Automatic punching device for cabinet door

A technology of punching device and cabinet door, which is applied to manufacturing tools, wood processing appliances, fixed drilling machines, etc., can solve the problems of easy accumulation and residue, and achieve the effect of preventing scattering and fast feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

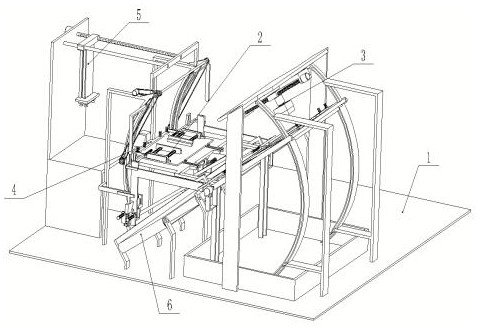

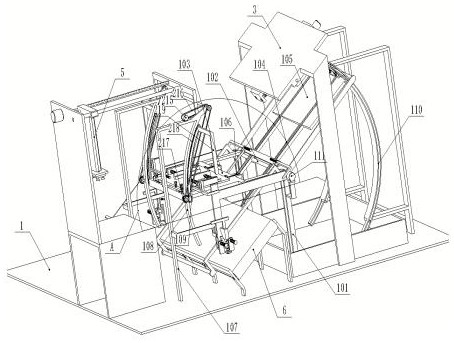

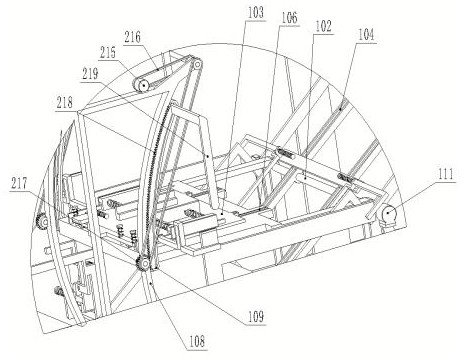

[0033] as Figures 1 to 11As shown, a cabinet door automated punching device, comprising a base 1, fixed on the base 101 and an auxiliary bracket 107, rotating on the main bracket 101 connected to the horizontal shaft 102, on the horizontal axis 102 provided with a clamping base plate 103 and a long slide 104, fixed at one end of the long slide 104 drilled bottom plate 105, fixed on the clamping bottom plate 103 with a long slide 104 matching short slide 106; under the auxiliary bracket 107 fixed curved slide 108, On the curved slide 108 is provided with a circular curved slide 109, one end of the clamping bottom plate 103 is superimposed within the first annular curved slide 109; sliding on the clamping base plate 103 is provided with a pair of cabinet plate clamping device 2, the cabinet plate clamping device 2 can slide on the short slide 106 and the long slide 104; the drilling bottom plate 105 is provided with a drilling device 3 directly above the drilling bottom plate 105, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com