Elevator dragging method and equipment

A technology for elevators and equipment, which is applied to elevators, lifting equipment in mines, sustainable buildings, etc., can solve the problems of high operating noise, reduced safety and reliability of elevators, and high energy consumption of elevators, so as to reduce the number of cycles and quantity, reduce The risk of cage shifting and the effect of improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

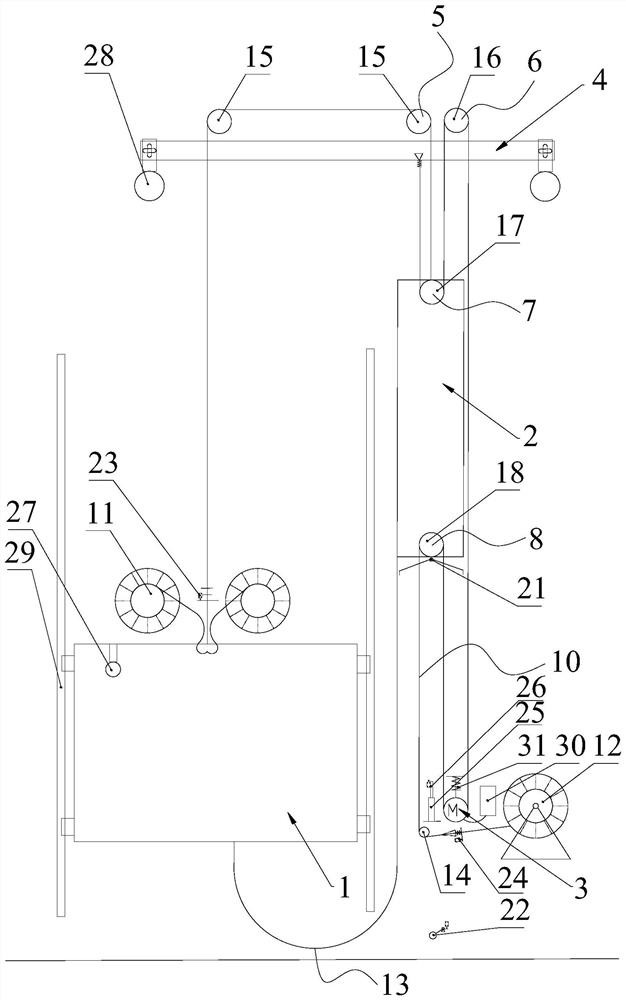

[0037] like figure 1 As shown in the figure, an elevator dragging device includes a cage 1, a counterweight 2, a guide mechanism 29 for the cage and the counterweight to run up and down, a traction machine 3, and a first guide wheel group that are all installed on the hoistway overhead beam 4 5 and the second guide wheel group 6, the cage 1 and the counterweight 2 are located in the hoistway; the traction machine 3 is located on one side of the counterweight 2, and the traction machine 3 can be fixed on the top, bottom, wall or outside of the hoistway , the control system 30 of the traction machine 3 contains an energy feedback device, the traction machine 3 contains a mechanical energy storage device 31, the traction machine is a permanent magnet synchronous gearless or three-phase asynchronous geared form, and the upper end of the counterweight 2 is installed with an upper The wheel set 7, a lower wheel set 8 is installed at the lower end, a locking mechanism 21 is provided ...

Embodiment 2

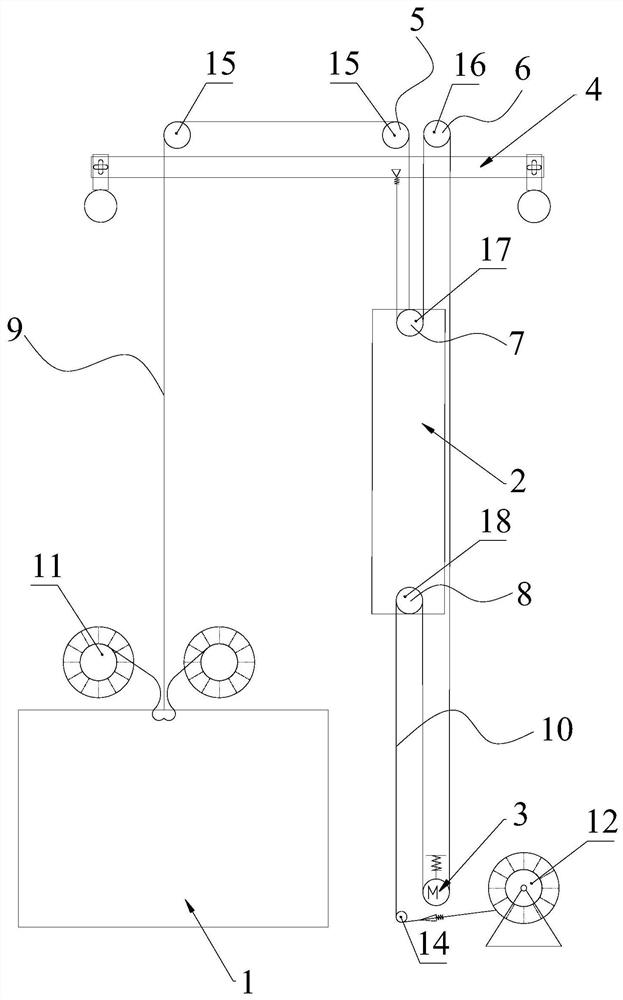

[0051] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that there are two upper wheels 17 and two lower wheels 18 .

Embodiment 3

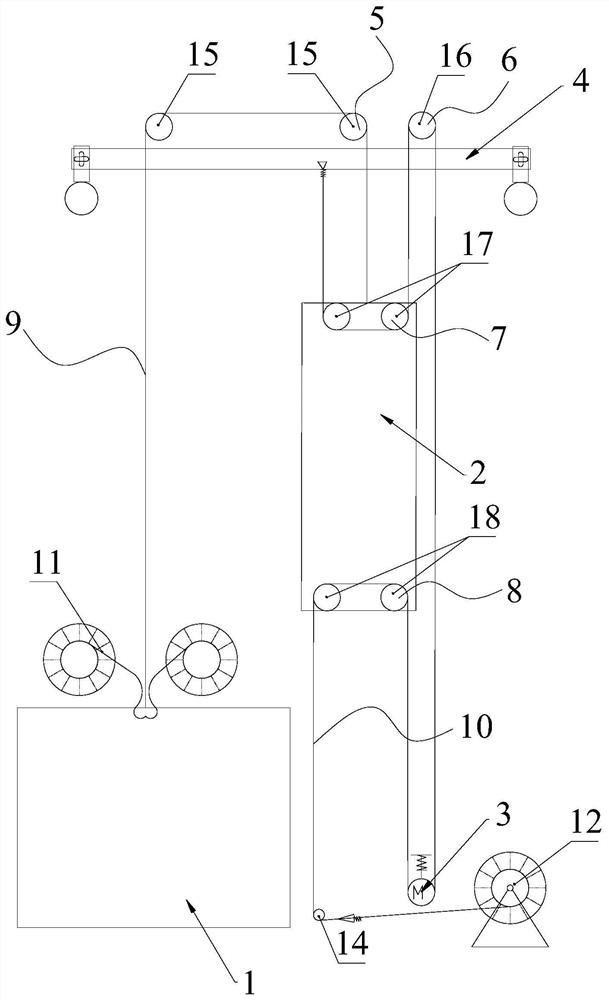

[0053] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 or 2 is that it also includes a third guide wheel group 19 and a fourth guide wheel group 20, the third guide wheel group 19 is installed on the hoistway sky beam 4, and the fourth guide wheel group The group 20 is installed at the lower part of the hoistway, the upper wheel group 7 includes a plurality of upper wheels 17, the lower wheel group 8 includes a plurality of lower wheels 18, the third guide wheel group 19 includes at least one third guide wheel, and the fourth guide wheel group 20 includes At least one fourth guide wheel; one end of the first traction cable 9 is relatively fixed with the hanging cage 1 and connected with the first code disc 11, and the other end of the first traction cable 9 goes up around the first guide wheel group 5 and then goes down Connected with the counterweight 2; one end of the second traction cable 10 is relatively fixed to the bottom of the hoistway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com