System and method for detecting bending degree of sublance of steelmaking converter

A bending degree, steel-making converter technology, applied in the field of metallurgy, can solve the problems such as failure to detect the bending of the auxiliary gun in time, damage to the auxiliary gun, etc., and achieve the effect of reducing the probability of personal injury, reducing the workload, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

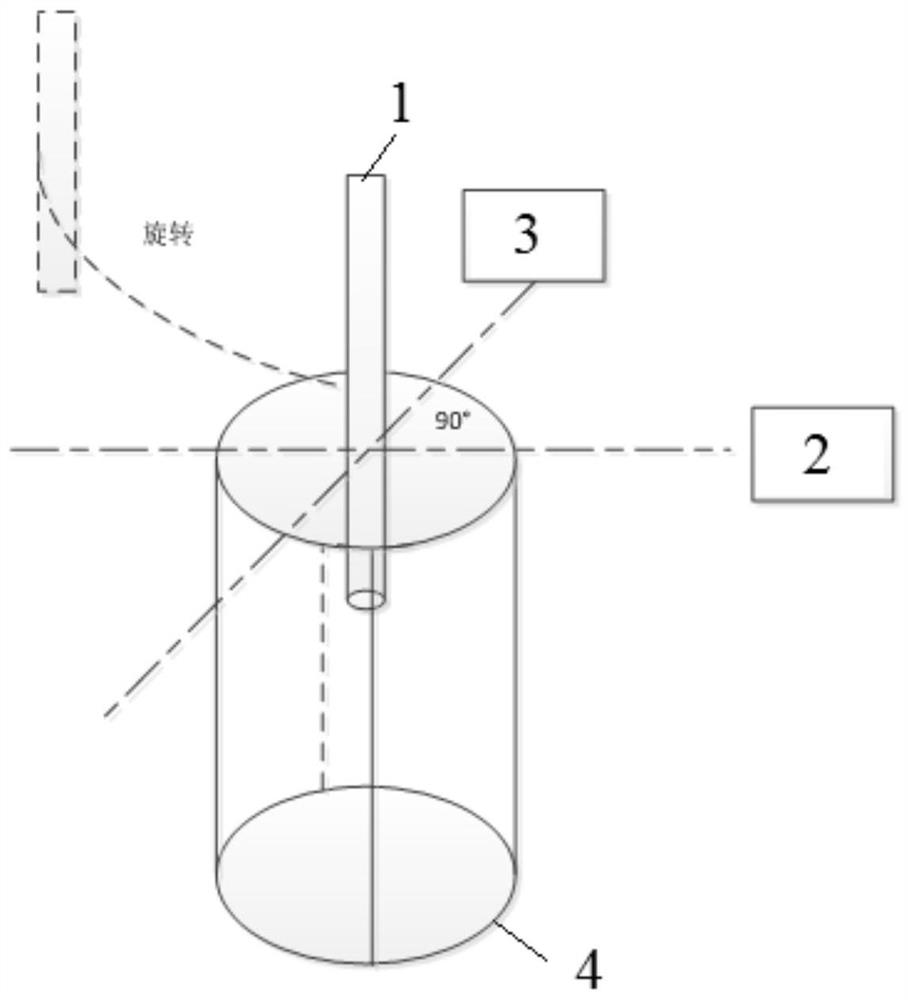

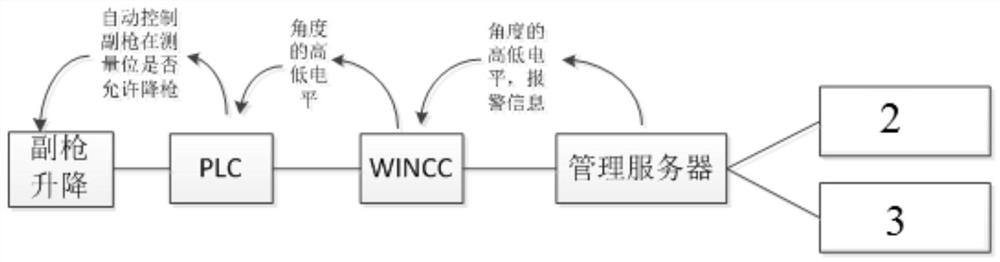

[0049] Such as figure 1 As shown, on the one hand, the embodiment of the present application provides a detection system for the bending degree of the steelmaking converter sub-lance, including: sub-lance probe 1, measuring position limiter, signal acquisition device, signal processing device and signal control device, sub-lance The probe 1 is connected to the connector of the sub-gun; the measurement limit is used to limit the sub-gun probe 1 on the measurement position; the signal acquisition device is used to collect the image information of the sub-gun probe 1; the signal processing device is used to receive the image information, The image display interface is obtained after analyzing the image information, and then the analysis result is output; the signal control device is used to automatically control whether the auxiliary gun at the measurement position continues to perform gun lowering operation according to the analysis result.

[0050] Wherein, the signal acquisiti...

Embodiment 2

[0058] On the other hand, the embodiments of the present application provide a method for detecting the bending degree of the sub-lance of the steelmaking converter, which is applied to the detection system for the degree of bending of the sub-lance of the steelmaking converter, including:

[0059] Step S1: before the sub-gun is put into use, collect the standard image information of the sub-gun probe 1;

[0060] Step S2: After the sub-gun is put into use, collect the contrast image information of the sub-gun probe 1;

[0061] Step S3: comparing and analyzing the comparison image information with the standard image information to obtain an analysis result;

[0062] Step S4: According to the analysis result, it is automatically controlled whether to continue to lower the gun of the auxiliary gun at the measuring position.

[0063] Among them, step S1: before the sub-gun is put into use, collecting the standard image information of the sub-gun probe 1 includes:

[0064] Step S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com