Automatic welding method for butt joint of stainless steel pipes

A stainless steel pipe, automatic welding technology, applied in the direction of welding equipment, welding/welding/cutting items, applications, etc., can solve the problem of large deformation of stainless steel welding, to solve the problem of large welding deformation, ensure consistency, overcome size errors and assembly The effect of poor precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

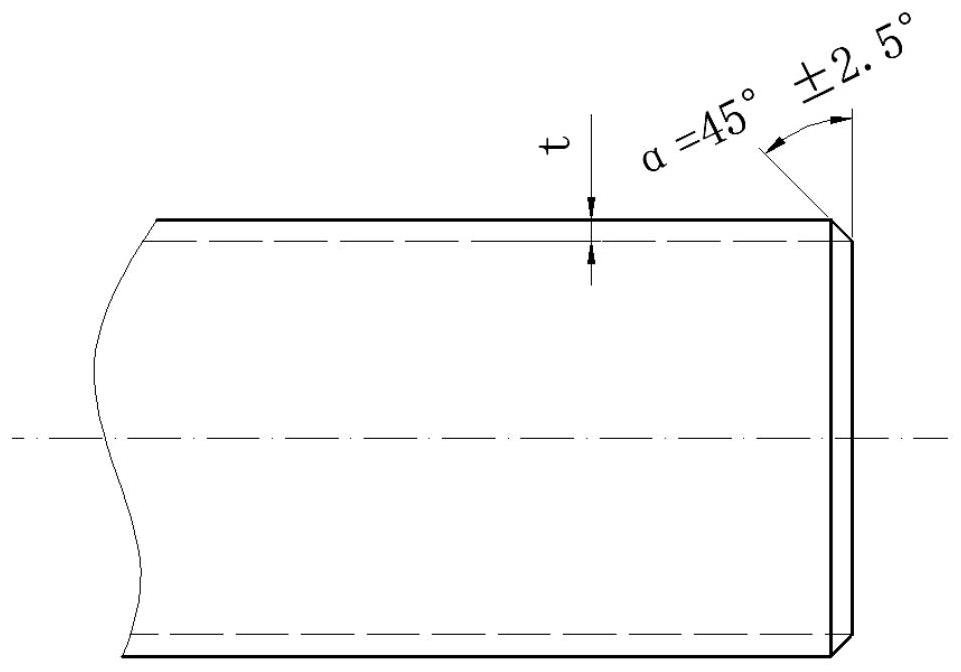

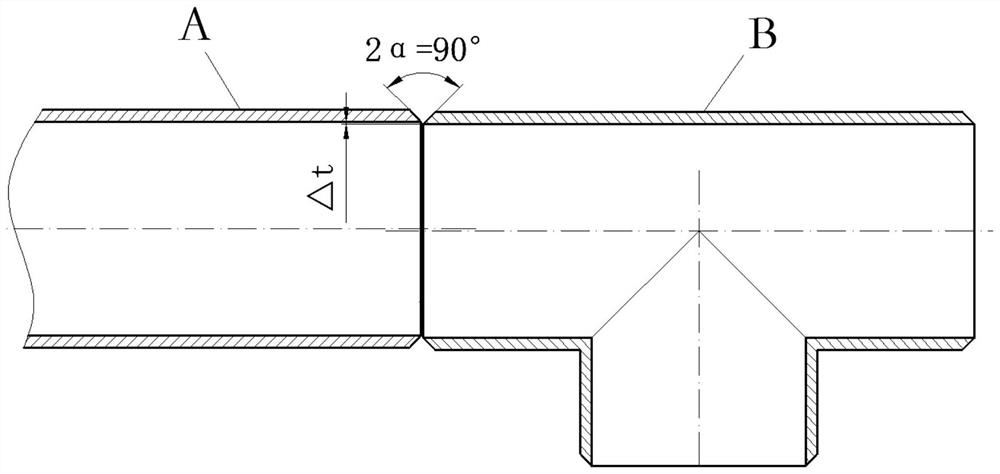

[0042] The present invention is used for automatic welding of butt joints of stainless steel pipes; please refer to figure 1 , Before the welding of stainless steel pipe fittings with wall thickness t, a V-shaped groove should be machined at the end, and the unilateral angle α of the V-shaped groove is 45°±2.5°; refer to figure 2 , the pipe fittings A and B to be butted form a full V-shaped bevel at the butt joint, and the bevel angle is 2α=90°.

[0043] The main principle of the automatic welding method for butt joint of stainless steel pipes according to the present invention is as follows:

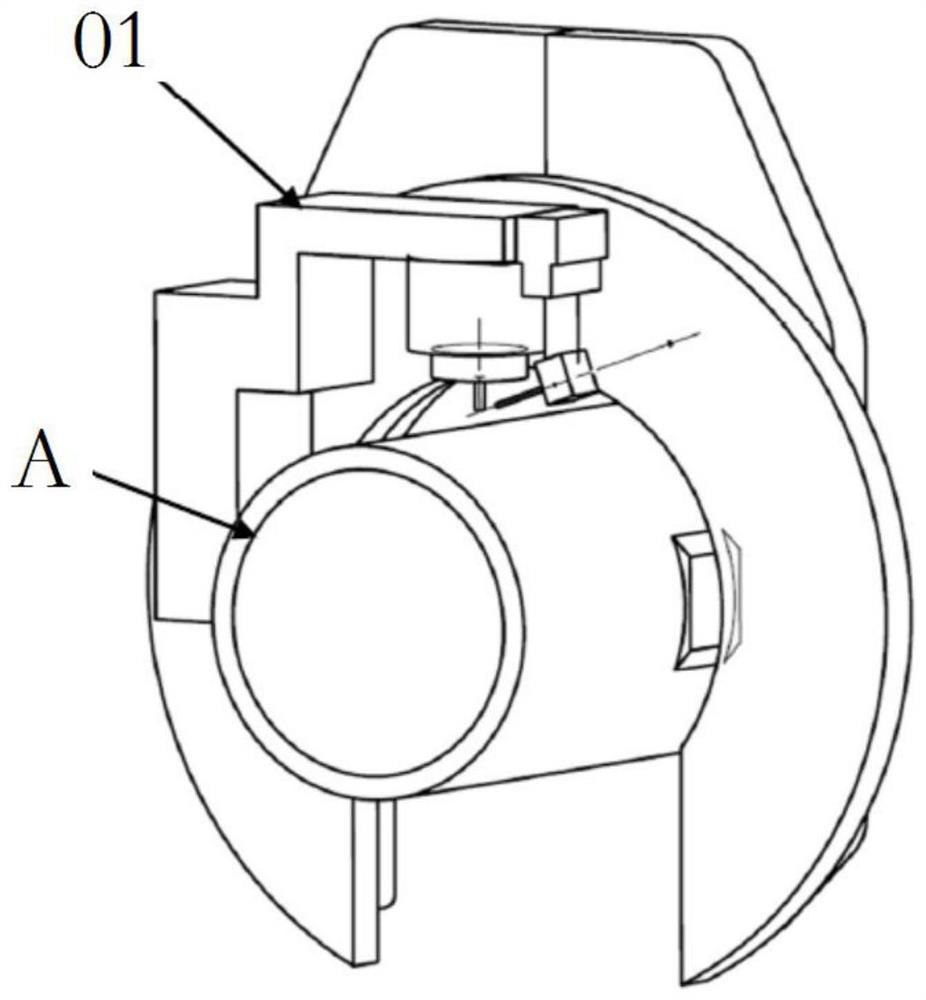

[0044] 1. Use automatic pipe and pipe welding tongs to complete all-position butt welding of stainless steel pipes.

[0045] 2. Using pulse argon arc welding technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com