Event-oriented transmission of process measurements

A process measurement and event technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve problems such as huge overhead, and achieve the effect of reproducing and simplifying configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

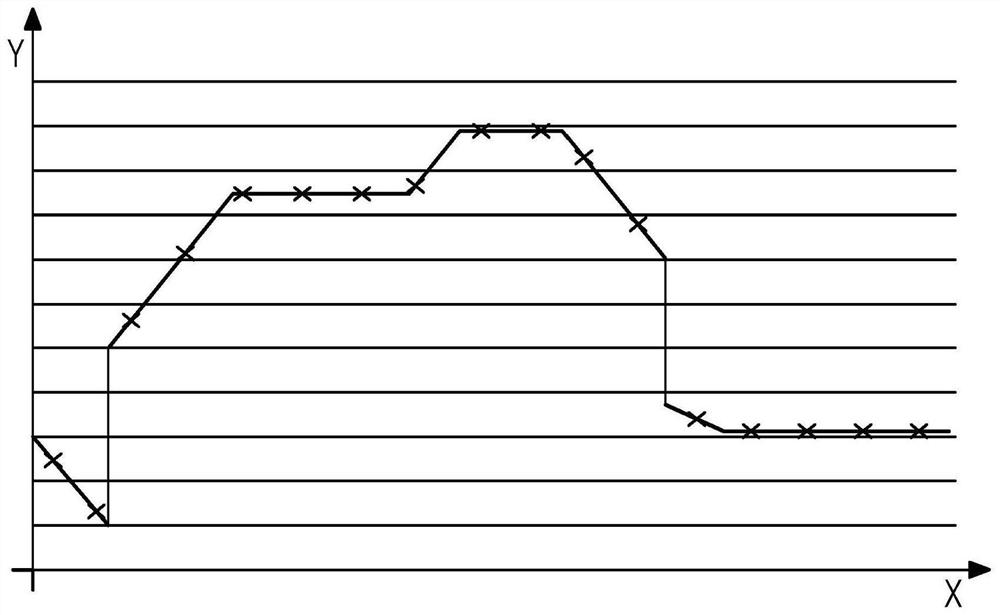

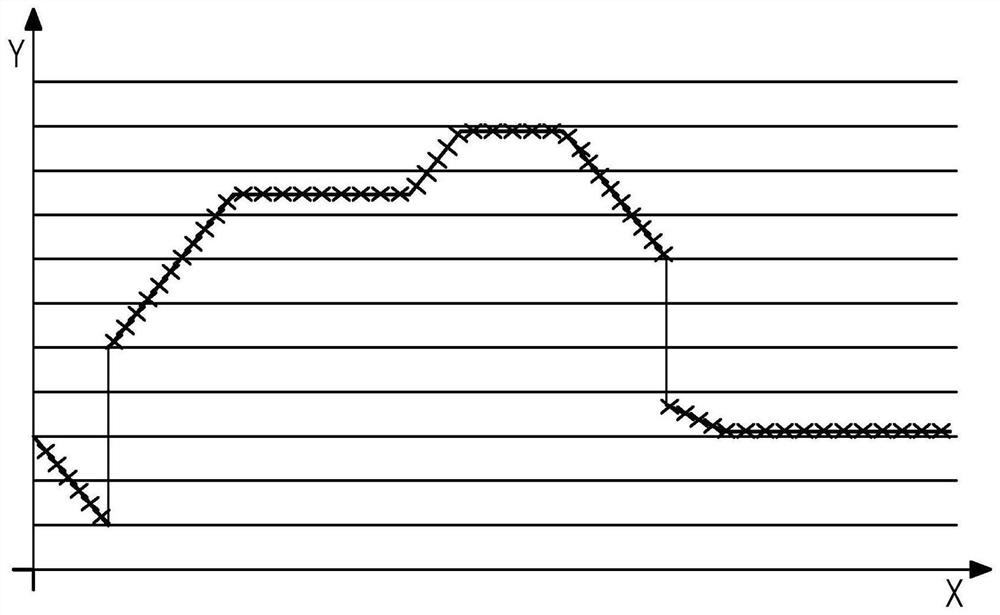

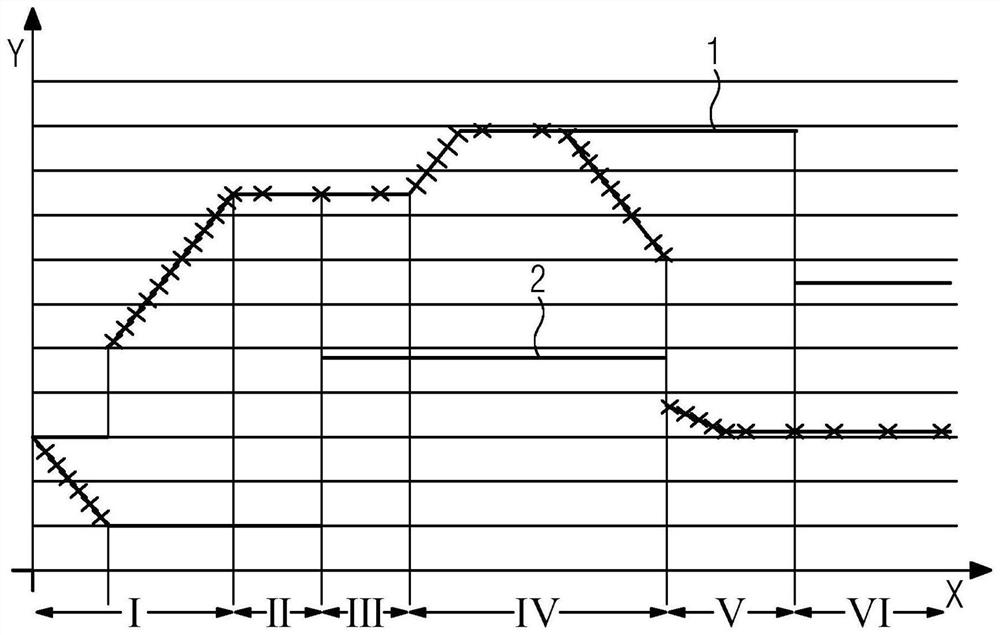

[0037] figure 1 Exemplary process curves are shown for process measurements in an XY graph with arbitrary units. Process measured values are processed cyclically in automation devices. The amount of process measurement values should be thinned out before transmission to the operator station server of the control system, so that each individual process measurement value does not have to be transmitted.

[0038] The method of event-oriented transmission is used according to the prior art, which employs fixedly configured measuring ranges, minimum and maximum transmission rates, and thresholds for hysteresis. in accordance with figure 1 Process measured values are marked with a cross in the process curve of , which were selected by known methods for transmission from the automation system to the operator station server. It can be seen that a good reduction is achieved with a measuring range configured with strong thinning. However, the reproduction of the process curve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com