Pressing tool for welding valve seat of swing check valve

A check valve and swing-type technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effects of simple production, convenient use, and large reduction in welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

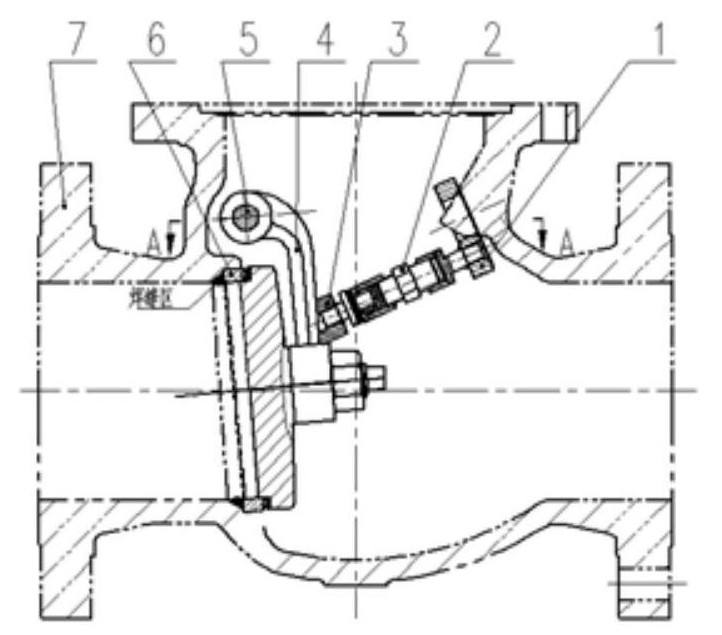

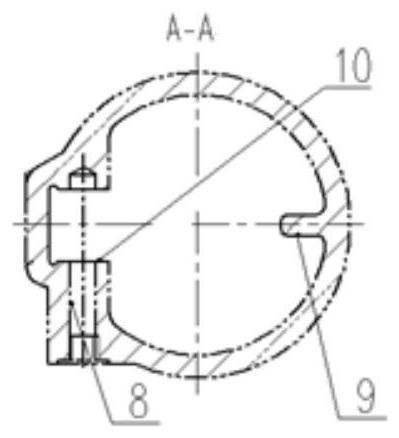

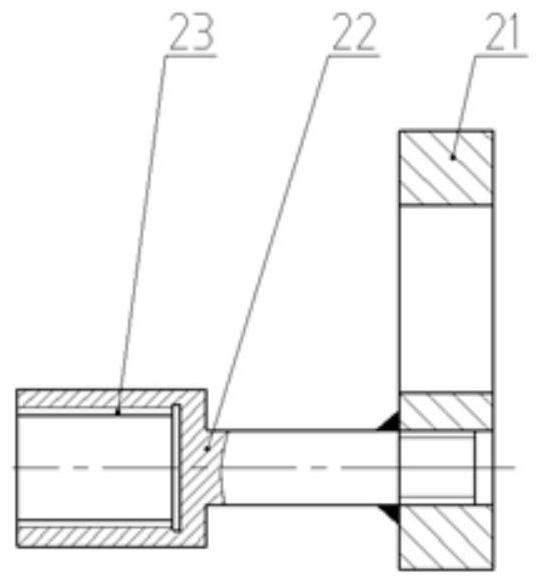

[0027] A pressing tool for a welded valve seat of a swing check valve, comprising a positioning plate assembly, a locking screw, a pressing block assembly, a rocker assembly and a pin shaft; the positioning plate assembly is assembled by a positioning plate and a connecting rod Welding composition; there is a waist-shaped slot hole and a threaded hole on the positioning plate; the small end of the connecting rod has a thread, and the center of the large end has a left-handed threaded hole, and the threaded hole is used to lock the screw. A section of left-handed thread ends are connected; the two ends of the locking screw are respectively provided with a section of threads with equal specifications but opposite directions of rotation, with a section of hexagonal square body in the middle; the compression block assembly includes a compression block, a compression block It is composed of connecting rod, 2 disc springs, movable nut, inner hexagon screw and key; one end of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com