Copper sheet water stop construction method

A construction method and technology of copper sheet stop, applied in water conservancy projects, marine engineering, infrastructure engineering and other directions, can solve problems such as failure to achieve the expected water stop effect, safety accidents, and easy displacement of copper sheet water stop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] ⑴ Copper sheet water stop performance index and processing

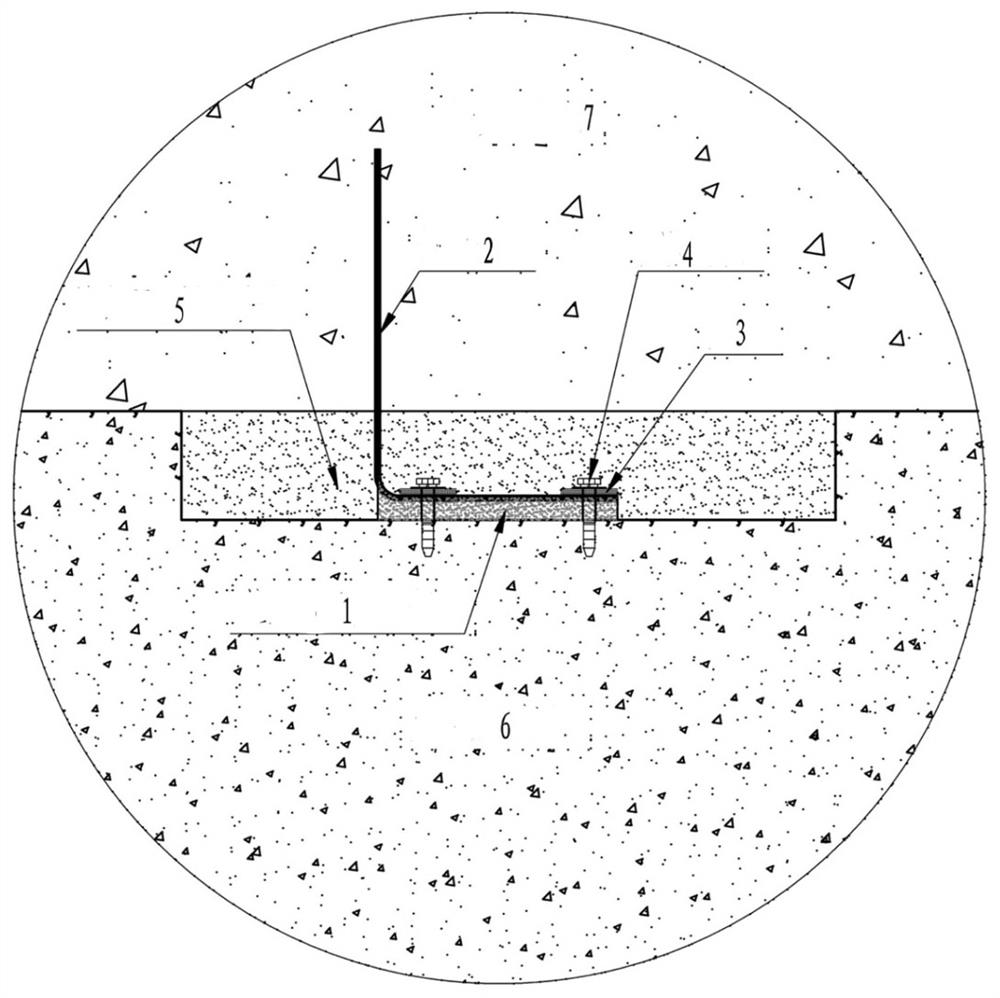

[0018] The thickness of copper sheet water stop 2 is 0.8~1.2mm, the tensile strength is ≥205MPa, and the elongation rate is ≥25%. Its chemical composition and physical and mechanical properties meet GB / T 2059.

[0019] The width of the copper sheet water stop 2 is 500mm, which is bent and formed in the processing plant in advance, and bent 90° from the two-fifth width position, and drill two rows with an electric drill in the copper sheet water stop 2 part embedded in the epoxy resin mortar as required. Hole, hole diameter 20mm, drilling row spacing 100mm, drilling spacing 500mm.

[0020] (2) Construction of water stop groove and expansion bolt hole

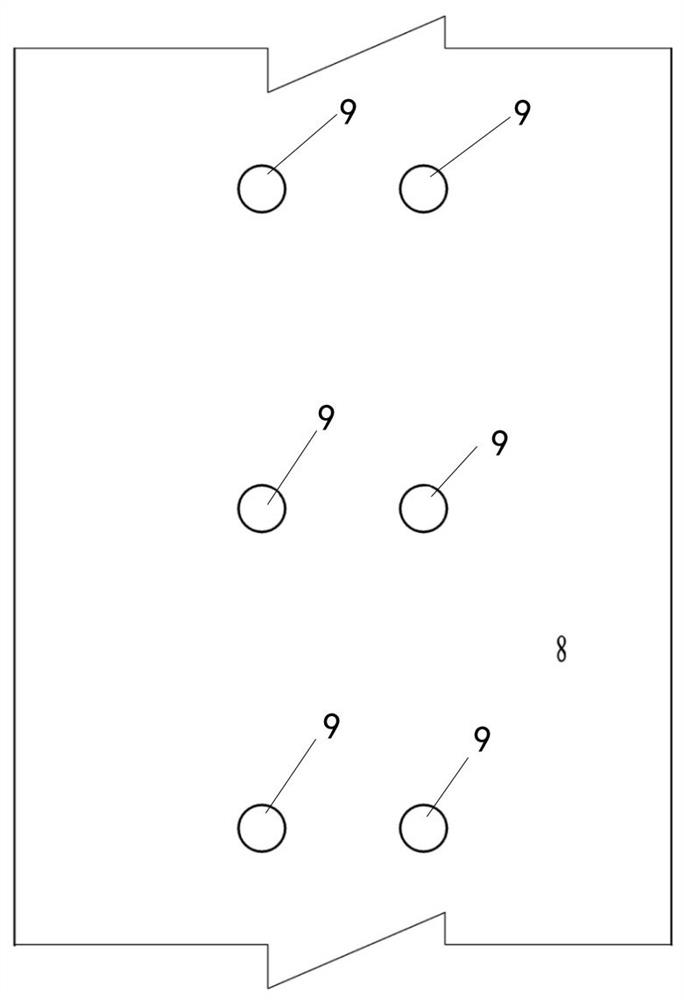

[0021] Before pouring the concrete 6 first, it is necessary to set the water stop position of the copper sheet. First draw a line to determine the range line of the water stop groove 8. The width of the water stop groove is 500mm to 600mm. Use a cutting machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com