Natural texture decorative rock plate and preparation method thereof

A decorative rock and texture technology, which is applied in the manufacture of tools, ceramic material production, ceramic molding machines, etc., can solve the problems that the texture is not clear and realistic, the pattern is not natural and rich, and the pattern control of the glaze process is difficult, so as to achieve a clear and realistic texture effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

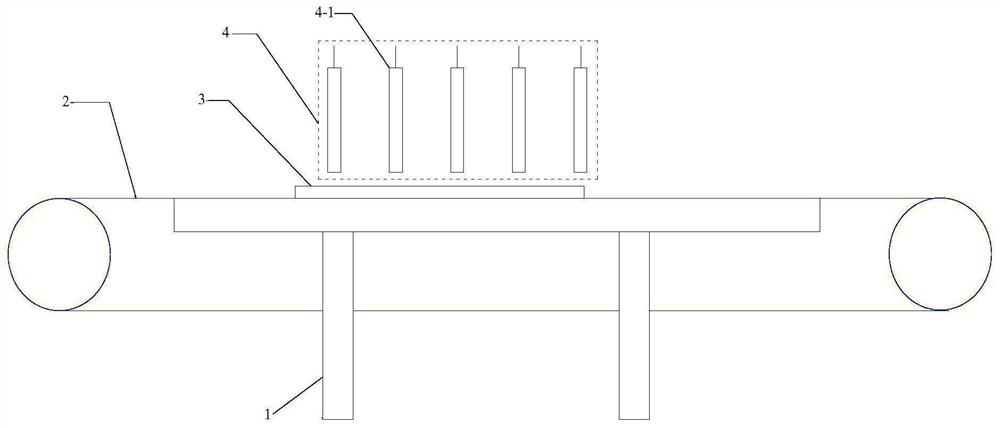

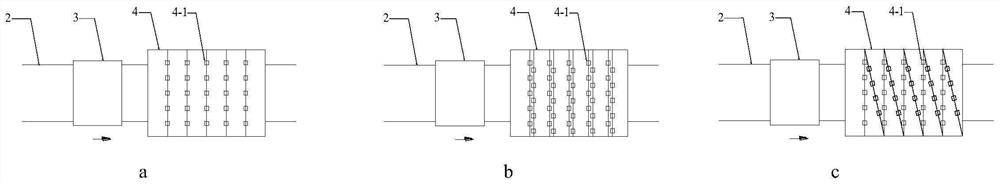

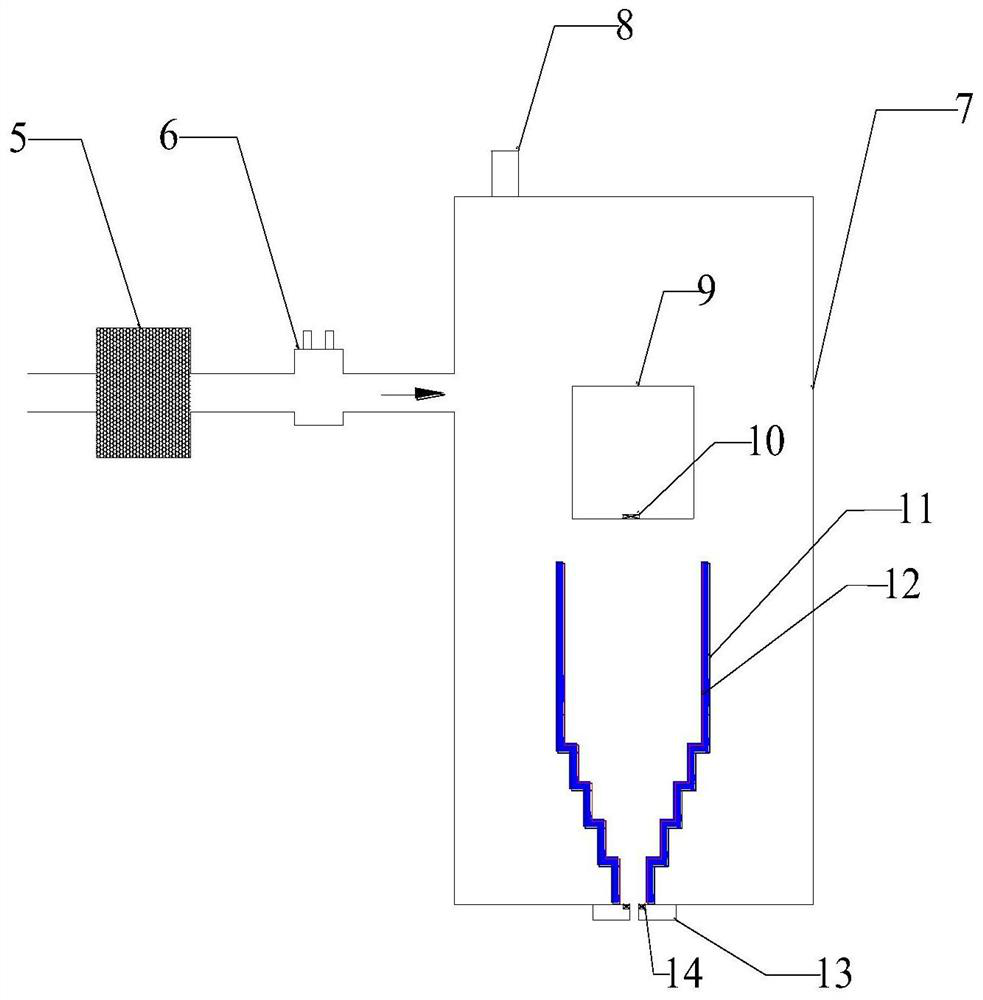

[0075] like Figure 1-11 Shown, the present invention adopts following steps to realize:

[0076] A, prepare green body powder according to conventional methods, and set aside;

[0077] B. Preparation of slurry for digital slurry system: Weigh mineral raw materials according to the designed chemical composition of slurry for digital slurry system, add a certain proportion of debonding agent, suspending agent, colorant, and water for ball milling to prepare two A kind of slurry for colored digital pulp system with different chemical composition: the chemical composition of the slurry for digital pulp system is calculated by weight percentage: SiO 2 45%, Al 2 o 3 16%, CaO 11%, MgO 8%, K 2 O 1.5%, Na 2 O 3%, BaO 3%, ZnO 3%, B 2 o 3 0.5%, Fe 2 o 3 ≤0.5%, TiO 2 ≤0.3%, loss on ignition ≤12%, the firing temperature of this slurry for digital slurry system is relatively low, and can be used to form a transparent bright glaze effect. The chemical composition of another slur...

Embodiment 2

[0088] like Figure 1-11 Shown, the present invention adopts following steps to realize:

[0089] A, prepare green body powder according to conventional methods, and set aside;

[0090] B. Preparation of slurry for digital slurry system: Weigh mineral raw materials according to the designed chemical composition of slurry for digital slurry system, add a certain proportion of debonding agent, suspending agent, colorant, and water for ball milling to prepare two A kind of slurry for colored digital pulp system with different chemical composition: the chemical composition of the slurry for digital pulp system is calculated by weight percentage: SiO 2 50%, Al 2 o 3 12%, CaO 15%, MgO 5%, K 2 O 3%, Na 2 O 1.5%, BaO 7%, ZnO 1%, B 2 o 3 3%, Fe 2 o 3 ≤0.5%, TiO 2 ≤0.3%, loss on ignition ≤12%, the firing temperature of this slurry for digital slurry system is relatively low, and can be used to form a transparent bright glaze effect. The chemical composition of another slurry...

Embodiment 3

[0102] like Figure 1-11 Shown, the present invention adopts following steps to realize:

[0103] A, prepare green body powder according to conventional methods, and set aside;

[0104] B. Preparation of slurry for digital slurry system: Weigh mineral raw materials according to the designed chemical composition of slurry for digital slurry system, add a certain proportion of debonding agent, suspending agent, colorant, and water for ball milling to prepare two A kind of slurry for colored digital pulp system with different chemical composition: the chemical composition of the slurry for digital pulp system is calculated by weight percentage: SiO 2 47%, Al 2 o 3 14%, CaO 13%, MgO 6%, K 2 O 2%, Na 2 O 2.5%, BaO 5%, ZnO 2%, B 2 o 3 2%, Fe 2 o 3 ≤0.5%, TiO 2 ≤0.3%, loss on ignition ≤12%, the firing temperature of this slurry for digital slurry system is relatively low, and can be used to form a transparent bright glaze effect. The chemical composition of another slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com