Construction waste sorting equipment

A sorting technology for construction waste, which is applied in solid separation, separation of solids from solids with airflow, and recycling of furniture waste. The effect of high wind strength and stability, and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

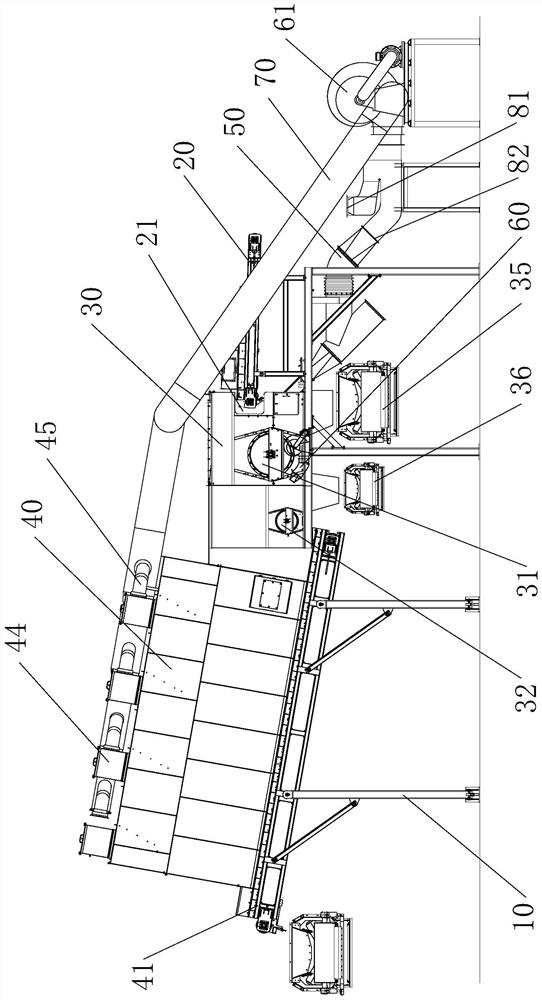

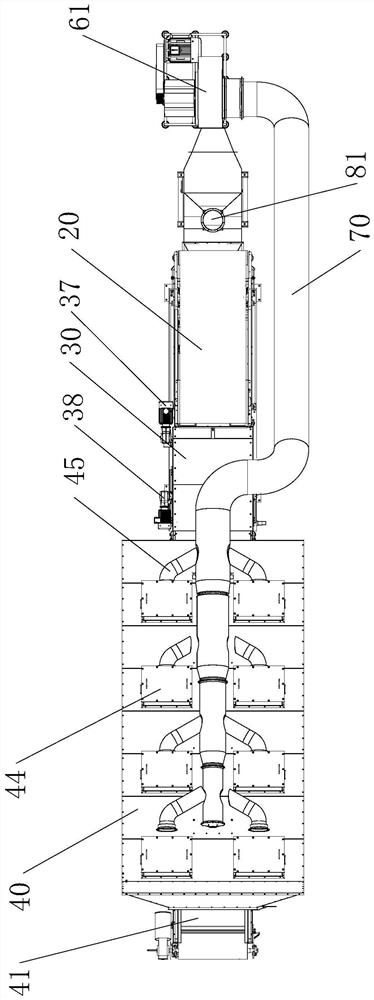

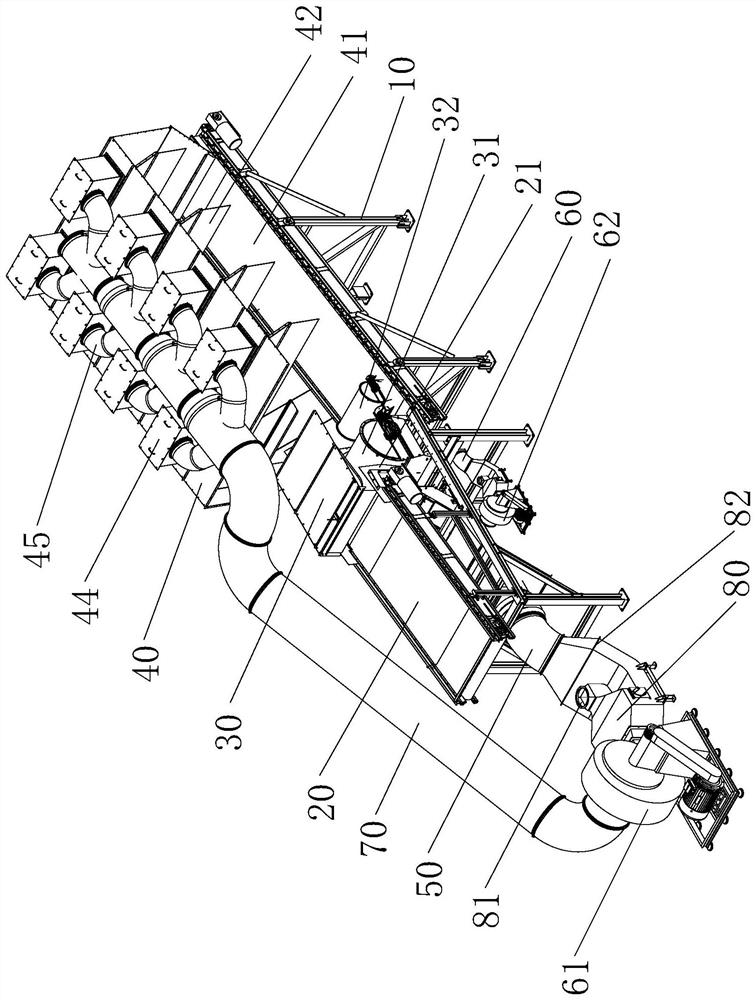

[0047] like Figure 1-Figure 4As shown, this embodiment provides a construction waste sorting equipment, including a frame 10, and the frame 10 is provided with a first belt conveyor 20, a material distribution box 30 and a settling box 40 that are connected in a straight line in sequence, wherein the first belt conveyor 20 The belt conveyor 20 is a conventional conveyor, which can be directly purchased from the market.

[0048] The discharge end of the first belt conveyor 20 penetrates into the distributing box 30 and is located at the upper part of the inner cavity of the distributing cavity 30. The distributing box 30 is rotatably connected with a first dispersing roller 31 for driving the first dispersing roller The first dispersing motor 37 rotated by 31, the second dispersing roller 32 located on the side of the first dispersing roller 31 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap