Vertical double-loop branch line lap joint operation control method for operating robot

A control method and robot technology, applied in overhead lines/cable equipment, equipment for connecting/terminating cables, climate sustainability, etc., can solve problems such as inability to complete operations and low efficiency, and achieve improved operation efficiency, accuracy and efficiency Work, the effect of avoiding the risk of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

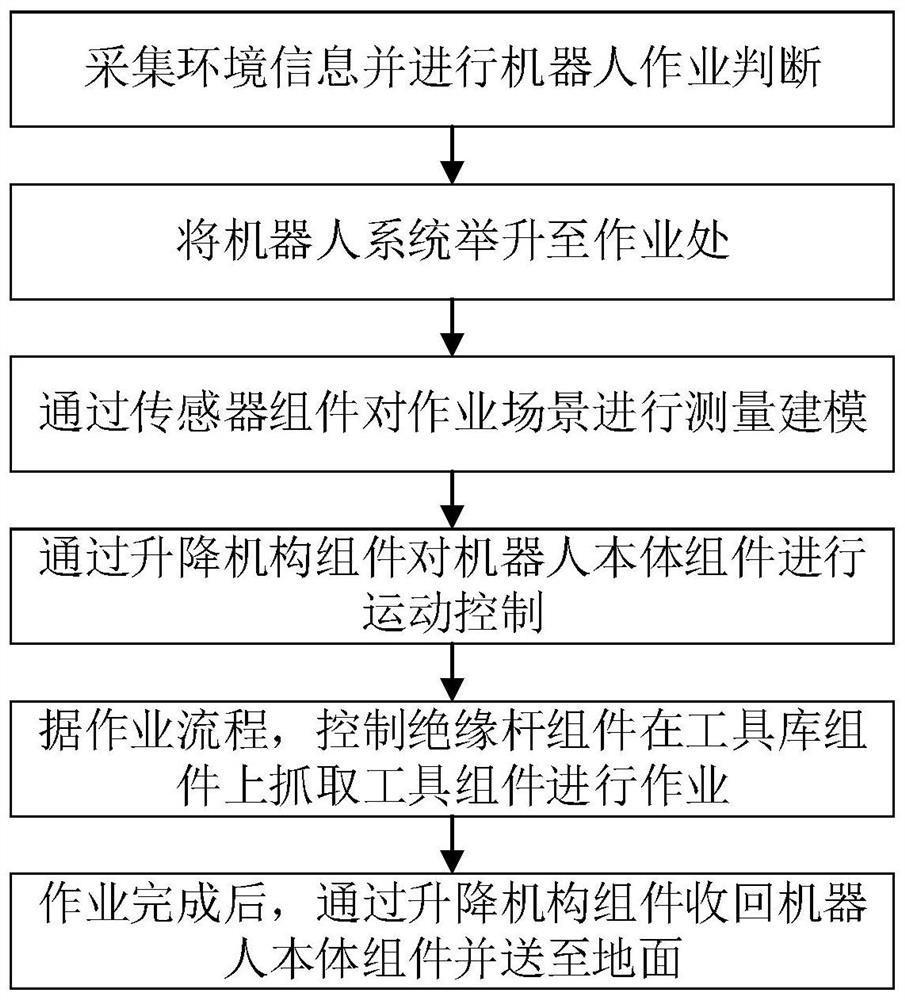

[0031] The technical solutions of the present invention will be further described in detail below through embodiments and in conjunction with the accompanying drawings. Embodiment: A method for controlling the vertical double-loop branch line overlap operation of an operating robot in this embodiment, such as figure 1 shown, including the following steps:

[0032] S1 collects environmental information and performs robot operation judgment. The sensor component 6 is used for the robot system to perceive and model the working environment and operation scene, and is the premise and guarantee for the robot to complete the operation. like Figure 8As shown, the sensor assembly 6 includes a tail monitoring assembly, an area array laser 44 , a 3D laser assembly 48 , and a force sensor assembly 50 . The rear monitoring assembly includes but is not limited to a GPS antenna 46 , a micro weather station 45 , a camera 49 , and a tricolor light 47 . The GPS antenna 46 is used for posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com