Nut inner ring tapping device capable of cleaning table top and using method of nut inner ring tapping device

A tapping device and nut technology, applied in the field of parts processing, can solve the problems of inconvenient use, difficult cleaning, waste of manpower, etc., and achieve the effects of convenient use, convenient tapping operation, and avoiding residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

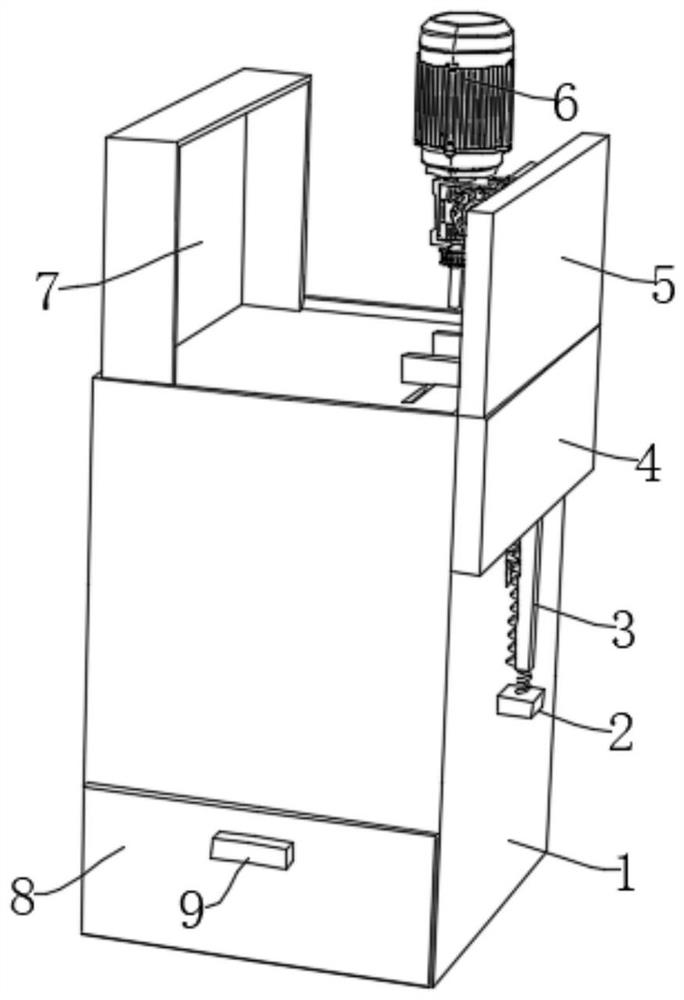

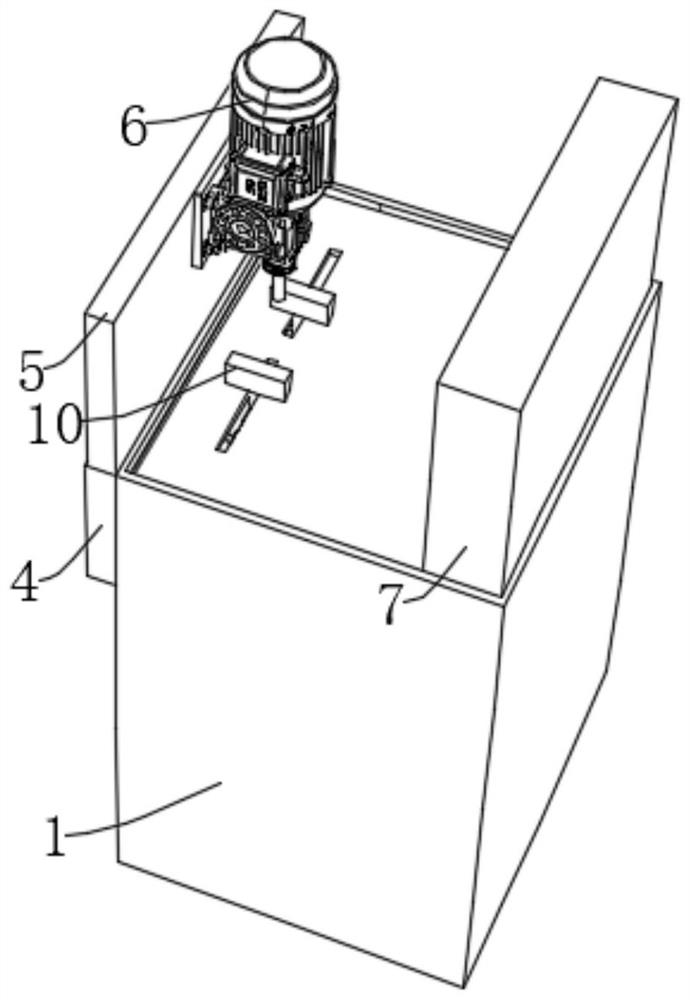

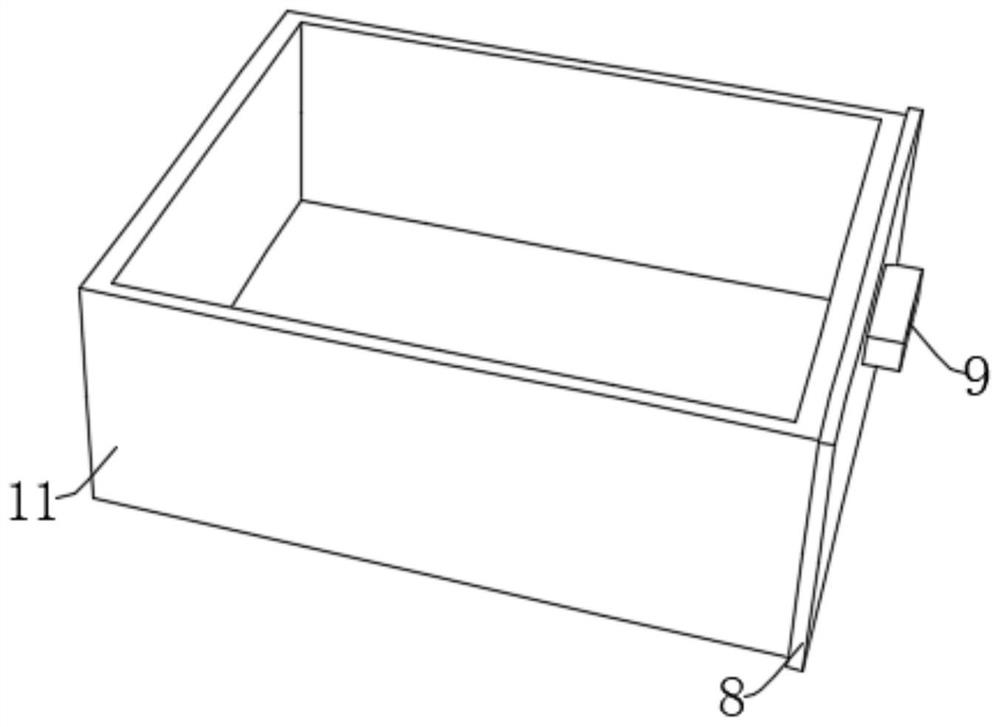

[0033] refer to Figure 1-7 , a nut inner ring tapping device that can clean the table, including a box body 1, one side of the box body 1 is slidably connected with a placement box 4, the top of the placement box 4 is fixedly connected with a mounting plate 5, and one side of the mounting plate 5 A tapping machine 6 is fixedly connected, and a drive assembly for driving the placing box 4 to move in the vertical direction is arranged inside the box body 1;

[0034] The inner walls on both sides of the box body 1 are rotatably connected with the same rotating shaft 19, the outer wall of the rotating shaft 19 is fixedly sleeved with a rotating plate 18, and the bottom of the rotating plate 18 and the inner wall of one side of the box body 1 are fixedly connected with two symmetrically arranged. The bottom of the first spring 20, the turning plate 18 is provided with a clamping assembly for clamping the nut.

Embodiment 2

[0036] refer to Figure 1-7 , a nut inner ring tapping device that can clean the table, including a box body 1, one side of the box body 1 is slidably connected with a placement box 4, the top of the placement box 4 is fixedly connected with a mounting plate 5, and one side of the mounting plate 5 A tapping machine 6 is fixedly connected, and a drive assembly for driving the placement box 4 to move in the vertical direction is arranged inside the box body 1. The drive assembly includes a second servo motor 26 fixedly connected to the inner wall of one side of the box body 1. A rotating rod 27 is fixedly connected to the output shafts of the two servo motors 26 , and a gear 15 is fixedly connected to one end of the rotating rod 27 . One side of the gear 15 extends to the outer wall of the box body 1 . The meshed first rack 3, the outer wall of the box body 1 is fixedly connected with a fixed block 2, and the same tension spring 13 is fixedly connected between the fixed block 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com