Full-automatic cloth paving machine

A cloth spreading machine, fully automatic technology, applied in textiles and papermaking, thin material processing, textile material cutting, etc., can solve the problem of low alignment of cloth, achieve the effect of flat end surface and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

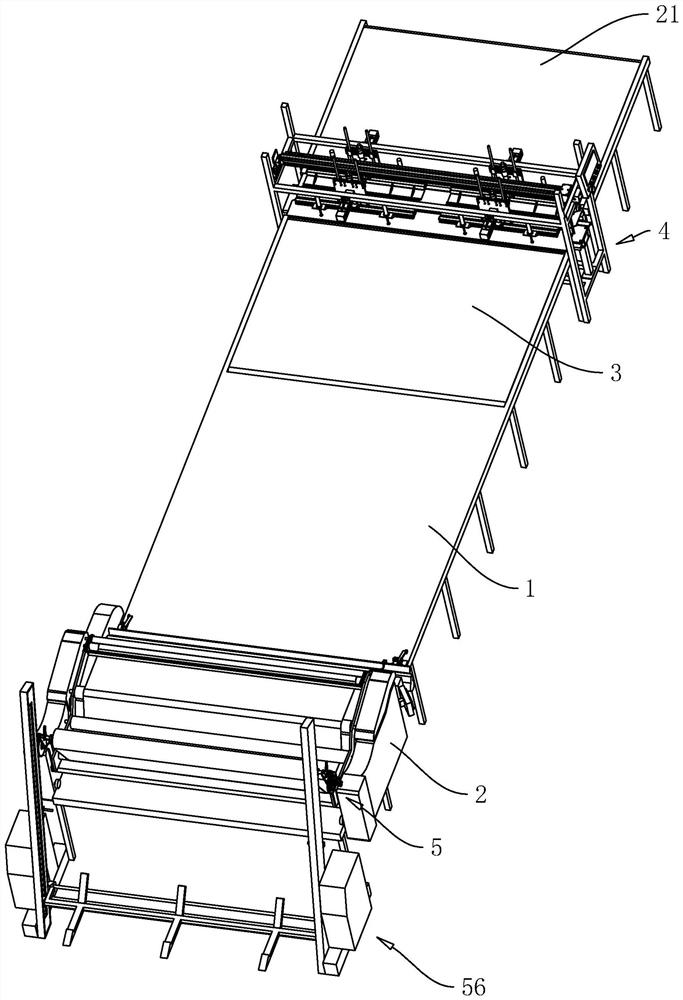

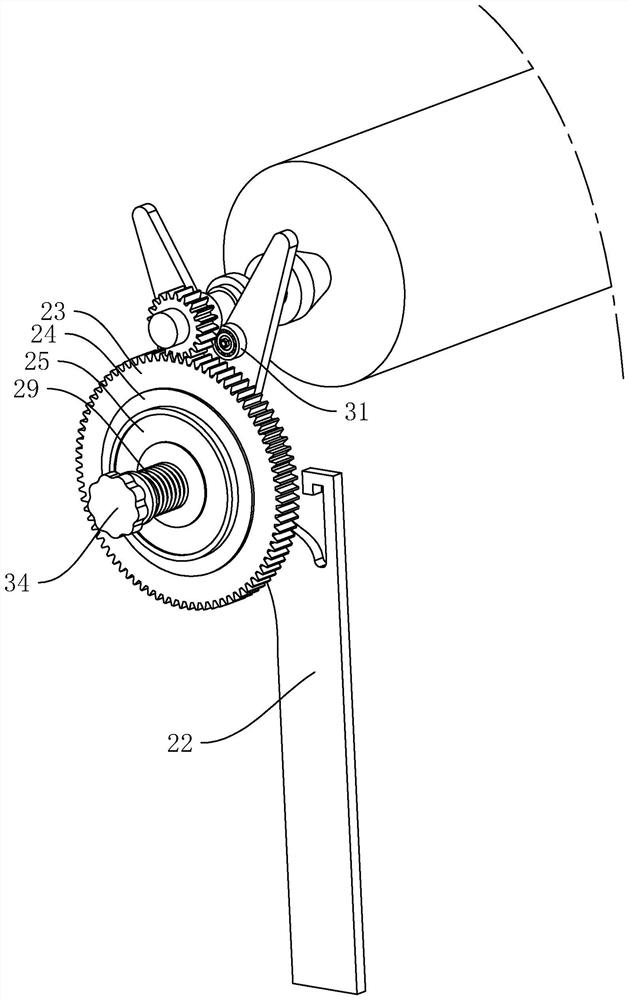

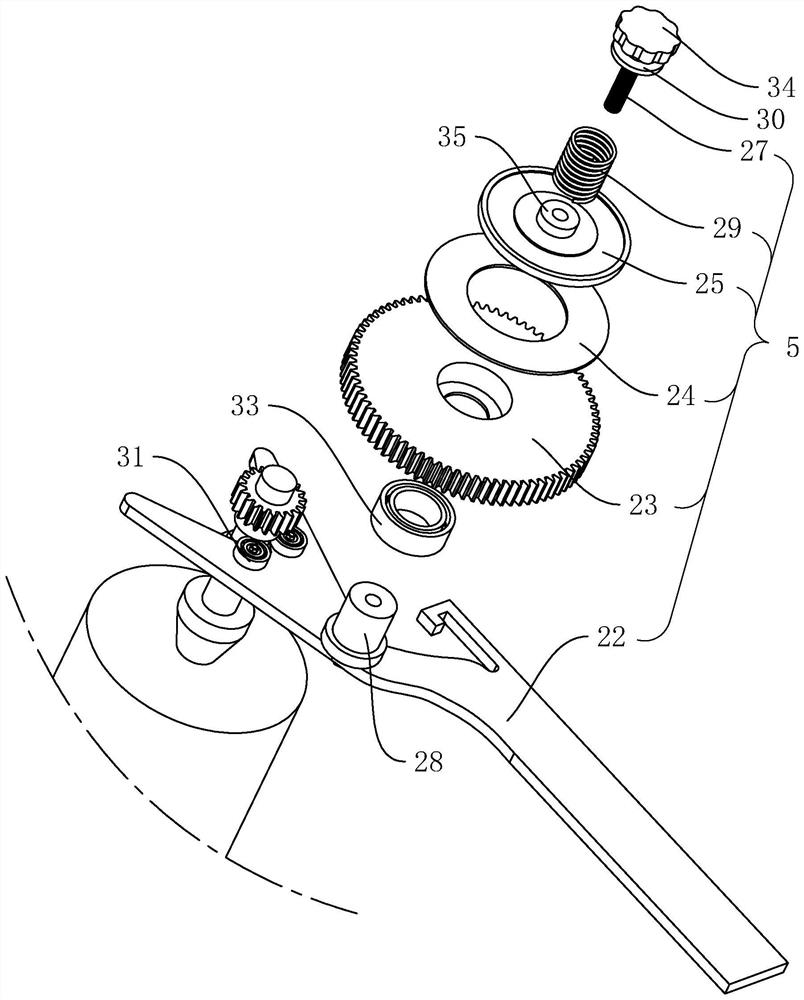

[0051] refer to figure 1 , the embodiment of the present application discloses a fully automatic spreader, which includes a placement rack 1 and a spreader body 2 installed on the placement rack 1 . A first conveyor belt 3 for conveying fabrics is installed on the placement rack 1. The first conveyor belt 3 is located on one side of the placement rack 1. The placement rack 1 is provided with a cutting device 4 for cutting fabrics. The rack 1 is provided with the side of the first conveyor belt 3 . The spreader body 2 is provided with an adjustment device 5 for adjusting the tightness of the cloth when spreading. The adjustment device 5 is located on the side of the spreader body 2 away from the first conveyor belt 3, and the adjustment device 5 is located on the spreader body 2. Away from the side of shelf 1. Adjust the fabric tightness during spreading by the adjusting device 5 , and then cut the flattened fabric by the cutting device 4 so that the end surfaces of the flatt...

Embodiment 2

[0081] refer to Figure 9 and Figure 10 The difference between this embodiment and the first embodiment is that a second driving assembly 67 is installed on the sliding rod 12, and the second driving assembly 67 is located at the end of the sliding rod 12 away from the first driving assembly 11. The second driving assembly The side of 67 away from the sliding rod 12 is installed with a second cutting tool 66 for cutting the cloth, the second driving assembly 67 drives the second cutting tool 66 to move, the first cutting tool 7 and the second cutting tool 66 work simultaneously , and the moving speed of the second cutting tool 66 is different from the moving speed of the first cutting tool 7 .

[0082] When the moving speed of the second cutting blade 66 is lower than the moving speed of the first cutting blade 7, when the first cutting blade 7 cuts the cloth to the middle part and is on the way of returning, the second cutting blade 66 moves to the middle part of the cloth,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com