Injection mold with umbrella-shaped cooling water channel

A cooling waterway and injection mold technology, applied in the field of molds, can solve the problems of poor cooling effect, increased cost, small contact area of cooling surface, etc., and achieve the effect of improving structural strength and reducing production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

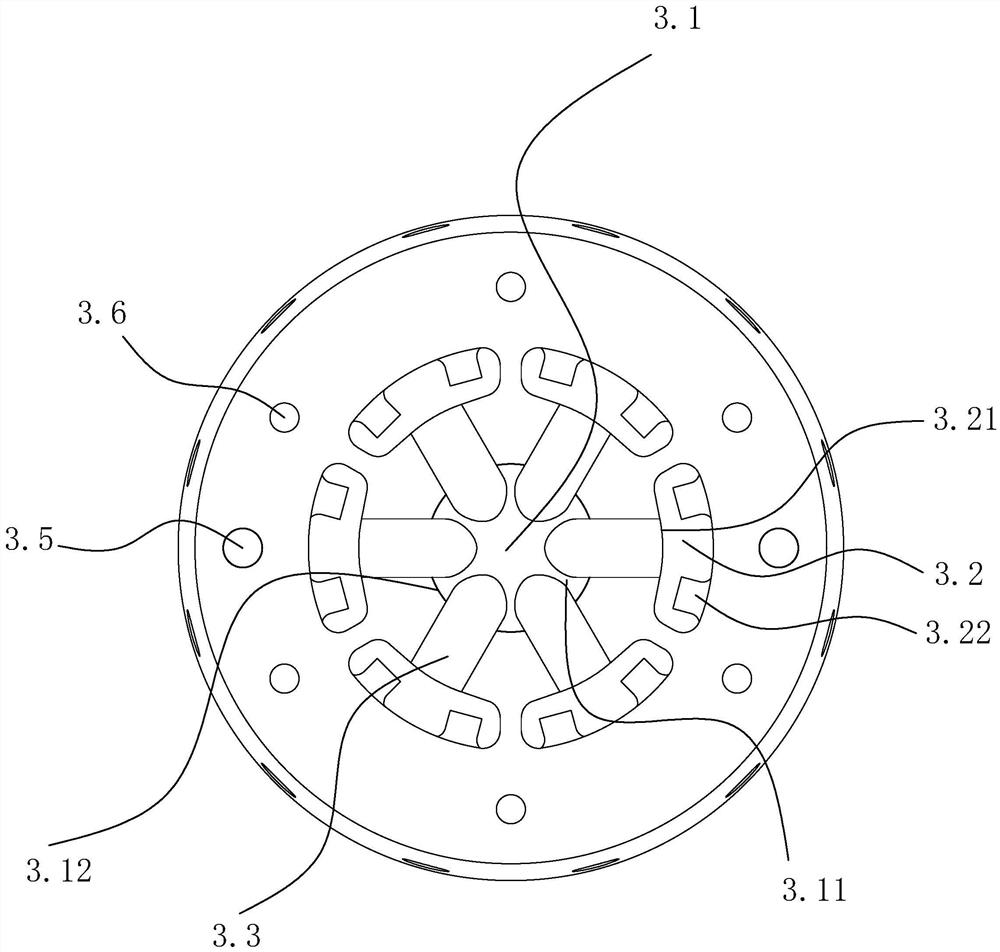

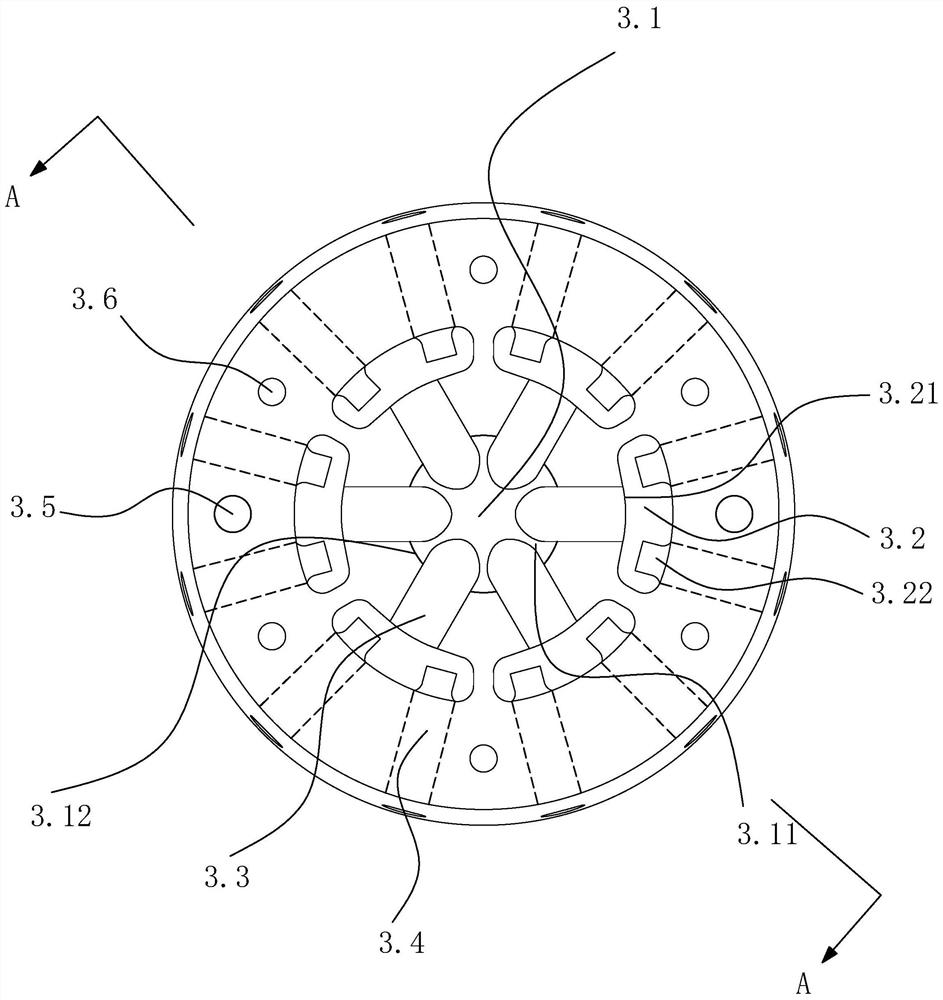

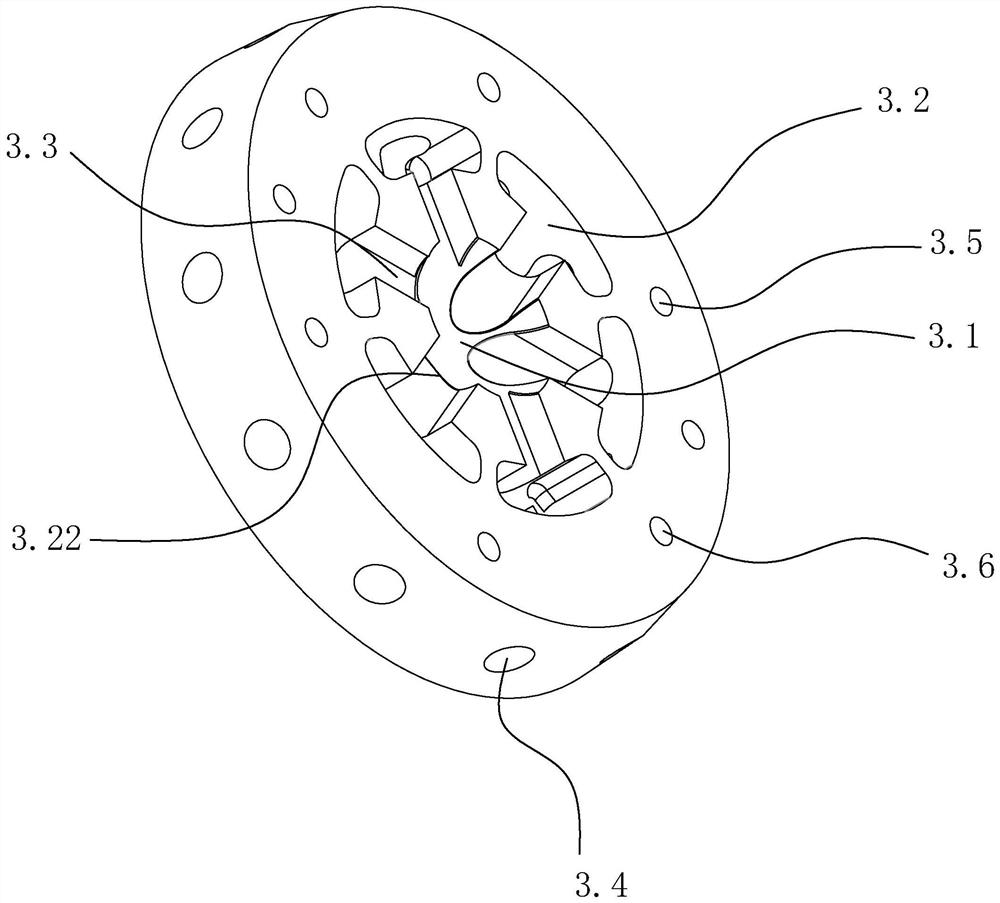

[0035] Example one, e.g., Figure 1 and Figure 2 As shown, an injection mold with an umbrella-like cooling waterway, including the mold body 1, the mold base 2 and the insert 3, the insert 3 is made of beryllium copper material, the mold body is a small and large round table shape, set in the center above the mold base, the insert is round cake-like, The middle is provided with a guide tank 3.1, the guide tank is an upwardly raised semicircle; the two branch pipes 3.2, the two branch pipes are provided with six identical to each other, with the guide tank 3.1 as the center of the uniform distribution in the direction of the circumference, each two branch pipe 2 is provided with an inlet 3.21 towards the guide sink 3.1 and the outlet of the two back guide sinks 3.22; the first branch 3 ends are connected to the inlet 3.1 of the two branch pipes 3.21, a total of six, all uniformly distributed along the radial direction of the same circumference; the second branch 3.4 is provided with...

Embodiment 2

[0042] Example TWO, e.g., Figure 5 As shown, the insert is uniformly provided along the circumference of eight two branch pipes 3.2, eight first branches and sixteen second branches, other settings are the same as Example I, the increased second branch may make the cooling channel more densely distributed, improve the cooling efficiency.

Embodiment 3

[0043] Example THREE, e.g., Figure 6As shown, on the basis of Example 1, the mount surface is provided with an inlet in the middle of the other side of the sink, The water control tank is set in a spherical water control 3.7, the top of the water control ball and the top of the inner wall of the water guide tank 1 are connected by a connecting line, the water control ball is evenly distributed around the six temperature sensing components, the temperature sensing component is connected to the control water ball and the channel wall of the water guide, when it is not working, the thermostat is maintained in the water guide through the connecting line, when the working state, the temperature sensor component with the surrounding temperature change produces obvious expansion and contraction, when due to the speed of raw material flow to each runner or the flow rate is uneven or other factors, resulting in uneven heat in each direction of the glue inlet and the main body of the mold, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com