Wax deposition simulation device and method

A simulation device and simulation method technology, applied in the investigation stage/state change and other directions, can solve the problems of deviation of wax deposition results, single type of wax deposition cylinder, and low accuracy of simulation experiments, so as to reduce experimental deviation and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

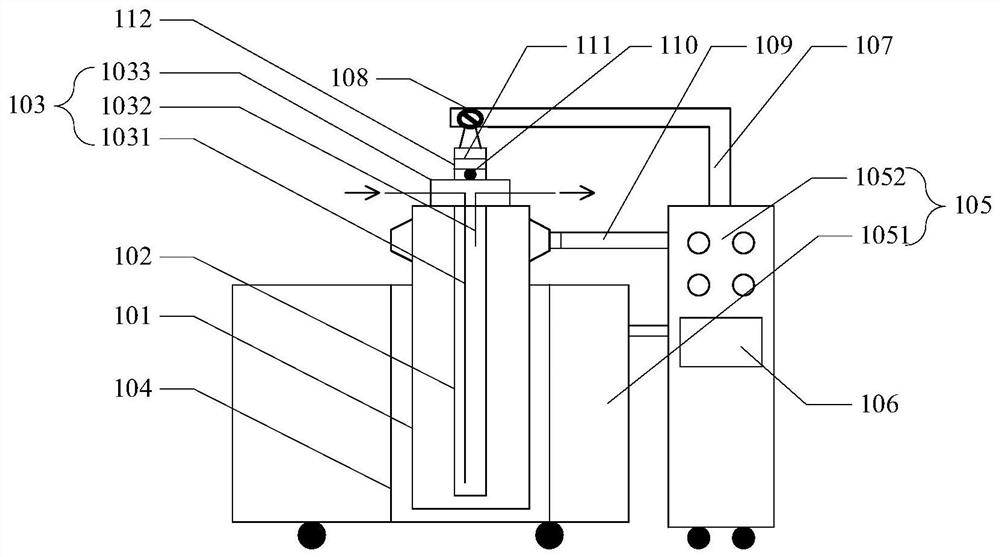

[0039] figure 1 It is a schematic structural diagram of a wax deposition simulation device provided in an embodiment of the present application. Such as figure 1 As shown, the wax deposition simulation device includes a sample outer cylinder 101, a replaceable wax deposition inner cylinder 102, and a cooling assembly 103 for cooling the wax deposition inner cylinder 102, wherein the wax deposition inner cylinder 102 is adapted to the properties of the inner wall of the pipeline , the wax deposition inner cylinder 102 is placed in the sample outer cylinder 101 , and the cooling assembly 103 is installed on the wax deposition inner cylinder 102 .

[0040] The cooling assembly 103 comprises a coolant inlet pipe 1031, a coolant out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com