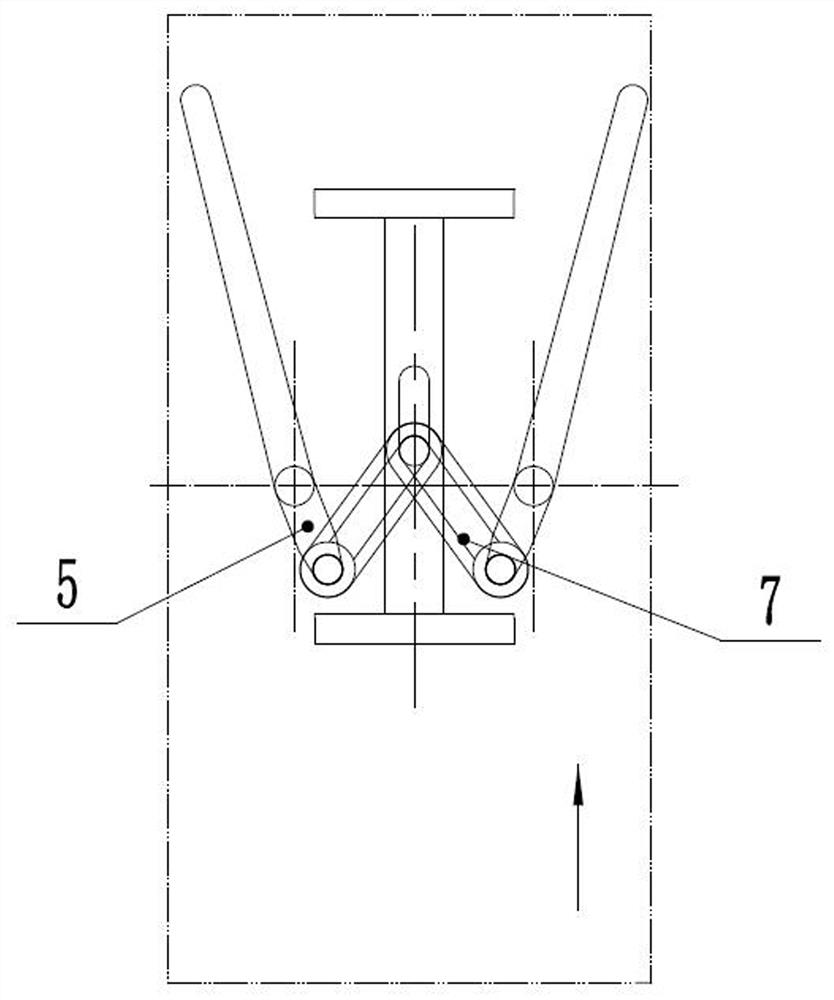

[0089] Specifically, such as Figure 23 , The driving body 12 is also provided with a chute 8 running forward and backward, and two groups of slag pickers 1 , pulling members 7 and cranks 5 are arranged symmetrically with respect to the chute 8 . The other ends of the two pulling members 7 are connected to the hinge shafts arranged in the chute 8 to realize the respective rotation of the two pulling members 7 relative to the chute 8 and the forward and backward movement of the hinge shaft along the chute 8 .

[0090] The driving body 12 is also provided with a front spring 3 , a front push plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com