Forming process of ultra-large marine flange

A super-large ship and forming process technology, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of difficult processing, large welding deformation, large residual stress, etc., to reduce manufacturing difficulty and cost, Effects of reduced requirements for processing conditions, good dimensional accuracy, and shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

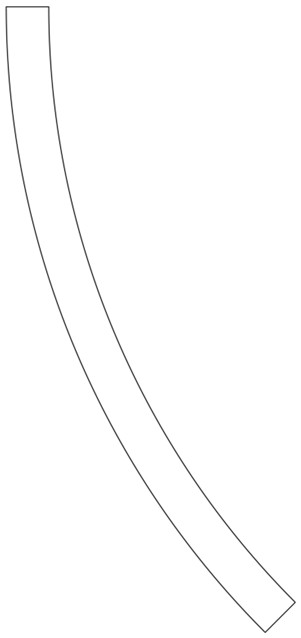

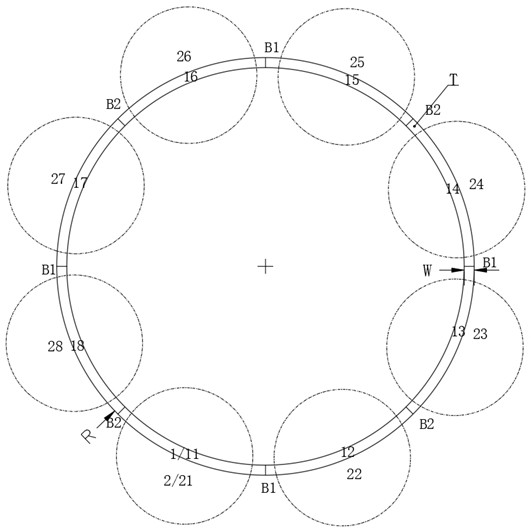

[0046] The super-large marine flange disclosed in the present invention is applied to a 3200T jack-up wind power installation vessel to be used as a rotating support for performing hoisting operations. The specific parameters of the super-large marine flange are as follows: the material is ASTM A694 (-40 ℃ CVN), the outer diameter R is greater than 20m, the radial width W is greater than 450mm, and the thickness T is greater than 200mm (such as figure 2 shown in).

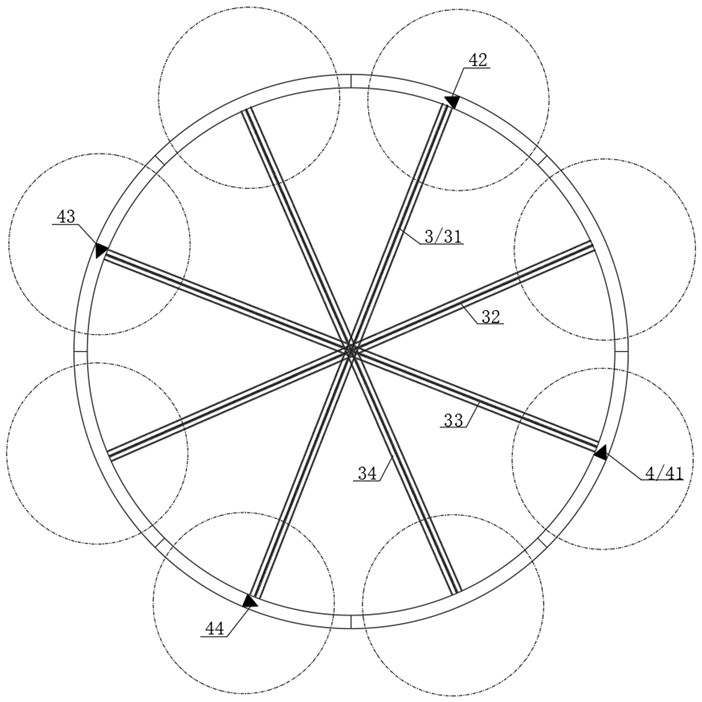

[0047] The content disclosed in the present invention will be further described in detail below with reference to the specific embodiments, the main idea is that the super-large marine flange is assembled and welded by 8 equal-length arc flange segments. The forming process of super-large marine flange includes the following steps:

[0048] S1, setting out nesting stage, which includes the following sub-steps:

[0049] S11. According to the design blueprint of the super-large marine flange 1, it is equally divid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com