High-efficiency flatness detection device for engineering survey

A detection device and flatness technology, applied in measurement devices, mechanical measurement devices, and mechanical devices, etc., can solve the problems of waste of manpower and material resources, low detection efficiency, limited detection area of laser detection devices, etc., and achieve time reduction and rapid detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

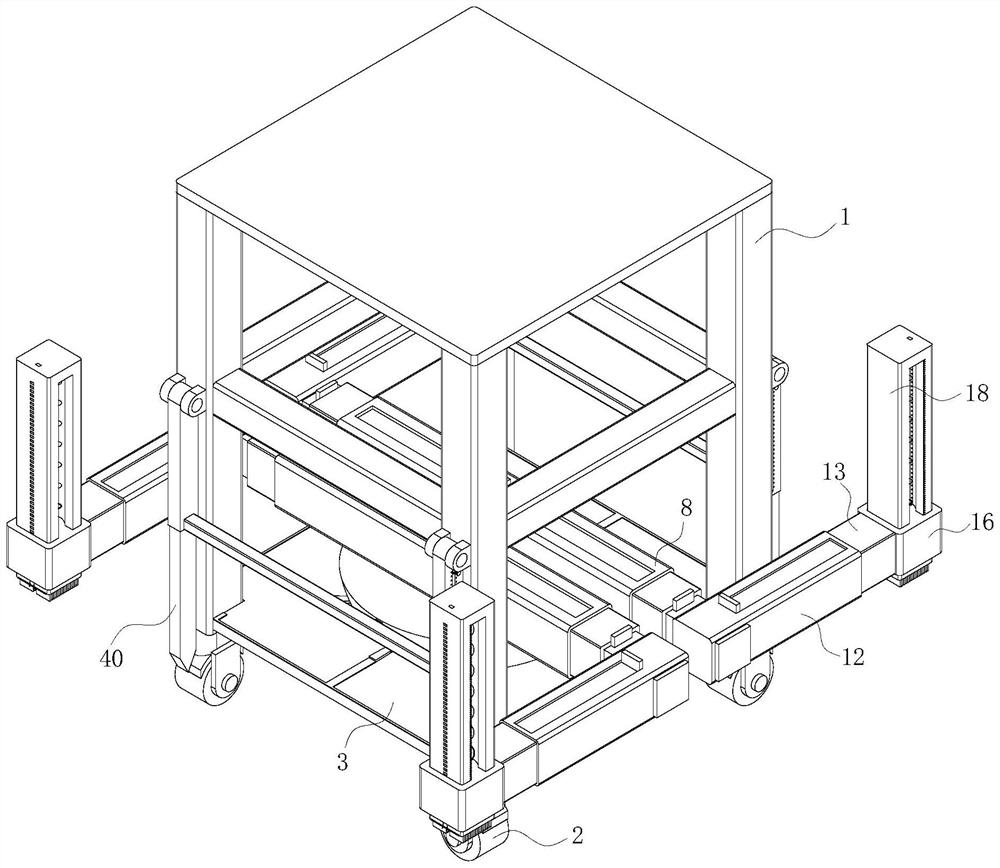

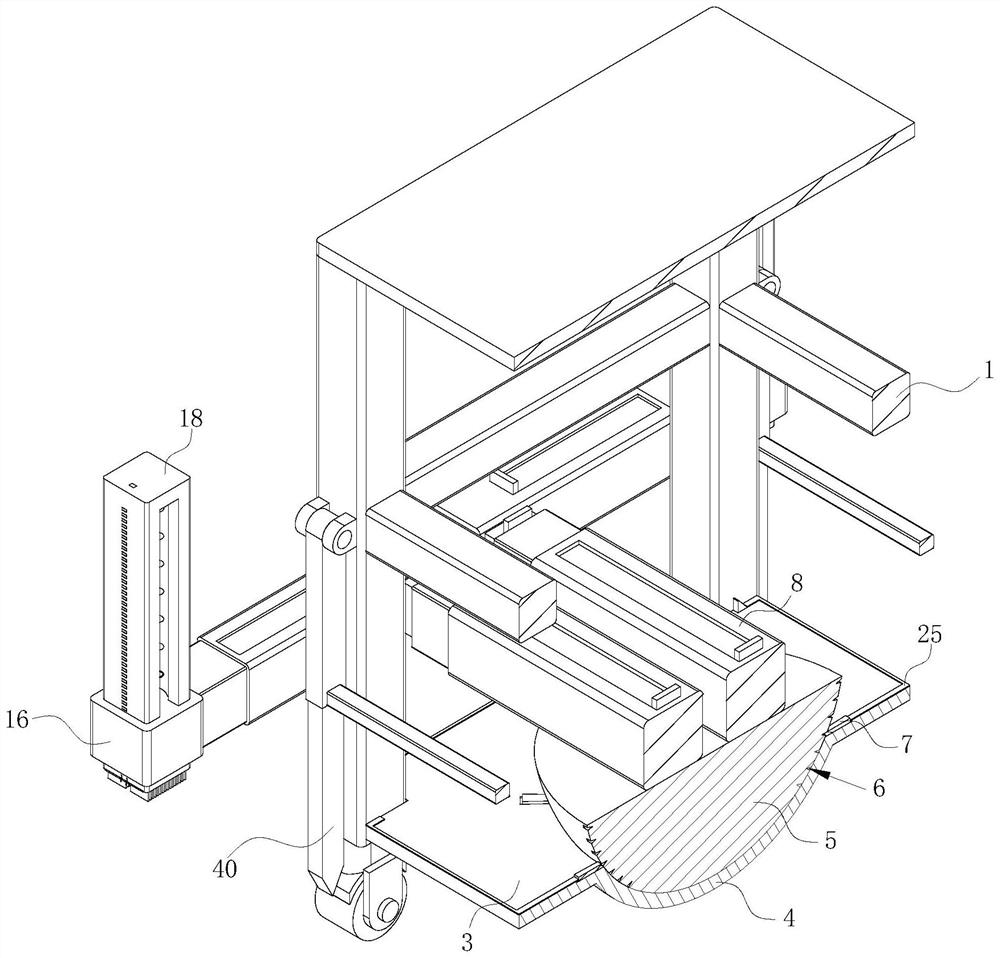

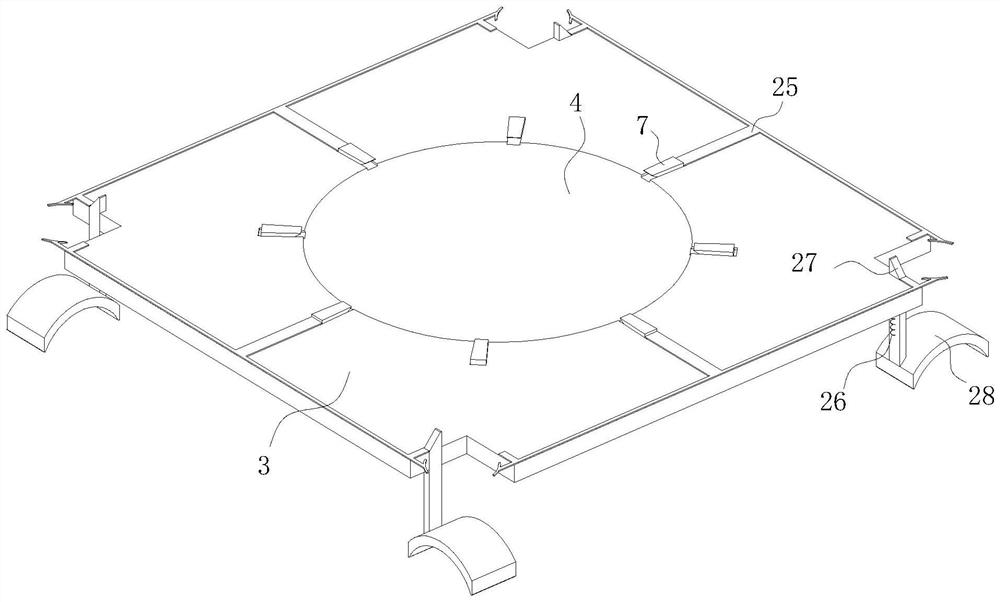

[0035] see Figure 1-15 , the present invention provides a technical solution: a flatness detection device for high-efficiency engineering survey, including a mounting frame 1, the four corners of the bottom of the mounting frame 1 are provided with rolling wheels 2, and the middle position of the mounting frame 1 is fixedly connected with a mounting Plate 3, the outside of mounting frame 1 is provided with a plurality of identical detection mechanisms, and the detection mechanism can detect the height of the construction ground at the positions of multiple detection mechanisms, and an adjustment mechanism is provided between the detection mechanism and the installation plate 3, and the adjustment mechanism can Adjust the position of the detection mechanism, the surface of the mounting plate 3 is provided with a horizontal mechanism that can keep the adjustment mechanism and the detection mechanism horizontal;

[0036] The horizontal mechanism includes an arc-shaped installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com